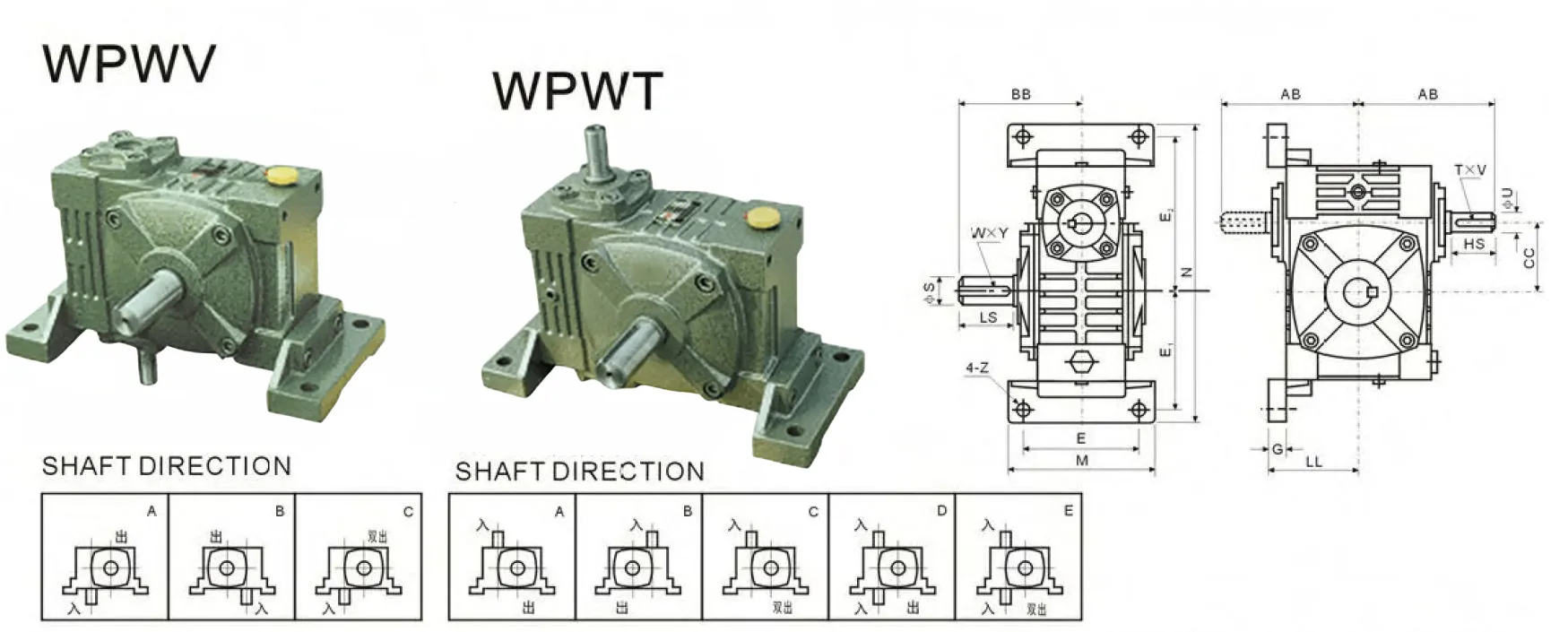

WPWT Worm Gear Reducers/Worm Gearbox

WPWT worm gear reducers, part of the renowned WP series worm gearboxes, are highly efficient and compact mechanical devices engineered for reliable power transmission in various industrial applications. These reducers employ a worm (a screw-like gear) and a worm wheel (a spur-like gear) to deliver substantial speed reduction and torque multiplication, with single-stage ratios typically ranging from 5:1 to 60:1, or up to 10,000:1 in double reduction setups. The WPWT worm gearbox stands out with its robust design, featuring a durable cast iron housing, a hardened 45# steel worm for superior strength, and a tin bronze worm wheel to enhance wear resistance.

WPWT worm gear reducers, part of the renowned WP series worm gearboxes, are highly efficient and compact mechanical devices engineered for reliable power transmission in various industrial applications. These reducers employ a worm (a screw-like gear) and a worm wheel (a spur-like gear) to deliver substantial speed reduction and torque multiplication, with single-stage ratios typically ranging from 5:1 to 60:1, or up to 10,000:1 in double reduction setups. The WPWT worm gearbox stands out with its robust design, featuring a durable cast iron housing, a hardened 45# steel worm for superior strength, and a tin bronze worm wheel to enhance wear resistance.

Designed for maximum versatility, they support multiple mounting options (horizontal or vertical) and configurations, including solid or hollow output shafts, as well as IEC B5/B14 motor flanges for seamless integration. These worm gear speed reducers are prized for their low noise, minimal vibration, and self-locking ability at higher ratios (5:1 to 60:1), reducing the need for additional braking systems. Ideal for use in compact spaces, they are commonly utilized in industries such as manufacturing, elevators, mining, and conveyor systems, where precision and durability are critical.

WPWT Worm Gear Reducer Specifications

| Type: | WPWT Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWT Worm Gearbox Dimensions

| Model | Ratio | AB | BB | CC | LL | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 87 | 74 | 40 | 63 | 90 | 187 | 70 | 72 | 97 | 12 | 10 |

| 50 | 108 | 97 | 50 | 70 | 120 | 226 | 95 | 90 | 110 | 14 | 12 | |

| 60 | 120 | 112 | 60 | 80 | 130 | 257 | 105 | 102 | 129 | 15 | 12 | |

| 70 | 140 | 131 | 70 | 95 | 150 | 305 | 115 | 120 | 155 | 20 | 15 | |

| 80 | 160 | 142 | 80 | 105 | 170 | 350 | 135 | 140 | 180 | 20 | 15 | |

| 100 | 190 | 169 | 100 | 135 | 190 | 410 | 155 | 165 | 215 | 22 | 15 | |

| 120 | 219 | 190 | 120 | 160 | 230 | 494 | 180 | 195 | 255 | 25 | 18 | |

| 135 | 249 | 210 | 135 | 185 | 250 | 559 | 200 | 230 | 285 | 30 | 18 | |

| 155 | 295 | 252 | 155 | 220 | 275 | 605 | 220 | 250 | 305 | 35 | 21 | |

| 175 | 314 | 255 | 175 | 240 | 310 | 675 | 250 | 273 | 348 | 40 | 21 | |

| 200 | 342 | 319 | 200 | 280 | 360 | 749 | 290 | 305 | 390 | 40 | 24 | |

| 250 | 420 | 385 | 250 | 315 | 460 | 920 | 380 | 375 | 475 | 45 | 28 |

| Input shaft | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×V | (kg) |

| 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 5 |

| 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 8 |

| 40 | 15 | 5×3 | 50 | 22 | 7×4 | 11 |

| 40 | 18 | 5×3 | 60 | 28 | 7×4 | 15.5 |

| 50 | 22 | 7×4 | 65 | 32 | 10×4.5 | 24 |

| 50 | 25 | 7×4 | 75 | 38 | 10×4.5 | 38 |

| 65 | 30 | 7×4 | 85 | 45 | 12×4.5 | 56 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 84 |

| 85 | 40 | 12×5 | 110 | 60 | 18×7 | 129 |

| 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 157 |

| 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 224 |

| 110 | 60 | 18×7 | 155 | 90 | 25×9 | 374 |

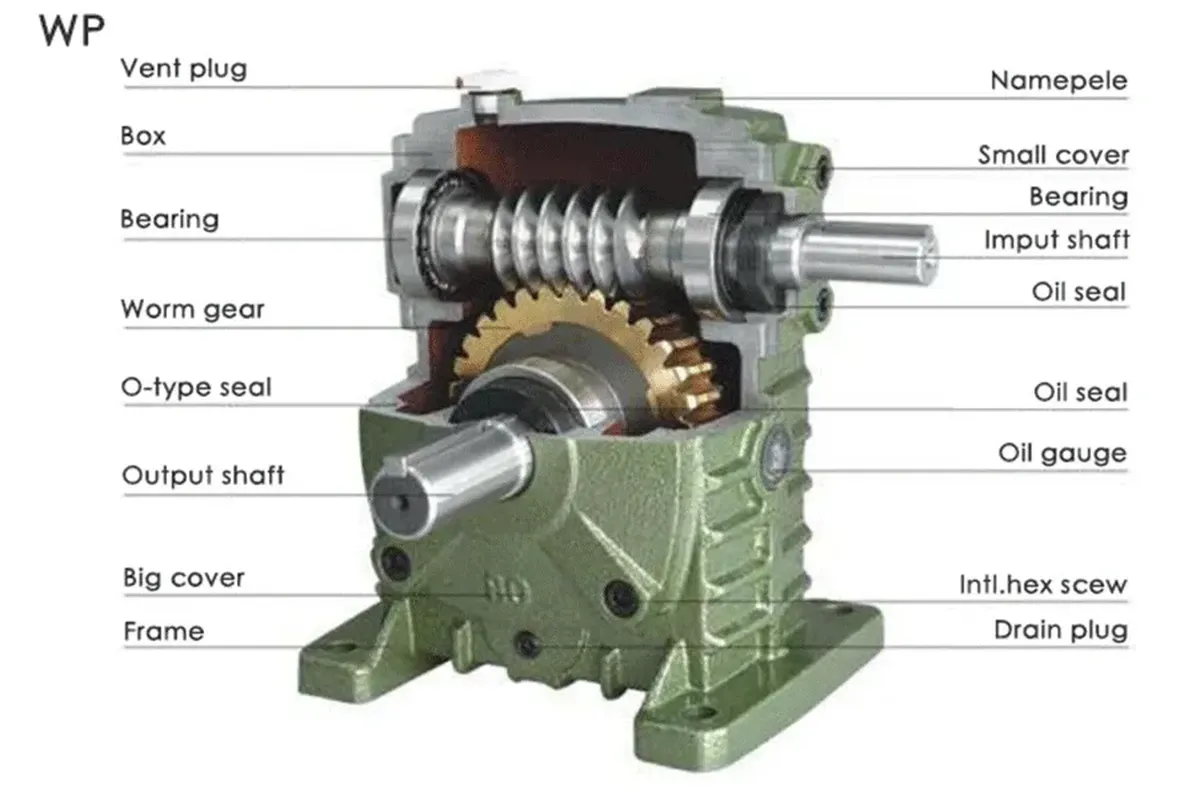

WPWT Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWT Worm Gear Speed Reducer Parts

- Worm Shaft

The worm shaft is a screw-like component made from hardened 45# steel. It engages the worm wheel to transmit power and achieve high gear reduction ratios. Its precise machining ensures smooth operation, durability, and efficient torque transfer in compact industrial applications. - Worm Gear

Constructed from tin bronze, the worm gear is a spur-like gear that meshes with the worm shaft. Its robust material resists wear and corrosion, ensuring longevity. This component enables high torque output and smooth power transmission in demanding mechanical systems. - Housing

The cast iron housing provides structural integrity and durability. It encases all internal components, protecting them from environmental factors. Its rigid design minimizes vibration and noise, while offering versatile mounting options for horizontal or vertical installations in various industrial setups. - Output Shaft

Available in solid or hollow configurations, the output shaft transfers torque to driven equipment. Made from high-strength steel, it ensures reliable power delivery. Its design supports customization, accommodating different coupling methods for seamless integration into diverse machinery applications. - Input Flange

The input flange, typically conforming to IEC B5 or B14 standards, facilitates easy motor connection. Crafted from durable materials, it ensures secure alignment and efficient power transfer. This component enhances the reducer’s compatibility with various motor types in industrial systems. - Bearings

High-quality bearings support the worm shaft and worm wheel, reducing friction and wear. They ensure smooth rotation and precise alignment, enhancing efficiency and extending service life. These components are critical for maintaining performance under high loads in continuous operations. - Seals

Oil seals prevent lubricant leakage and protect internal components from contaminants. Made from durable rubber or synthetic materials, they ensure reliable sealing under varying temperatures and pressures. This maintains optimal lubrication, enhancing the reducer’s efficiency and longevity in harsh environments.

WPWT Worm Gearbox Application Industry

Additional information

| Edited by | Yjx |

|---|