WPWED Worm Gear Reducers/Worm Gearbox

WPWED worm gear reducers, also referred to as double reduction worm gearboxes, are advanced power transmission devices designed for a wide array of industrial applications. These double reduction worm gearboxes incorporate a two-stage reduction system by combining a single-stage worm gearbox with a universal gearbox, enabling them to achieve exceptional torque output and precise speed reduction. With a speed ratio range typically from 1:200 to 1:900, achieved by multiplying the ratios of two single-stage gearboxes (each ranging from 1:10 to 1:60), they offer unparalleled flexibility for operations requiring significant speed control.

WPWED worm gear reducers, also referred to as double reduction worm gearboxes, are advanced power transmission devices designed for a wide array of industrial applications. These double reduction worm gearboxes incorporate a two-stage reduction system by combining a single-stage worm gearbox with a universal gearbox, enabling them to achieve exceptional torque output and precise speed reduction. With a speed ratio range typically from 1:200 to 1:900, achieved by multiplying the ratios of two single-stage gearboxes (each ranging from 1:10 to 1:60), they offer unparalleled flexibility for operations requiring significant speed control.

WPWED worm gear speed reducers are renowned for their compact design, quiet operation, and ability to handle heavy loads efficiently. Their robust construction ensures durability and reliability, making them ideal for demanding industries such as plastics, metallurgy, beverages, mining, construction, and chemicals. These worm reducer gearboxes are particularly valued for their efficiency, long service life, and capability to deliver consistent performance under challenging conditions.

WPWED Worm Gear Reducer Specifications

| Type: | WPWED Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

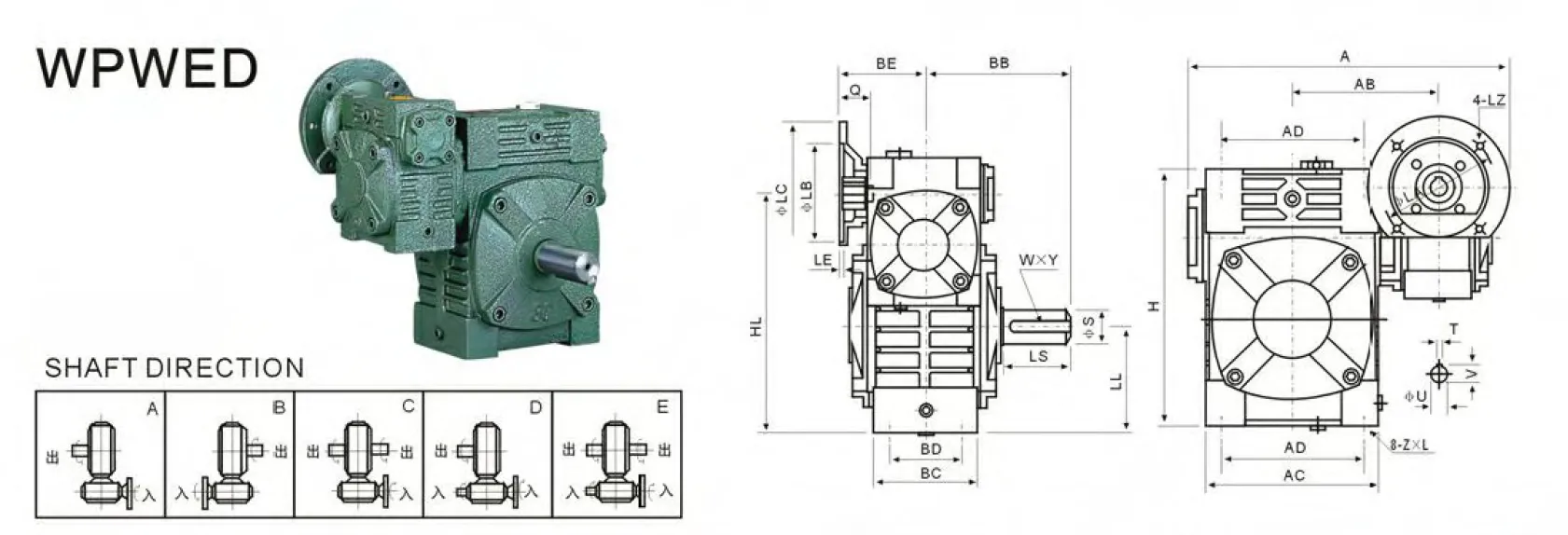

WPWED Worm Gearbox Dimensions

| Model | Power (kW) | Ratio | A | AB | BB | BE | AC | BC | AD | BD | HL | LL | H | ZXL |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 0.12 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 .... | 314 | 153 | 131 | 75 | 152 | 86 | 125 | 65 | 200 | 90 | 215 | M10×25 |

| 50-80 | 0.18 | 314 | 144 | 142 | 83 | 169 | 102 | 140 | 70 | 235 | 105 | 250 | M12×28 | |

| 60-100 | 0.37 | 387 | 175 | 169 | 91 | 216 | 117 | 180 | 90 | 290 | 130 | 310 | M12×30 | |

| 70-120 | 0.37 0.75 | 425 | 193 | 190 | 109 | 256 | 124 | 220 | 100 | 345 | 155 | 370 | M14×32 | |

| 80-135 | 0.75 1.5 | 499 | 226 | 210 | 125 | 296 | 147 | 260 | 110 | 400 | 185 | 425 | M16×35 | |

| 100-155 | 1.5 | 570 | 269 | 252 | 148 | 345 | 185 | 280 | 120 | 458 | 203 | 461 | M16×35 | |

| 120-175 | 2.2 3.0 | 631 | 287 | 255 | 181 | 374 | 192 | 320 | 140 | 518 | 223 | 521 | M16×35 | |

| 135-200 | 3.0 4.0 | 680 | 318 | 319 | 202 | 412 | 230 | 360 | 150 | 580 | 245 | 575 | M20×36 | |

| 155-250 | 5.5 | 815 | 380 | 385 | 247 | 500 | 285 | 420 | 190 | 705 | 300 | 700 | M24×42 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 60 | 28 | 7×4 | 19 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 65 | 32 | 10×4.5 | 28 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 75 | 38 | 10×4.5 | 44 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 75 | 38 | 10×4.5 | 44 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 85 | 45 | 12×4.5 | 66 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 95 | 55 | 16×6 | 101 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 110 | 60 | 18×7 | 139 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 110 | 65 | 18×7 | 196 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 125 | 70 | 20×7.5 | 285 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 155 | 90 | 25×9 | 450 |

WPWED Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWED Worm Gear Speed Reducer Characteristic

- High Torque Output and Efficiency

WPWED worm gear reduction gearboxes deliver exceptional torque through their double-stage reduction design. By combining two single-stage worm gearboxes, they achieve ratios from 1:200 to 1:900, ensuring efficient power transmission for demanding industrial applications requiring precise speed control and high torque. - Compact and Space-Saving Design

These worm drive gearboxes are engineered for compactness, making them ideal for installations with limited space. The integrated single-stage and universal gearbox configuration optimizes size without compromising performance, allowing seamless integration into machinery in industries like plastics, mining, and metallurgy. - Durable and Robust Construction

WPWED worm reducer gearboxes are built with high-quality materials to withstand harsh industrial environments. Their sturdy housing and precision-engineered components ensure long-term reliability, reducing maintenance needs and enhancing operational lifespan in applications such as construction and chemical processing. - Quiet and Smooth Operation

The worm gear design minimizes noise and vibration, providing smooth and quiet performance. This feature is critical for industries like beverage production, where low noise levels improve workplace conditions and ensure consistent operation of sensitive equipment. - Versatile Speed Ratio Range

Offering a wide speed ratio range from 1:200 to 1:900, WPWED worm gear reducers provide flexibility for various applications. The double-stage setup allows precise speed adjustments, catering to diverse operational requirements in sectors such as metallurgy and material handling. - Broad Industrial Applications

WPWED worm gear speed reducers are highly adaptable, serving industries including plastics, mining, beverages, construction, and chemicals. Their ability to handle heavy loads and deliver reliable performance makes them a preferred choice for complex machinery requiring consistent and efficient power transmission.

WPWED Double Reduction Worm Gear Reducer Uses

- Plastics Industry

WPWED double reduction worm gear reducers are widely used in plastic extrusion and molding machines. Their high torque output and precise speed control ensure consistent material processing, enabling efficient production of plastic products with reliable performance and minimal energy waste. - Metallurgy Industry

In metallurgy, worm reducer gearboxes drive heavy machinery like rolling mills and conveyors. Their robust construction and high reduction ratios provide the necessary torque to handle dense metal materials, ensuring smooth operations and durability under demanding conditions of metal processing. - Beverage Industry

These double reduction worm gearboxes support beverage production lines, powering mixers and bottling equipment. Their quiet operation and compact design make them ideal for maintaining hygiene and efficiency, delivering precise speed control for consistent mixing and filling in high-speed production environments. - Mining Industry

WPWED worm gear drive gearboxes are employed in mining equipment such as crushers and conveyors. Their ability to handle heavy loads and provide high torque ensures reliable performance in harsh environments, facilitating efficient material extraction and transport in mining operations. - Construction Industry

In construction, worm reduction gearboxes power machinery like concrete mixers and hoists. Their durability and wide speed ratio range allow precise control and robust performance, supporting heavy-duty tasks while maintaining operational efficiency on construction sites with challenging conditions. - Chemical Industry

WPWED worm gearbox reducers are utilized in chemical processing equipment, such as agitators and pumps. Their corrosion-resistant design and high torque capabilities ensure reliable operation in handling viscous or abrasive materials, maintaining consistent performance in demanding chemical manufacturing processes.

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Mining and Quarrying Industry |

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Construction Industry |

WPWED Double Reduction Worm Gearbox Oil Lubrication

- Enhanced Gear Protection

Oil lubrication in worm reduction gearboxes provides a protective film between the worm and gear surfaces. This minimizes friction and wear, ensuring smooth operation and extending the service life of the gearbox, even under heavy loads and demanding conditions. - Heat Dissipation

Lubricating oil plays a crucial role in dissipating heat generated during operation. Reducing the temperature inside the worm gear drive gearbox, it prevents overheating, protects internal components from damage, and ensures consistent performance, especially in environments with prolonged or high-speed operations. - Corrosion Prevention

High-quality lubricating oil helps protect the internal components of the worm drive reduction gearbox from corrosion. This is particularly important in industries like mining and chemical processing, where exposure to moisture, chemicals, or corrosive substances can degrade the gearbox's performance over time. - Reduction of Noise and Vibration

Proper oil lubrication reduces the noise and vibration generated by the gearbox during operation. This ensures quieter performance, making worm reducer gearboxes suitable for use in industries like food processing and packaging, where minimal noise is a critical requirement. - Improved Efficiency

By reducing friction between moving components, oil lubrication enhances the overall efficiency of the gearbox. Lower resistance during operation translates to reduced energy consumption, making the gearbox more cost-effective and environmentally friendly over its lifespan. - Regular Maintenance and Oil Replacement

To maintain optimal performance, the lubricating oil in double reduction worm gear reducers must be regularly checked and replaced. Proper maintenance ensures the oil retains its viscosity and protective properties, preventing failures and ensuring the gearbox operates efficiently throughout its service life.

Additional information

| Edited by | Yjx |

|---|