Aerial Work Vehicle Hydraulic Cylinders

Aerial work vehicle hydraulic cylinders play a crucial role in scissor-type, mast-type, and arm-type aerial work platforms by providing the lifting and stabilizing force required for safe and efficient operation. In scissor lifts, these cylinders extend and contract to elevate the platform vertically. For mast-type platforms, hydraulic cylinders ensure smooth telescopic movement for precise height adjustments. In arm-type platforms, they enable multi-directional articulation, allowing access to hard-to-reach areas.

Aerial Work Vehicle Hydraulic Cylinder Types

Aerial work vehicle hydraulic cylinders are specialized components designed to provide lifting, stability, and precision in various types of aerial work platforms, including scissor-type, mast-type, and arm-type platforms. Each type of platform utilizes specific hydraulic cylinders tailored to its operational requirements.

- Scissor-type aerial work platform hydraulic cylinders are typically compact yet robust. These scissor lift hydraulic cylinders are positioned to drive the scissor mechanism, extending and contracting to lift or lower the platform in a vertical motion. They are designed to handle heavy loads, ensuring smooth lifting and precise height adjustments. These cylinders are often double-acting, allowing for controlled motion in both directions for enhanced safety and reliability.

- Mast-type aerial work platform hydraulic cylinders are primarily used to extend and retract the mast, enabling vertical movement. These cylinders are often single-acting or telescopic to create a compact design while achieving significant height adjustments. The smooth operation of these cylinders ensures stability and safety, especially in applications requiring precise positioning at elevated heights.

- Arm-type aerial work platform hydraulic cylinders are more complex, as they provide multi-directional articulation. These cylinders include boom lift cylinders, jib cylinders, and stabilizing cylinders, all working together to enable the platform to move vertically, horizontally, and at angles. This versatility allows arm-type platforms to access hard-to-reach areas efficiently.

Scissor Type Aerial Work Platform Hydraulic Cylinders

Mast Type Aerial Work Platform Hydraulic Cylinders

Arm Type Aerial Work Platform Hydraulic Cylinders

Hydraulic Cylinder for Aerial Work Platform

Hydraulic cylinders are a critical component in aerial work platforms, as they provide the primary mechanism for lifting, lowering, and stabilizing the platform during operation. These cylinders are designed to convert hydraulic energy into linear mechanical force, enabling precise and controlled movement essential for safe and efficient work at height. Whether in hydraulic cylinder scissor lifts, mast-type platforms, or arm-type platforms, hydraulic cylinders ensure smooth and reliable operation under varying load and environmental conditions.

In scissor-type aerial work platforms, hydraulic cylinders work by extending and retracting to raise or lower the platform in a vertical motion. The cylinders are strategically placed in a cross-linked arrangement, transferring force to the scissor arms to achieve the desired elevation. Mast-type platforms rely on hydraulic cylinders for telescopic motion, providing vertical reach with enhanced stability and precision. For arm-type aerial work platforms, such as articulating or telescopic booms, hydraulic cylinders not only control vertical movement but also enable multi-directional articulation, allowing the platform to reach hard-to-access areas.

These hydraulic cylinders are engineered to handle heavy loads while ensuring smooth and vibration-free operation. They are built with durable materials to withstand high pressures, extreme weather, and rigorous usage, ensuring longevity and reliability. By providing controlled movement, load stability, and operational safety, hydraulic cylinders are indispensable in aerial work platforms, supporting a wide range of industrial and maintenance tasks.

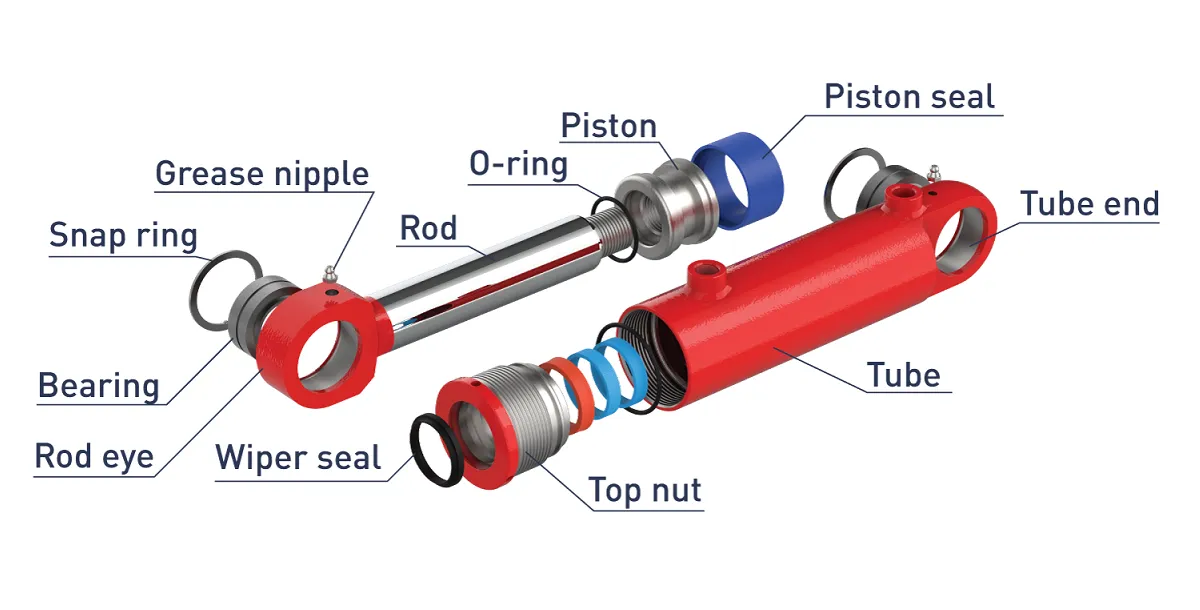

Hydraulic Cylinder Components

- Cylinder Barrel

The hydraulic cylinder barrel is the outer casing that houses the hydraulic piston and fluid. It is designed to withstand high internal pressures, ensuring durability and smooth operation during lifting and lowering tasks. - Piston and Piston Rod

The hydraulic cylinder piston separates the internal compartments of the cylinder, creating pressure differentials for movement. The piston rod connects the piston to the external load, transferring the hydraulic force to lift or adjust the aerial work platform. - Hydraulic Seals

Hydraulic cylinder seals prevent fluid leakage and maintain pressure within the cylinder. They also protect internal components from contaminants such as dirt and debris, ensuring smooth and efficient performance over time. - End Caps

Hydraulic cylinder end caps are located at both ends of the cylinder barrel, providing structural support and sealing the hydraulic system. They also house mounting points, allowing the cylinder to be securely attached to the aerial work vehicle. - Hydraulic Ports

Hydraulic cylinder ports allow the entry and exit of hydraulic fluid into the cylinder. These ports are connected to the hydraulic pump, enabling precise control over the cylinder’s extension and retraction movements. - Rod Eye or Clevis

The hydraulic cylinder rod eye or clevis is attached to the end of the piston rod and serves as the connection point between the cylinder and the moving part of the aerial platform. It allows pivoting motion for flexibility during operation. - Cylinder Tube

The hydraulic cylinder tube is the main body that contains and guides the hydraulic piston. It is made of high-strength materials like steel or stainless steel to resist wear, corrosion, and high-pressure forces.

Features and Benefits

(1) Precise and Smooth Operation

Hydraulic cylinders provide precise and smooth control over the lifting and lowering of aerial work platforms. This ensures stable movement, reducing sudden jerks or vibrations, which enhances safety and operator comfort.

(2) High Load-Bearing Capacity

Hydraulic cylinders are designed to handle heavy loads efficiently, making them suitable for aerial work platforms. They can support substantial weights without compromising performance, ensuring reliability during demanding industrial or construction tasks.

(3) Durability and Longevity

Built with high-strength materials such as steel, hydraulic cylinders are resistant to wear, corrosion, and high pressures. This durability ensures long-term performance, reducing maintenance costs and downtime for aerial work vehicles.

(4) Compact and Efficient Design

Hydraulic cylinders are compact yet powerful, making them ideal for space-constrained applications in aerial work platforms. Their efficient design allows maximum force output without requiring overly large components or systems.

(5) Enhanced Safety Features

Hydraulic cylinders are equipped with safety mechanisms like pressure relief valves and cushioning systems. These features prevent sudden failures or damage, ensuring the safety of operators and the stability of the aerial work platform.

(6) Energy Efficiency

Hydraulic systems use fluid power to transmit energy with minimal losses. Hydraulic cylinders maximize this efficiency by converting hydraulic pressure into mechanical force effectively, reducing energy consumption while maintaining consistent and powerful performance.

Aerial Work Platform Hydraulic Cylinder Applications

-

Municipal Electric Power Maintenance

Hydraulic cylinders in aerial work platforms are widely used for repairing and maintaining electrical power lines and transformers. They provide stable and precise lifting, allowing workers to safely access elevated electrical equipment. -

Street Light and Traffic Signal Repair

For light repairing tasks, such as fixing or replacing streetlights and traffic signals, hydraulic cylinders ensure smooth elevation and stability. This allows technicians to perform their work efficiently and without disruptions. -

Advertising Installation and Maintenance

In the advertising industry, hydraulic cylinders enable aerial work platforms to lift workers and materials for the installation and maintenance of large billboards, banners, and digital displays at significant heights. -

Photography and Communication Equipment Setup

Hydraulic cylinders are essential in elevating platforms for photography and communication tasks, such as setting up cameras, installing antennas, or repairing communication towers. They provide safe and reliable access to elevated positions.

-

Gardening and Tree Maintenance

In gardening and landscaping, hydraulic cylinders help operate platforms for trimming tall trees, pruning branches, or installing decorative elements. They ensure precise positioning and safe operation in outdoor environments. -

Transportation Infrastructure Maintenance

Hydraulic cylinders are used in platforms for inspecting and repairing bridges, overpasses, and tunnels. They allow engineers to work at various heights with stability, ensuring the safety and longevity of transportation infrastructure. -

Industrial and Mining Applications

In industrial and mining environments, hydraulic cylinders are used in aerial platforms for equipment maintenance, structural inspections, and repairs. They ensure safe access to difficult-to-reach areas in high-risk settings. -

Dock and Port Operations

For docks and ports, hydraulic cylinders help in maintaining cranes, loading equipment, and lighting systems. They allow workers to access elevated areas safely, ensuring smooth and efficient operations in maritime logistics.

Municipal Electric Power Maintenance

Street Light and Traffic Signal Repair

Industrial and Mining Applications

Photography and Communication Equipment Setup

Advertising Installation and Maintenance

Transportation Infrastructure Maintenance

Select a Aerial Work Platform Hydraulic Cylinder

- Bore Diameter

The bore diameter determines the force output of the hydraulic cylinder. A larger bore diameter provides higher lifting capacity, making it crucial to match the cylinder’s power to the platform’s load requirements. - Rod Diameter

The rod diameter affects the cylinder’s strength and stability during operation. A thicker rod enhances durability and prevents bending under heavy loads, ensuring reliable performance for aerial work platforms. - Working Pressure

The working pressure defines the hydraulic system’s ability to handle force. Selecting a cylinder with an appropriate pressure rating ensures safe and efficient operation without risking damage to components. - Installation Distance

The installation distance refers to the mounting dimensions of the cylinder. It is essential to choose a cylinder with proper mounting points to ensure a secure and stable connection to the platform. - Stroke Length

The stroke length determines the maximum travel distance of the piston rod. It must match the height requirements of the aerial work platform to achieve the desired range of motion. - Ports

The type, size, and placement of hydraulic ports influence fluid flow and system compatibility. Choose cylinders with ports that align with the aerial platform’s hydraulic system to ensure seamless integration. - Seals

High-quality seals prevent fluid leakage and protect the cylinder from contaminants. Selecting durable and temperature-resistant seals ensures long-term reliability and reduces maintenance costs in demanding work environments. - Material

The cylinder’s material affects its strength, weight, and corrosion resistance. Steel or stainless steel cylinders are ideal for aerial work platforms as they provide durability and withstand harsh operating conditions.

Scissor Lift Hydraulic Cylinder

Boom Lift Hydraulic Cylinder

Custom Hydraulic Cylinders

As a leading aerial work platform hydraulic cylinder manufacturer and supplier, we specialize in delivering a wide range of premium-quality products tailored to meet the diverse needs of aerial work vehicles. Our hydraulic cylinders are meticulously engineered for seamless compatibility with various platform models, ensuring optimal performance, exceptional durability, and unmatched reliability under demanding conditions. With advanced manufacturing techniques and high-grade materials, we guarantee precise functionality and long service life. Contact us today for your custom hydraulic cylinder solutions and receive a personalized quotation tailored to your requirements!

Our Customer Reviews

“These hydraulic cylinders are built to last. Our construction projects require equipment that can handle heavy loads and rough conditions, and these cylinders have been flawless. Their durability and smooth performance are unmatched, making operations seamless and efficient.”

—–United States Customer

“These aerial work platform hydraulic cylinders are robust and reliable. We operate in a high-demand logistics facility, and they’ve consistently performed well without failure. Maintenance is straightforward, saving us time and costs. Truly a great product for industrial use.”

—–German Customer

—–Australian Customer

—–United Kingdom Customer

—–Italian Customer

—–Canadian Customer