WPWEK Worm Gear Reducers/Worm Gearbox

WPWEK worm gear reducers, also known as double reduction worm gearboxes, are highly efficient and compact mechanical devices designed for a wide range of industrial applications. They feature a distinctive double-stage configuration, which combines a single-stage worm gearbox with a universal gearbox to provide exceptional performance, durability, and flexibility. This makes these worm gear speed reducers ideal for applications requiring substantial speed reduction and high torque output, such as those in plastics, metallurgy, mining, construction, beverages, and chemical industries.

WPWEK worm gear reducers, also known as double reduction worm gearboxes, are highly efficient and compact mechanical devices designed for a wide range of industrial applications. They feature a distinctive double-stage configuration, which combines a single-stage worm gearbox with a universal gearbox to provide exceptional performance, durability, and flexibility. The single-stage gearbox offers speed reduction ratios ranging from 1:10 to 1:60, while the double-stage design achieves significantly higher ratios, from 1:200 to 1:900, by multiplying the ratios of two single-stage setups.

This makes these worm gear speed reducers ideal for applications requiring substantial speed reduction and high torque output, such as those in plastics, metallurgy, mining, construction, beverages, and chemical industries. Their robust construction ensures they can handle demanding loads in compact spaces, while their precision engineering minimizes maintenance requirements. These worm reducer gearboxes enhance productivity by delivering reliable and long-lasting operation in challenging environments.

WPWEK Worm Gear Reducer Specifications

| Type: | WPWEK Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

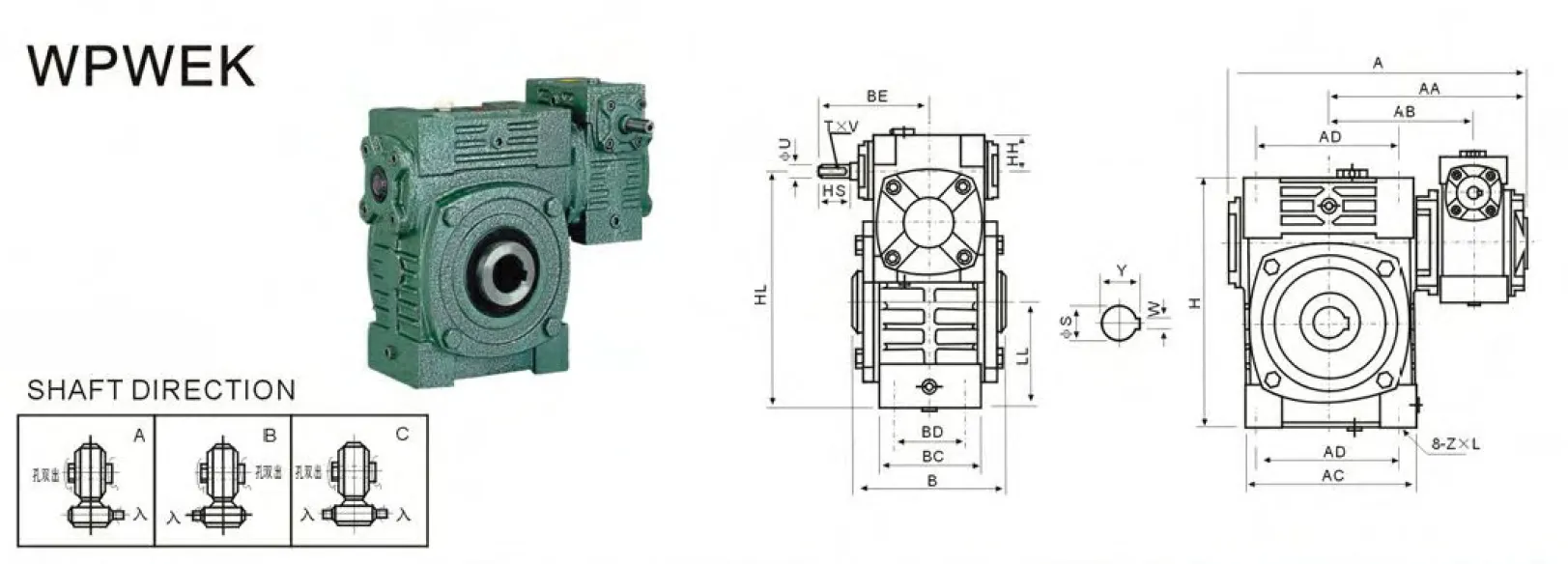

WPWEK Worm Gearbox Dimensions

| Model | Ratio | A | AA | AB | B | BE | AC | BC | AD | BD | HH | HL | LL | H | ZXL |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 .... | 286 | 195 | 153 | 130 | 87 | 152 | 86 | 125 | 65 | 35 | 200 | 90 | 215 | M10×25 |

| 50-80 | 297 | 197 | 144 | 150 | 108 | 169 | 102 | 140 | 70 | 35 | 235 | 105 | 250 | M12×28 | |

| 60-100 | 363 | 231 | 175 | 160 | 120 | 216 | 117 | 180 | 90 | 42 | 290 | 130 | 310 | M12×30 | |

| 70-120 | 408 | 256 | 193 | 175 | 140 | 256 | 124 | 220 | 100 | 55 | 345 | 155 | 370 | M14×32 | |

| 80-135 | 471 | 298 | 226 | 210 | 160 | 296 | 147 | 260 | 110 | 65 | 400 | 185 | 425 | M16×35 | |

| 100-155 | 555 | 354 | 269 | 256 | 190 | 345 | 185 | 280 | 120 | 80 | 458 | 203 | 461 | M16×35 | |

| 120-175 | 598 | 379 | 287 | 282 | 219 | 374 | 192 | 320 | 140 | 95 | 518 | 223 | 521 | M16×35 | |

| 135-200 | 662 | 425 | 318 | 320 | 256 | 412 | 230 | 360 | 150 | 105 | 580 | 245 | 575 | M20×36 | |

| 155-250 | 795 | 510 | 380 | 400 | 295 | 500 | 285 | 420 | 190 | 103 | 705 | 300 | 700 | M24×42 |

| Input hole | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 30 | 8×33.3 | 17 |

| 30 | 12 | 4×2.5 | 35 | 10×38.3 | 28 |

| 40 | 15 | 5×3 | 40 | 12×43.3 | 43 |

| 40 | 18 | 5×3 | 45 | 14×48.8 | 64 |

| 50 | 22 | 7×4 | 60 | 18×64.4 | 99 |

| 50 | 25 | 7×4 | 70 | 20×74.9 | 136 |

| 65 | 30 | 7×4 | 80 | 22×85.4 | 193 |

| 75 | 35 | 10×4.5 | 85 | 22×90.4 | 280 |

| 85 | 40 | 12×5 | 110 | 28×116.4 | 442 |

WPWEK Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWEK Double Reduction Worm Gearbox Advantages

- High Reduction Ratios

The WPWEK double reduction worm gearbox offers exceptionally high speed reduction ratios, ranging from 1:200 to 1:900. This makes it suitable for applications requiring significant deceleration with precision, ensuring efficient performance in industries that demand both speed control and torque multiplication. - Compact and Space-Saving Design

Built with a compact double-stage configuration, the worm reducer gearbox is ideal for installations with limited space. Its small footprint allows it to be integrated into tight setups without compromising power output or efficiency, making it a versatile solution for modern machinery. - Durable and Robust Construction

Engineered with premium materials and advanced machining processes, the WPWEK worm gear speed reducer is designed to withstand heavy loads and harsh environments. Its durability ensures long-lasting performance under demanding conditions, significantly reducing the likelihood of breakdowns and maintenance requirements. - High Torque Output

The double-stage reduction setup enhances torque output, making the double reduction worm gear reducer suitable for heavy-duty applications. It delivers consistent power even in operations involving high loads, such as metal processing, mining, or plastic extrusion, ensuring reliable and powerful performance. - Versatility Across Industries

WPWEK worm gear reduction gearboxes are widely used in various industries, including construction, metallurgy, beverages, and chemicals. Their ability to adapt to different operational needs, combined with their efficiency and reliability, makes them a preferred choice for diverse industrial applications. - Low Maintenance and High Efficiency

The precision engineering of the worm gearbox reducer minimizes wear and tear, reducing the need for frequent maintenance. Its optimized design ensures high operational efficiency, cutting down energy consumption and downtime, thereby improving overall productivity and cost-effectiveness for businesses.

WPWEK Worm Drive Reduction Gearbox Applications

- Plastics Industry

In the plastics industry, WPWEK worm gear reduction gearboxes are used in extrusion machines and injection molding equipment. Their high torque output and precise speed control ensure consistent operation, enabling efficient material processing and enhancing the quality of molded or extruded plastic products. - Metallurgy and Metal Processing

Worm reducer gearboxes are vital in metallurgical applications, including rolling mills, furnaces, and metal cutting machines. Their robust design handles heavy loads and high temperatures effectively, ensuring smooth operation and reliability in the demanding environments of metal production and processing. - Mining and Quarrying Industry

The mining sector relies on WPWEK worm gear reducers for conveyors, crushers, and hoisting systems. Their ability to deliver high torque and withstand harsh environmental conditions makes them ideal for managing heavy-duty operations and ensuring uninterrupted productivity in mining and quarrying applications. - Beverage and Food Processing

In beverage and food processing, worm gear speed reducers are utilized in mixers, conveyors, and packaging machinery. Their precision and efficiency help maintain consistent production speeds, ensuring hygienic handling and processing while meeting industry standards for food safety and quality control. - Construction and Material Handling

WPWEK worm drive gearboxes are extensively used in construction equipment such as cranes, hoists, and cement mixers. Their compact design and high-performance capabilities make them suitable for handling heavy materials, ensuring reliable operation in the rigorous demands of construction projects. - Chemical Industry

The chemical industry benefits from worm gear reducer gearboxes in agitators, pumps, and reactors. Their ability to provide stable and precise speed control ensures safe and efficient handling of sensitive or hazardous materials, improving productivity while maintaining safety in chemical production processes.

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Construction Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Conveyor Equipment |

WPWEK Worm Gear Reducer Precautions for Use

- Proper Installation and Alignment

Ensure the worm gear drive gearbox is installed on a stable, vibration-free surface with precise alignment between the input and output shafts. Misalignment can lead to increased wear, inefficiency, and potential damage to internal components, reducing the gearbox’s lifespan and performance. - Lubrication and Maintenance

Regularly check and maintain the lubrication levels as specified in the manufacturer’s guidelines. Using the correct grade of lubricant and replacing it periodically ensures smooth operation, reduces friction, and prevents overheating or premature wear of the gearbox’s internal components. - Load Capacity Adherence

Avoid exceeding the worm gearbox reducer’s rated load capacity during operation. Excessive loads can cause overheating, accelerated wear, or even failure of internal gears. Proper load management is essential to ensure the long-term reliability and efficiency of the gearbox. - Monitoring Operating Temperature

Keep the worm and wheel gearbox within its recommended temperature range during operation. High temperatures can indicate overloading, insufficient lubrication, or improper usage. Monitoring and addressing temperature fluctuations promptly can prevent damage and extend the gearbox’s operational life. - Avoiding External Contaminants

Protect the worm reduction gearbox from dirt, moisture, and corrosive substances that may enter and damage internal components. Installing protective covers or seals and maintaining a clean operating environment can minimize contamination risks and maintain optimal performance. - Regular Inspection and Replacement of Parts

Conduct periodic inspections to identify signs of wear, misalignment, or damage. Replace worn-out or damaged components promptly to prevent further complications. Regular maintenance schedules help ensure the gearbox operates efficiently and avoids unexpected downtime or costly repairs.

Additional information

| Edited by | Yjx |

|---|