WPWEDK Worm Gear Reducers/Worm Gearbox

WPWEDK worm gear reducers, commonly referred to as double reduction worm gearboxes, are advanced mechanical systems engineered for high-efficiency power transmission in a wide range of industrial applications. These worm reducer gearboxes combine a single-stage worm gearbox with a universal gearbox, creating a compact, double-stage reduction system that delivers enhanced torque output and performance. With a single-stage speed ratio range of 1:10 to 1:60 and a double-stage configuration offering ratios from 1:200 to 1:900, they are ideal for operations requiring substantial speed reduction and high torque.

WPWEDK worm gear reducers, commonly referred to as double reduction worm gearboxes, are advanced mechanical systems engineered for high-efficiency power transmission in a wide range of industrial applications. These worm reducer gearboxes combine a single-stage worm gearbox with a universal gearbox, creating a compact, double-stage reduction system that delivers enhanced torque output and performance. With a single-stage speed ratio range of 1:10 to 1:60 and a double-stage configuration offering ratios from 1:200 to 1:900, they are ideal for operations requiring substantial speed reduction and high torque.

Their robust construction ensures durability, smooth operation, and minimal noise, making them suitable for demanding industries like plastics manufacturing, metallurgy, mining, construction, beverage production, and chemical processing. Additionally, their compact design allows seamless integration into machinery, while their energy-efficient and reliable performance ensures consistent operation under challenging conditions. These worm gear speed reducers are valued for their adaptability and ability to enhance productivity in diverse environments.

WPWEDK Worm Gear Reducer Specifications

| Type: | WPWEDK Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

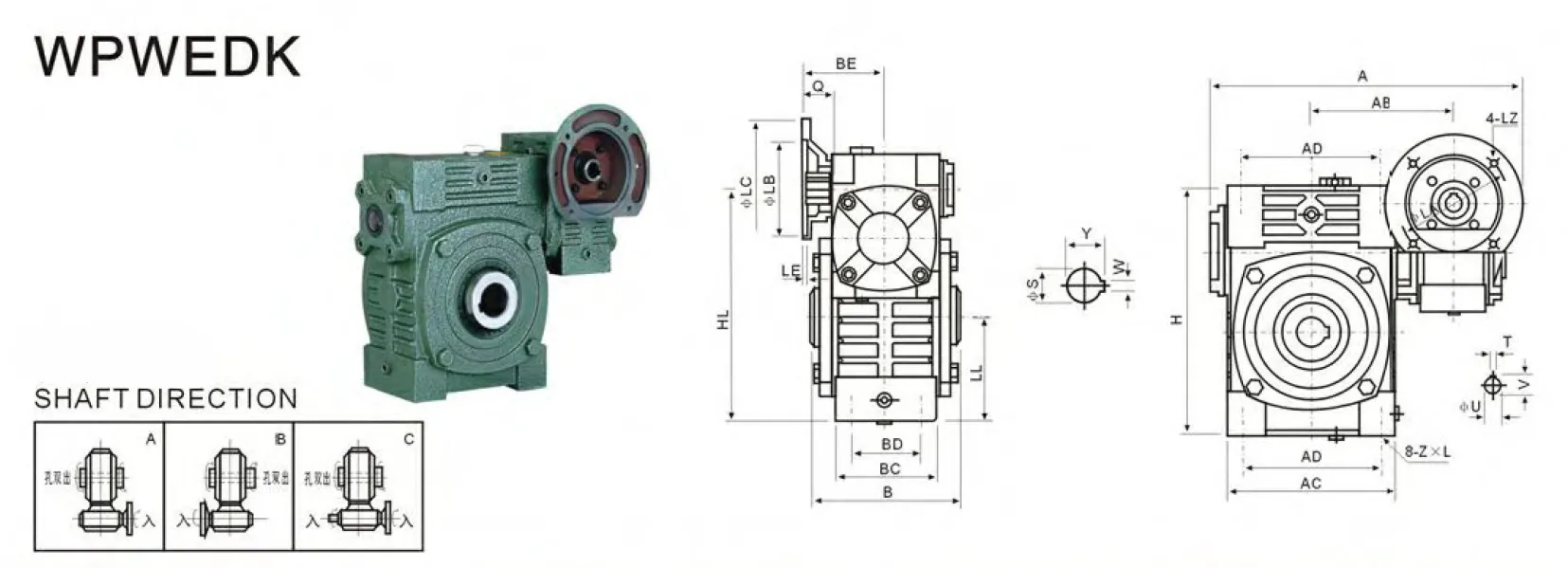

WPWEDK Worm Gearbox Dimensions

| Model | Power (kW) | Ratio | A | AB | B | BE | AC | BC | AD | BD | HL | LL | H | ZXL |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 0.12 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 .... | 314 | 153 | 130 | 75 | 152 | 86 | 125 | 65 | 200 | 90 | 215 | M10×25 |

| 50-80 | 0.18 | 314 | 144 | 150 | 83 | 169 | 102 | 140 | 70 | 235 | 105 | 250 | M12×28 | |

| 60-100 | 0.37 | 387 | 175 | 160 | 91 | 216 | 117 | 180 | 90 | 290 | 130 | 310 | M12×30 | |

| 70-120 | 0.37 | 425 | 193 | 175 | 109 | 256 | 124 | 220 | 100 | 345 | 155 | 370 | M14×32 | |

| 80-135 | 0.75 | 499 | 226 | 210 | 125 | 296 | 147 | 260 | 110 | 400 | 185 | 425 | M16×35 | |

| 100-155 | 1.5 | 570 | 269 | 256 | 148 | 345 | 185 | 280 | 120 | 458 | 203 | 461 | M16×35 | |

| 120-175 | 2.2 | 631 | 287 | 282 | 181 | 374 | 192 | 320 | 140 | 518 | 223 | 521 | M16×35 | |

| 135-200 | 3.0 | 680 | 318 | 320 | 202 | 412 | 230 | 360 | 150 | 580 | 245 | 575 | M20×36 | |

| 155-250 | 5.5 | 815 | 380 | 400 | 247 | 500 | 285 | 420 | 190 | 705 | 300 | 700 | M24×42 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 30 | 35 | 8×33.3 | 18 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 35 | 35 | 10×38.3 | 28 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 40 | 40 | 12×43.3 | 44 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 40 | 40 | 12×43.3 | 44 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 45 | 45 | 14×48.8 | 66 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 60 | 60 | 18×64.4 | 101 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 70 | 70 | 20×74.9 | 139 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 80 | 65 | 22×85.4 | 196 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 70 | 22×90.4 | 285 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 90 | 28×116.4 | 450 |

WPWEDK Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWEDK Double Reduction Worm Reducer Gearbox Benefits

- High Efficiency and Performance

The WPWEDK worm gear reduction gearboxes are designed for exceptional efficiency, combining a single-stage worm gearbox with a universal gearbox for double-stage reduction. This configuration ensures superior torque output and consistent performance, even in applications requiring heavy-duty operations and prolonged use. - Wide Speed Reduction Range

With single-stage speed ratios ranging from 1:10 to 1:60 and double-stage ratios from 1:200 to 1:900, these worm gear drive gearboxes provide incredible flexibility. This versatility makes them suitable for applications needing precise speed control alongside significant reductions in rotational speed. - Compact and Space-Saving Design

The WPWEDK worm gearbox reducers feature a compact structure that enables easy integration into machinery with limited space. Despite their small size, they deliver exceptional power and performance, making them ideal for industries where equipment space is at a premium. - Durability and Longevity

Built with high-quality materials and a robust design, worm reduction gearboxes are engineered to withstand harsh operating environments. Their durability ensures a long service life, making them a reliable and cost-effective solution for demanding industrial applications. - Smooth and Low-Noise Operation

These worm and wheel gearboxes offer smooth operation with minimal vibration and noise. This is particularly beneficial in industries such as food processing and plastics manufacturing, where quieter machinery contributes to a more efficient and comfortable working environment. - Energy-Efficient and Reliable

WPWEDK worm gear reducer gearboxes are optimized for energy efficiency, reducing power consumption while maintaining excellent performance. Their reliable operation ensures consistent output in various industrial settings, including mining, metallurgy, construction, and chemical processing, even under challenging conditions.

WPWEDK Double Reduction Worm Gearbox Applications

- Plastics Industry

WPWEDK double reduction worm gearboxes are widely used in plastics processing equipment like extruders and injection molding machines. Their high torque output and precise speed control ensure efficient material handling. The compact design allows seamless integration into complex machinery, enhancing productivity and reliability in demanding production environments. - Metallurgy Industry

In metallurgical applications, worm drive reduction gearboxes drive heavy-duty equipment such as rolling mills and conveyors. Their robust construction withstands harsh conditions, delivering consistent high torque. The double-stage reduction provides precise speed ratios, enabling efficient metal processing while maintaining durability and minimizing maintenance in high-temperature, high-load settings. - Beverage Industry

WPWEDK worm gear reducers are integral to beverage production lines, powering bottling and packaging machines. Their smooth operation and high efficiency ensure consistent performance. The ability to achieve high reduction ratios supports precise control, reducing energy consumption and ensuring reliable output in fast-paced, high-volume manufacturing processes. - Mining Industry

In mining operations, worm gear speed reducers drive equipment like crushers and conveyor systems. Their high torque and compact design handle heavy loads effectively. The durable build resists dust and vibration, ensuring long-term reliability. These gearboxes optimize speed control, enhancing efficiency in rugged, resource-intensive mining environments. - Construction Industry

WPWEDK worm reduction gearboxes are used in construction machinery, such as cranes and mixers, due to their high torque and compact structure. They provide reliable power transmission under heavy loads. The double-stage reduction ensures precise speed control, improving operational efficiency and safety in dynamic construction sites. - Chemical Industry

In chemical processing, worm reducer gearboxes power mixers, pumps, and reactors. Their corrosion-resistant design and high efficiency suit harsh chemical environments. The precise speed reduction supports accurate process control, ensuring consistent product quality. These gearboxes enhance reliability and energy efficiency in complex chemical manufacturing operations.

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Mining and Quarrying Industry |

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Construction Industry |

Worm Gear Speed Reducer Maintenance

- Regular Lubrication

Ensure the worm gear speed reducer is adequately lubricated with the recommended oil type to minimize friction and wear. Check oil levels monthly and replace lubricant every 6-12 months, depending on usage. Proper lubrication extends gearbox life and maintains optimal performance in demanding applications. - Inspect for Leaks

Routinely examine the worm reducer gearbox for oil leaks around seals and gaskets. Leaks can lead to insufficient lubrication, causing overheating and component damage. Address any leaks promptly by replacing worn seals or tightening connections to ensure reliable operation and prevent costly downtime in industrial settings. - Monitor Temperature

Check the worm drive gearbox’s operating temperature regularly to detect overheating, which can indicate overloading or insufficient lubrication. Use infrared thermometers for accurate readings. If temperatures exceed manufacturer specifications, investigate and resolve issues promptly to prevent gear wear and maintain efficiency in high-torque applications. - Check for Vibration and Noise

Listen for unusual noises or vibrations during operation, as these may signal misalignment or worn components. Perform weekly inspections and use vibration analysis tools if available. Addressing issues early prevents major failures, ensuring smooth performance in industries like mining or metallurgy. - Clean the Exterior

Keep the worm and wheel gearbox exterior free of dust, debris, and corrosive substances, especially in harsh environments like chemical or mining industries. Clean monthly using a soft cloth and non-corrosive cleaner. This prevents contamination and ensures proper heat dissipation, prolonging the gearbox’s operational life and reliability. - Inspect Gears and Bearings

Periodically inspect gears and bearings for signs of wear, pitting, or damage, ideally every six months. Replace worn components promptly to avoid performance degradation. Regular maintenance checks ensure the worm gear reduction gearbox delivers consistent torque and efficiency in applications like plastics or beverage production.

Additional information

| Edited by | Yjx |

|---|