WPWE Worm Gear Reducers/Worm Gearbox

WPWE worm gear reducers, also known as double reduction worm gearboxes, are advanced mechanical devices engineered for industrial applications that demand substantial speed reduction and enhanced torque output. These worm gear speed reducers utilize a two-stage reduction system, effectively combining a single-stage worm gearbox with a universal gearbox to deliver improved performance and adaptability. The WPWE double reduction worm gearbox accommodates a wide range of speed ratios, with single-stage configurations offering ratios between 1:10 and 1:60. Meanwhile, the double-stage setup provides significantly higher ratios, spanning from 1:200 to 1:900, by multiplying the individual ratios of two single-stage units.

WPWE worm gear reducers, also known as double reduction worm gearboxes, are advanced mechanical devices engineered for industrial applications that demand substantial speed reduction and enhanced torque output. These worm gear speed reducers utilize a two-stage reduction system, effectively combining a single-stage worm gearbox with a universal gearbox to deliver improved performance and adaptability. The WPWE double reduction worm gearbox accommodates a wide range of speed ratios, with single-stage configurations offering ratios between 1:10 and 1:60. Meanwhile, the double-stage setup provides significantly higher ratios, spanning from 1:200 to 1:900, by multiplying the individual ratios of two single-stage units.

This design ensures not only precise speed regulation but also high torque delivery. Known for their robust construction, compact design, and reliable performance, WPWE worm reducer gearboxes excel in demanding industrial environments. They are widely applied in machinery such as conveyors, mixers, and other equipment across industries like manufacturing, material handling, and heavy-duty operations. Their versatility, durability, and efficiency make them a preferred choice for applications requiring dependable power transmission.

WPWE Worm Gear Reducer Specifications

| Type: | WPWE Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

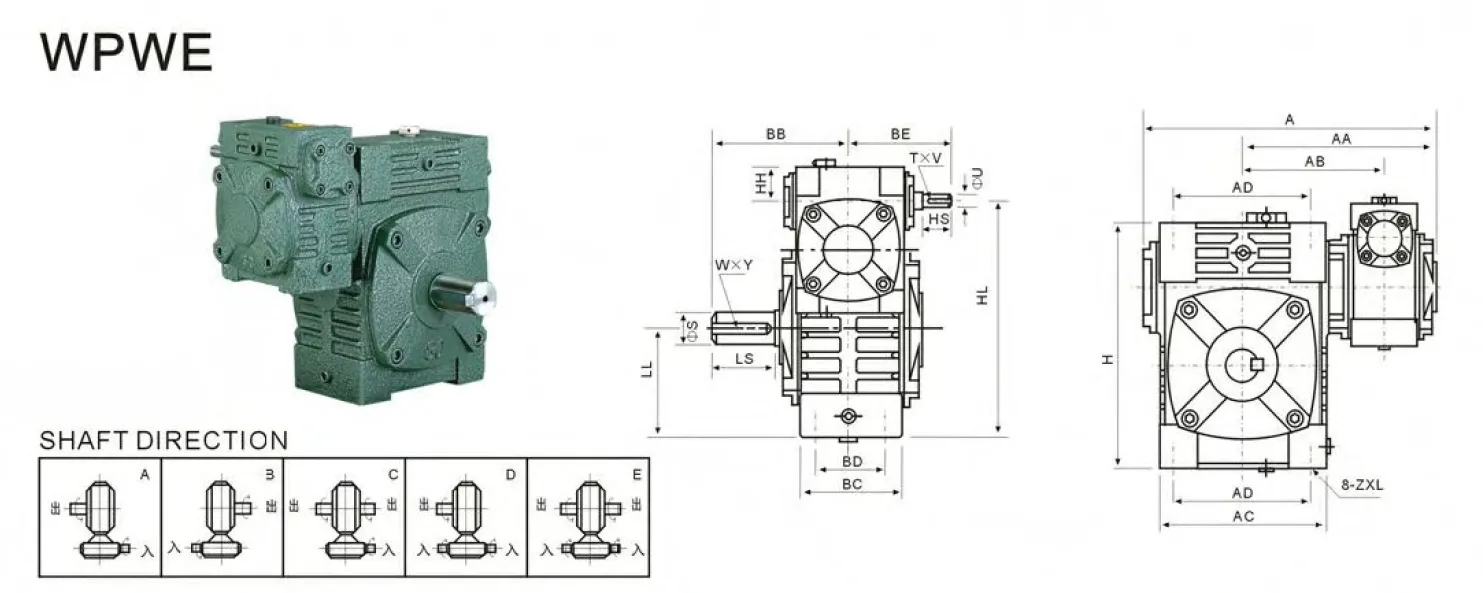

WPWE Worm Gearbox Dimensions

| Model | Ratio | A | AA | AB | BB | BE | AC | BC | AD | BD | HH | HL | LL | H | ZXL |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 .... .... | 286 | 195 | 153 | 131 | 87 | 152 | 86 | 125 | 65 | 35 | 200 | 90 | 215 | M10×25 |

| 50-80 | 297 | 197 | 144 | 142 | 108 | 169 | 102 | 140 | 70 | 35 | 235 | 105 | 250 | M12×28 | |

| 60-100 | 363 | 231 | 175 | 169 | 120 | 216 | 117 | 180 | 90 | 42 | 290 | 130 | 310 | M12×30 | |

| 70-120 | 408 | 256 | 193 | 190 | 140 | 256 | 124 | 220 | 100 | 55 | 345 | 155 | 370 | M14×32 | |

| 80-135 | 471 | 298 | 226 | 210 | 160 | 296 | 147 | 260 | 110 | 65 | 400 | 185 | 425 | M18×35 | |

| 100-155 | 555 | 354 | 269 | 252 | 190 | 345 | 185 | 280 | 120 | 80 | 458 | 203 | 461 | M18×35 | |

| 120-175 | 598 | 379 | 287 | 255 | 219 | 374 | 192 | 320 | 140 | 95 | 518 | 223 | 521 | M18×35 | |

| 135-200 | 662 | 425 | 318 | 319 | 256 | 412 | 230 | 360 | 150 | 105 | 580 | 245 | 575 | M20×36 | |

| 155-250 | 795 | 510 | 380 | 385 | 295 | 500 | 285 | 420 | 190 | 103 | 705 | 300 | 700 | M24×42 |

| Input hole | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 60 | 28 | 7×4 | 19 |

| 30 | 12 | 4×2.5 | 65 | 32 | 10×4.5 | 28 |

| 40 | 15 | 5×3 | 75 | 38 | 10×4.5 | 43 |

| 40 | 18 | 5×3 | 85 | 45 | 12×4.5 | 64 |

| 50 | 22 | 7×4 | 95 | 55 | 16×6 | 99 |

| 50 | 25 | 7×4 | 110 | 60 | 18×7 | 136 |

| 65 | 30 | 7×4 | 110 | 65 | 18×7 | 193 |

| 75 | 35 | 10×5 | 125 | 70 | 20×7.5 | 280 |

| 85 | 40 | 12×5 | 155 | 90 | 25×9 | 442 |

WPWE Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWE Worm Gear Speed Reducer Characteristic

- High Efficiency and Torque Output

WPWE worm gear speed reducers deliver exceptional torque multiplication through a double-stage reduction system. Combining a single-stage worm gearbox with a universal gearbox, they achieve high efficiency, making them ideal for heavy-duty industrial applications requiring precise power transmission. - Wide Speed Ratio Range

These worm drive gearboxes offer a versatile speed ratio range, from 1:10 to 1:60 in single-stage setups and 1:200 to 1:900 in double-stage configurations. This flexibility allows precise speed control, catering to diverse machinery requirements in industries like manufacturing and material handling. - Compact and Robust Design

The worm reducer gearbox is engineered for compactness, enabling easy integration into space-constrained systems. Its durable construction, using high-quality materials, ensures long-term reliability and resistance to wear, even under demanding operational conditions, enhancing overall system performance. - Smooth and Quiet Operation

Designed for minimal noise and vibration, WPWE worm gear reducers provide smooth performance. The precision-engineered worm gears ensure efficient power transfer with reduced friction, making them suitable for applications where quiet operation is critical, such as in food processing or packaging. - Versatile Industrial Applications

WPWE worm gear reduction gearboxes are adaptable to various industries, including conveyors, mixers, and material handling equipment. Their ability to handle varying loads and speeds makes them a preferred choice for applications requiring consistent performance and operational flexibility in industrial settings. - Easy Maintenance and Installation

These worm and wheel gearboxes are designed for straightforward installation and maintenance. Their modular structure allows quick access to components, reducing downtime. The robust design minimizes maintenance needs, ensuring cost-effective operation and prolonged service life in demanding industrial environments.

WPWE Double Reduction Worm Gearbox Application Scenarios

- Conveyor Systems

WPWE double reduction worm gearboxes are widely used in conveyor systems for material handling industries. Their ability to provide precise speed control and high torque ensures smooth and efficient transportation of goods, even under heavy loads, across manufacturing plants and warehouses. - Mixing Equipment

In industries such as food processing, chemical production, and pharmaceuticals, these worm reducer gearboxes are integral to mixing equipment. Their high torque output and accurate speed regulation enable consistent mixing of materials, ensuring uniformity and quality in products requiring precise processing conditions. - Mining Machinery

The rugged construction and high torque performance of WPWE worm gear speed reducers make them suitable for mining applications. They are used in equipment like crushers, conveyors, and loaders, where they endure harsh environments while delivering reliable power transmission for continuous and demanding operations. - Industrial Automation

WPWE worm gearboxes are critical components in industrial automation systems. Their compact size and precise speed control make them ideal for robotic arms, automated assembly lines, and other automated machinery, ensuring high efficiency and accuracy in repetitive and complex tasks. - Agricultural Equipment

In agriculture, these worm gear reduction gearboxes are used in machinery like seeders, harvesters, and irrigation systems. Their efficiency and durability allow them to operate reliably in outdoor environments, handling varying loads and ensuring optimal performance across diverse farming activities. - Cranes and Hoists

WPWE worm reduction gearboxes are crucial for cranes and hoists used in construction and logistics. Their ability to deliver high torque with precise speed adjustment ensures safe and efficient lifting, lowering, and positioning of heavy materials, even in challenging working conditions.

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Food and Beverage Industry |

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Construction Industry |

Double Reduction Worm Gearbox Vs. Single Reduction Worm Gearbox

Double reduction worm gearboxes and single reduction worm gearboxes are both widely used in industrial applications, but they differ significantly in design, performance, and application suitability. Understanding these differences is essential for selecting the right gear reducer for specific requirements.

A single reduction worm gearbox features a single-stage reduction system where the input shaft drives the worm, which in turn rotates the worm wheel. This configuration provides a speed ratio typically ranging from 5:1 to 60:1, depending on the gear set. Single reduction gearboxes are compact and efficient for applications requiring moderate speed reduction and torque multiplication. They are widely used in light-to-medium-duty applications, such as conveyor belts, small machinery, and simple lifting mechanisms, where compact size and straightforward operation are key considerations.

In contrast, a double reduction worm gearbox incorporates two reduction stages. The first stage consists of a worm gear set, and the output from this is fed into a second worm gear set for further reduction. This design enables much higher speed ratios, ranging from 200:1 to 900:1, making it ideal for applications requiring significant speed reduction and high torque output. Double reduction gearboxes are larger in size compared to single reduction models but provide greater performance and adaptability. They are commonly used in heavy-duty applications like mining equipment, industrial mixers, and cranes, where precise speed control and the ability to handle high torque loads are essential.

While single reduction gearboxes are simpler, cost-effective, and more compact, double reduction gearboxes excel in situations requiring enhanced performance, higher torque, and extreme speed reduction. The choice depends on the specific operational needs, load requirements, and space constraints of the application.

|  |

| Double Reduction Worm Gearbox | Single Reduction Worm Gearbox |

Additional information

| Edited by | Yjx |

|---|