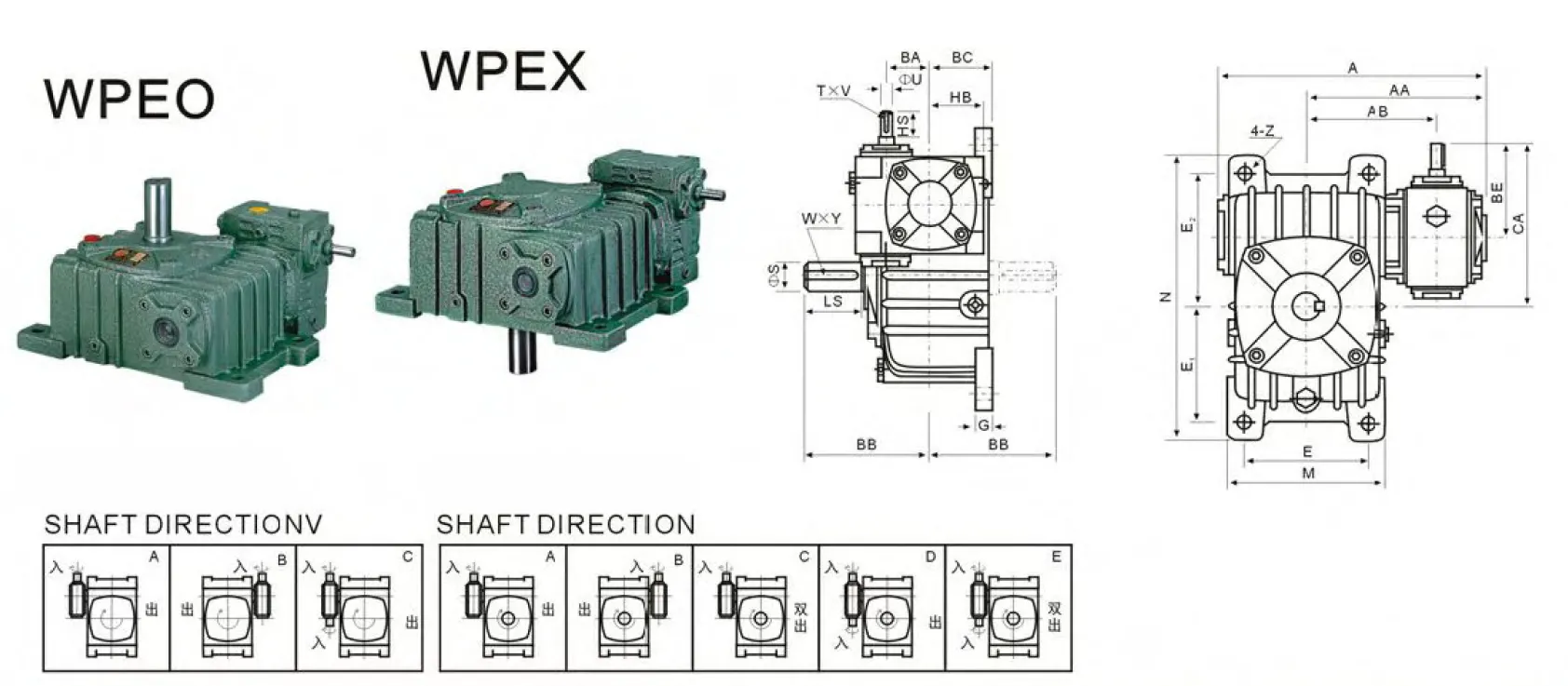

WPEX Worm Gear Reducers/Worm Gearbox

WPEX worm gear reducers, also known as double reduction worm gearboxes, are advanced power transmission devices renowned for their efficiency, compact design, and versatility across a wide range of industrial applications. These worm reduction gearboxes incorporate a distinctive double-stage configuration by combining a single-stage worm gearbox with a universal gearbox. This design delivers exceptional torque output, flexibility, and precise speed control. WPEX worm gear speed reducers excel in demanding industries like plastics, metallurgy, mining, beverages, chemical construction, and lifting/transportation.

WPEX worm gear reducers, also known as double reduction worm gearboxes, are advanced power transmission devices renowned for their efficiency, compact design, and versatility across a wide range of industrial applications. These worm reduction gearboxes incorporate a distinctive double-stage configuration by combining a single-stage worm gearbox with a universal gearbox. This design delivers exceptional torque output, flexibility, and precise speed control.

The WPEX double reduction worm gearbox is particularly suited for applications requiring substantial reduction ratios, with single-stage setups offering ratios from 1:10 to 1:60 and double-stage configurations achieving impressive ratios ranging from 1:200 to 1:900 by multiplying the ratios of two single-stage systems. Engineered for smooth operation, durability, and energy efficiency, WPEX worm gear speed reducers excel in demanding industries like plastics, metallurgy, mining, beverages, chemical construction, and lifting/transportation.

WPEX Worm Gear Reducer Specifications

| Type: | WPEX Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

WPEX Worm Gearbox Dimensions

| Model | Ratio | A | AA | AB | BA | BB | BC | BE | HB | CA | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 1/200 1/300 1/400 1/400 1/500 1/600 1/800 1/900 .... | 286 | 195 | 153 | 40 | 131 | 65 | 87 | 50 | 157 | 195 | 295 | 120 | 120 | 135 | 20 | 15 |

| 50-80 | 297 | 197 | 144 | 50 | 142 | 70 | 108 | 65 | 188 | 175 | 320 | 140 | 130 | 150 | 20 | 15 | |

| 60-100 | 363 | 231 | 175 | 60 | 169 | 90 | 120 | 75 | 222 | 224 | 375 | 190 | 155 | 180 | 25 | 15 | |

| 70-120 | 408 | 256 | 193 | 70 | 190 | 100 | 140 | 90 | 260 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 80-135 | 471 | 298 | 226 | 80 | 210 | 110 | 160 | 105 | 295 | 306 | 495 | 260 | 210 | 235 | 30 | 18 | |

| 100-155 | 555 | 354 | 269 | 100 | 252 | 140 | 190 | 130 | 345 | 350 | 590 | 290 | 245 | 295 | 35 | 21 | |

| 120-175 | 598 | 379 | 287 | 120 | 255 | 150 | 219 | 155 | 394 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 135-200 | 662 | 425 | 318 | 135 | 319 | 175 | 256 | 185 | 456 | 440 | 710 | 370 | 290 | 360 | 40 | 24 | |

| 155-250 | 795 | 510 | 380 | 155 | 385 | 200 | 295 | 203 | 545 | 510 | 860 | 440 | 350 | 440 | 45 | 28 |

| Input shaft | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 60 | 28 | 8×4 | 19 |

| 30 | 12 | 4×2.5 | 65 | 32 | 10×4.5 | 27 |

| 40 | 15 | 5×3 | 75 | 38 | 10×4.5 | 44 |

| 40 | 18 | 5×3 | 85 | 45 | 12×4.5 | 63 |

| 50 | 22 | 7×4 | 95 | 55 | 16×6 | 96 |

| 50 | 25 | 7×4 | 110 | 60 | 18×7 | 149 |

| 65 | 30 | 7×4 | 110 | 65 | 18×7 | 191 |

| 75 | 35 | 10×4.5 | 125 | 70 | 20×7.5 | 278 |

| 85 | 40 | 12×5 | 155 | 90 | 25×9 | 442 |

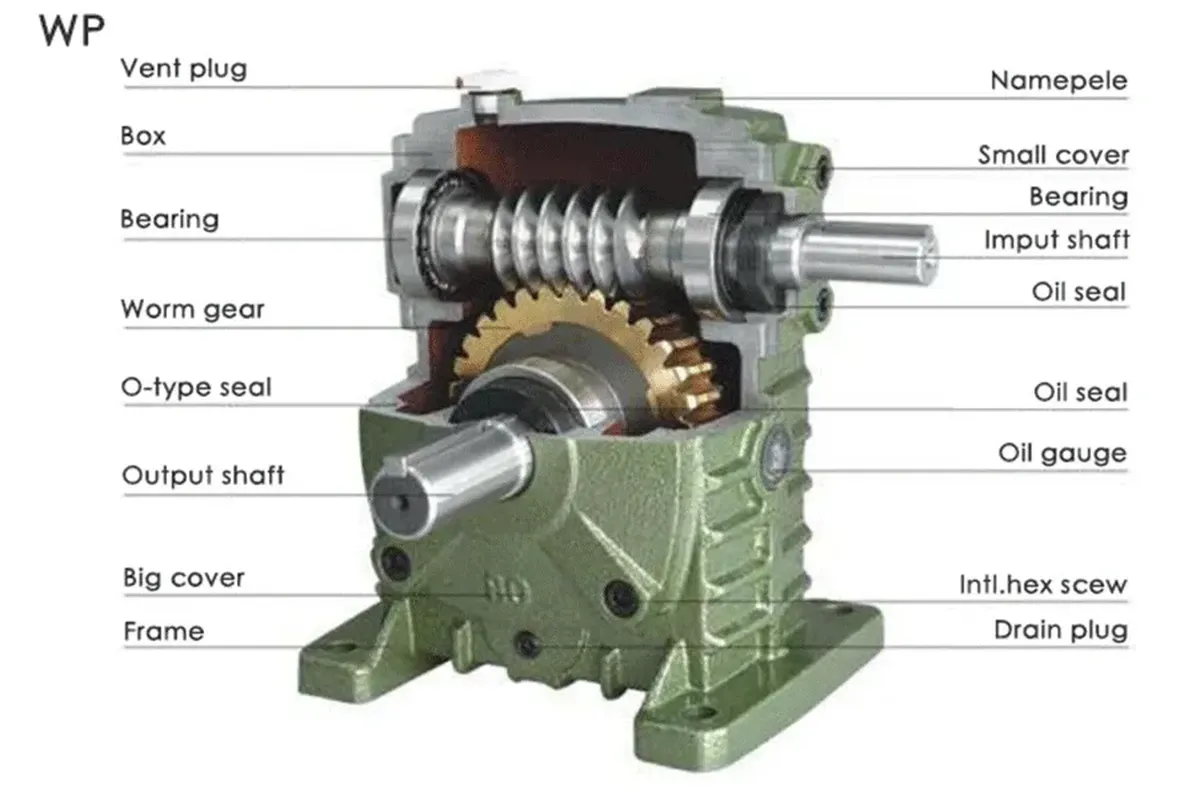

WPEX Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEX Double Reduction Worm Drive Gearbox Benefits

1. High Reduction Ratios

The WPEX double reduction worm gearbox design offers exceptionally high reduction ratios, ranging from 1:200 to 1:900. This capability ensures precise control over output speeds, making it ideal for applications requiring significant torque and controlled motion in demanding industrial environments.

2. Compact and Space-Saving Design

These worm reducer gearboxes are engineered with a compact structure that combines two single-stage worm gearboxes into one unit. This space-efficient design is perfect for installations with limited room, providing high performance without compromising on durability or efficiency.

3. Enhanced Durability and Robust Construction

Built from high-quality materials and designed for heavy-duty use, the WPEX worm drive gearbox provides exceptional durability. Its robust construction ensures reliable performance under harsh conditions, such as extreme temperatures, heavy loads, and continuous operation.

4. Energy Efficiency and Smooth Operation

The worm gear reducers ensure minimal energy loss during operation due to their advanced design and precision engineering. This results in smooth, vibration-free performance, reducing wear and tear while maintaining energy efficiency, even under high torque or prolonged use.

5. Versatility Across Industrial Applications

WPEX worm gear speed reducers are highly versatile and suitable for various industries, including plastics, metallurgy, mining, beverages, and chemical construction. Their ability to function across such diverse applications makes them an excellent choice for businesses seeking reliable and flexible power transmission solutions.

6. Customizable and Adaptable Configurations

The WPEX worm gear reduction gearboxes support customizable configurations to meet specific application needs. With options for varied reduction ratios, mounting arrangements, and output torque levels, these gearboxes can be tailored to provide optimal performance for unique operational requirements.

WPEX Worm Reducer Gearbox Applications

1. Plastics Industry

WPEX worm reducer gearboxes are extensively used in plastic extrusion and molding machinery. Their precise speed control and high torque output ensure consistent operation, enabling the production of high-quality plastic products while maintaining efficiency in processes like extrusion, injection molding, and blow molding.

2. Metallurgy and Steel Manufacturing

In the metallurgy industry, these double reduction worm gearboxes play a critical role in equipment such as rolling mills, conveyors, and steel processing machines. Their ability to handle heavy loads, operate smoothly, and provide precise torque control ensures reliable operation in high-stress environments.

3. Mining and Material Handling

WPEX worm gear speed reducers are ideal for mining applications, including crushers, conveyors, and hoists. Their robust construction and high reduction ratios allow them to manage the heavy loads and harsh conditions found in mining operations, ensuring durability and consistent performance.

4. Beverage and Food Processing

These worm drive gearboxes are utilized in food and beverage machinery, such as bottling lines and mixing systems. Their compact design, smooth operation, and energy efficiency make them well-suited for applications that demand cleanliness, reliability, and precise speed adjustments in production processes.

5. Chemical and Construction Industries

In chemical plants and construction equipment, WPEX double reduction worm gear reducers are used in mixers, agitators, and lifting systems. Their resistance to harsh chemicals, ability to handle heavy-duty applications, and adaptability to varied environments make them indispensable in these fields.

6. Lifting and Transportation Equipment

Worm reduction gearboxes are commonly found in elevators, cranes, and conveyor systems. Their high torque output, compact size, and reliable performance under continuous operation ensure safe and efficient handling of goods in warehouses, factories, and large-scale logistics operations.

|  |

| Worm Gearbox for Plastic and Rubber Machinery | Worm Gearbox for Metallurgy Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Mining and Quarrying Industry |

WPEX Worm Gear Reducer Components

Worm Shaft

The worm shaft is a precision-engineered component that initiates power transmission in the worm gear reduction gearbox. Made from hardened steel, it features a threaded profile that engages the worm wheel, ensuring efficient torque transfer and smooth operation in industrial applications.

Worm Wheel

The worm wheel, typically crafted from bronze or alloy, meshes with the worm shaft to achieve significant speed reduction. Its robust design ensures high torque output and durability, making it essential for reliable performance in heavy-duty machinery and equipment.

Input Shaft

The input shaft connects the worm gear drive gearbox to the driving motor or power source. Designed for high strength and precise alignment, it efficiently transmits rotational energy to the worm shaft, enabling consistent operation in various industrial systems and setups.

Output Shaft

The output shaft delivers the reduced speed and increased torque to the driven machinery. Constructed from durable materials, it ensures reliable power transmission, supporting applications like conveyors and mixers that require precise control and robust performance under load.

Gearbox Housing

The gearbox housing encases all internal components, providing structural integrity and protection. Made from cast iron or aluminum, it ensures alignment, dissipates heat, and shields against environmental factors, enhancing the longevity of the worm gear reducer in harsh conditions.

Bearings

High-quality bearings support the worm shaft and output shaft, reducing friction and wear. Their precision design ensures smooth rotation and load distribution, contributing to the efficiency and extended service life of the worm gearbox in demanding industrial environments.

Seals and Gaskets

Seals and gaskets prevent lubricant leakage and protect against dust and contaminants. These components ensure the internal environment remains clean and lubricated, maintaining optimal performance and reducing maintenance needs for the worm gear speed reducer in various applications.

Additional information

| Edited by | Yjx |

|---|