WPWEDKO Worm Gear Reducers/Worm Gearbox

WPWEDKO worm gear reducers, also known as double reduction worm gearboxes, are advanced, compact, and highly efficient systems designed for a wide range of industrial applications. These worm reduction gearboxes combine a single-stage worm gearbox with a universal gearbox, delivering enhanced performance, flexibility, and high torque output in a space-saving design. WPWEDKO worm gear speed reducers are widely used in industries such as plastics, metallurgy, beverage production, mining, lifting and transportation, and chemical construction.

WPWEDKO worm gear reducers, also known as double reduction worm gearboxes, are advanced, compact, and highly efficient systems designed for a wide range of industrial applications. These worm reduction gearboxes combine a single-stage worm gearbox with a universal gearbox, delivering enhanced performance, flexibility, and high torque output in a space-saving design. The single-stage configuration offers speed ratios from 1:10 to 1:60, while the double-stage setup achieves significantly higher ratios, ranging from 1:200 to 1:900, by multiplying the ratios of two single-stage gearboxes.

This makes them ideal for applications requiring substantial speed reduction and precise control. WPWEDKO worm gear speed reducers are widely used in industries such as plastics, metallurgy, beverage production, mining, lifting and transportation, and chemical construction. Their robust construction ensures durability, low maintenance, and reliable operation under demanding conditions, making them a preferred choice for heavy-duty industrial tasks.

WPWEDKO Worm Gear Reducer Specifications

| Type: | WPWEDKO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

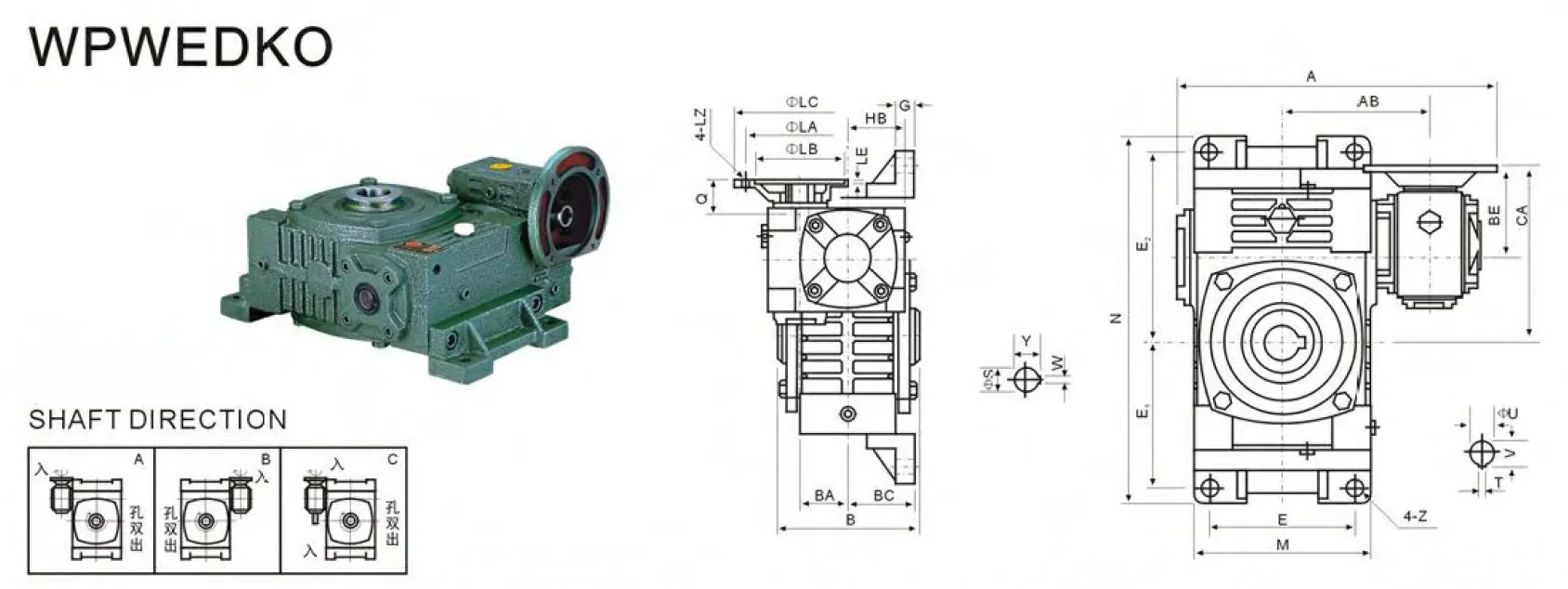

WPWEDKO Worm Gearbox Dimensions

| Model | Power (kW) | Ratio | A | AB | B | BA | BC | BE | HB | CA | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 0.12 | 1/200 1/300 1/400 1/500 1/600 1/800 .... | 314 | 153 | 130 | 40 | 65 | 75 | 50 | 145 | 152 | 305 | 120 | 120 | 155 | 20 | 15 |

| 50-80 | 0.18 | 314 | 144 | 150 | 50 | 70 | 83 | 65 | 163 | 174 | 350 | 140 | 140 | 180 | 20 | 15 | |

| 60-100 | 0.37 | 387 | 175 | 160 | 60 | 90 | 91 | 75 | 191 | 224 | 410 | 190 | 165 | 215 | 22 | 15 | |

| 70-120 | 0.37 0.75 | 425 | 193 | 175 | 70 | 100 | 109 | 90 | 229 | 264 | 494 | 220 | 195 | 255 | 25 | 18 | |

| 80-135 | 0.75 1.5 | 499 | 226 | 210 | 80 | 110 | 125 | 105 | 260 | 304 | 559 | 260 | 230 | 285 | 30 | 18 | |

| 100-155 | 1.5 | 570 | 269 | 256 | 100 | 140 | 148 | 130 | 303 | 345 | 605 | 290 | 250 | 305 | 35 | 21 | |

| 120-175 | 2.2 3.0 | 631 | 287 | 282 | 120 | 150 | 181 | 155 | 356 | 374 | 675 | 320 | 273 | 348 | 40 | 21 | |

| 135-200 | 3.0 4.0 | 680 | 318 | 320 | 135 | 175 | 202 | 185 | 402 | 424 | 749 | 370 | 305 | 390 | 40 | 24 | |

| 155-250 | 5.5 | 815 | 380 | 400 | 155 | 200 | 247 | 203 | 497 | 510 | 920 | 440 | 375 | 475 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 30 | 35 | 8×33.3 | 20 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 35 | 35 | 10×38.3 | 31 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 40 | 40 | 12×43.3 | 48 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 40 | 40 | 12×43.3 | 48 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 45 | 45 | 14×48.8 | 71 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 60 | 60 | 18×64.4 | 107 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 70 | 70 | 20×74.9 | 166 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 60 | 65 | 22×85.4 | 211 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 70 | 22×90.4 | 307 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 90 | 28×116.4 | 484 |

WPWEDKO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWEDKO Double Reduction Worm Gearbox Parts

- Worm Shaft

The worm shaft is a critical component made from high-strength steel, designed to transmit power efficiently. It features a precisely machined helical thread that engages with the worm wheel, ensuring smooth operation and high torque output in demanding industrial applications. - Worm Wheel

Constructed from durable bronze or alloy, the worm wheel meshes with the worm shaft to achieve significant speed reduction. Its robust design ensures longevity and resistance to wear, making it suitable for heavy-duty tasks in industries like metallurgy and mining. - Input Shaft

The input shaft connects the worm reducer gearbox to the power source, such as a motor. Made from hardened steel, it ensures reliable power transmission. Its precise alignment enhances efficiency and minimizes energy loss in applications like chemical construction and beverage production. - Output Shaft

The output shaft delivers the reduced speed and increased torque to the driven equipment. Crafted from high-quality materials, it withstands heavy loads and ensures consistent performance in industries such as plastics, transportation, and lifting, where reliability is paramount. - Gearbox Housing

The housing, typically made of cast iron or aluminum, encases all components, providing structural integrity. Its compact yet robust design protects internal parts from dust and debris, ensuring durability in harsh environments like mining and metallurgical operations. - Bearings

High-precision bearings support the worm shaft and wheel, reducing friction and enhancing efficiency. These bearings ensure smooth rotation and extend the worm drive gearbox’s lifespan, making them vital for continuous operation in industries such as chemical processing and beverage manufacturing. - Seals and Gaskets

Seals and gaskets prevent lubricant leakage and protect against contaminants. Made from high-quality materials, they ensure the worm reduction gearbox operates efficiently in dusty or wet conditions, such as those found in mining and transportation applications, maintaining long-term reliability.

WPWEDKO Worm Drive Reduction Gearbox Uses

- Plastics Industry

In the plastics industry, WPWEDKO worm drive reduction gearboxes are used in extrusion machines, mixers, and molding equipment. Their ability to provide precise speed reduction and high torque ensures efficient operation during material processing, shaping, and production of high-quality plastic components. - Metallurgy and Metal Processing

These worm gear reducerss are widely applied in metallurgy for tasks like rolling, forging, and cutting. Their robust design and high torque output make them ideal for heavy-duty applications, ensuring reliable performance when handling high loads and extreme operating conditions in metal processing plants. - Mining and Quarrying

WPWEDKO worm gear speed reducers are essential in mining equipment such as conveyors, crushers, and screening systems. Their exceptional durability and high reduction ratios enable them to handle the harsh environments and heavy loads common in mining and quarrying operations with minimal maintenance. - Lifting and Transportation Equipment

In lifting and transportation systems like cranes, hoists, and conveyors, these worm reducer gearboxes ensure smooth and precise speed control. Their ability to handle high torque makes them suitable for moving heavy loads safely and efficiently in industrial and construction settings. - Beverage and Food Processing

WPWEDKO worm and wheel gearboxes are used in bottling lines, mixers, and packaging machines in the beverage and food industries. Their compact design, reliability, and ability to provide precise speed control make them ideal for maintaining consistent quality and efficiency in production processes. - Chemical and Construction Industries

In chemical plants and construction machinery, these worm drive gearboxes are employed in mixers, pumps, and heavy-duty equipment. Their ability to operate under demanding conditions, combined with their high torque output, ensures reliable performance in environments that require rugged and efficient power transmission.

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Mining and Quarrying Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Food and Beverage Industry |

WPWEDKO Worm Gear Speed Reducer Installation Steps

- Preparation and Inspection: Before installation, verify that the double reduction worm gearbox specifications match the application requirements. Check all components for damage and ensure the work area is clean. Gather necessary tools, including wrenches, alignment tools, and mounting hardware, to ensure a smooth installation process in industrial settings.

- Mounting Surface Setup: Prepare a stable, level mounting surface to support the worm drive gearbox. Ensure the foundation is rigid to prevent vibrations. Clean the surface to remove debris and align the gearbox mounting holes with the base to guarantee secure attachment and optimal performance.

- Gearbox Alignment: Align the worm reduction gearbox with the driven equipment and motor. Use precision alignment tools to ensure the input and output shafts are perfectly aligned. Proper alignment reduces wear, enhances efficiency, and prevents premature failure in applications like metallurgy or plastics processing.

- Securing the Gearbox: Fasten the worm gearbox reducer to the mounting surface using appropriate bolts and torque specifications. Tighten bolts evenly in a cross pattern to ensure uniform pressure. This step ensures stability during operation, especially in high-torque applications like mining or lifting systems.

- Connecting Input and Output Shafts: Connect the input shaft to the motor and the output shaft to the driven equipment using suitable couplings. Ensure tight connections to prevent slippage. Verify alignment again after connection to maintain efficiency and reduce stress on the gearbox components.

- Lubrication and Testing: Fill the worm gear reduction gearbox with the recommended lubricant to the specified level. Check for leaks and ensure proper sealing. Run the gearbox under no-load conditions to verify smooth operation, checking for unusual noises or vibrations before full deployment in industrial tasks.

Additional information

| Edited by | Yjx |

|---|