WPWKT Worm Gear Reducers/Worm Gearbox

WPWKT worm gear reducers, part of the WP series worm gearboxes, are highly efficient mechanical devices engineered for industrial transmission applications. These reducers are designed with a compact and durable structure, making them ideal for use in space-constrained environments. The worm gear consists of a screw-like worm made from heat-treated 45# high-quality steel, ensuring exceptional strength and wear resistance, while the worm wheel is crafted from tin bronze to deliver excellent durability and high bearing capacity.

WPWKT worm gear reducers, part of the WP series worm gearboxes, are highly efficient mechanical devices engineered for industrial transmission applications. These reducers are designed with a compact and durable structure, making them ideal for use in space-constrained environments. The worm gear consists of a screw-like worm made from heat-treated 45# high-quality steel, ensuring exceptional strength and wear resistance, while the worm wheel is crafted from tin bronze to deliver excellent durability and high bearing capacity.

The WPWKT worm gearboxes feature an axial worm reducer configuration, with a shaft hole output and an input shaft located on the upper side, allowing for versatile mounting options. Known for their stability, these reducers provide smooth and consistent transmission with minimal vibration, noise, and impact. They achieve large reduction ratios and high torque multiplication, making them suitable for demanding applications. Commonly used in industries such as plastics, metallurgy, mining, and chemical construction, WPWKT worm gear speed reducers are valued for their reliable speed reduction and torque enhancement capabilities.

WPWKT Worm Gear Reducer Specifications

| Type: | WPWKT Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

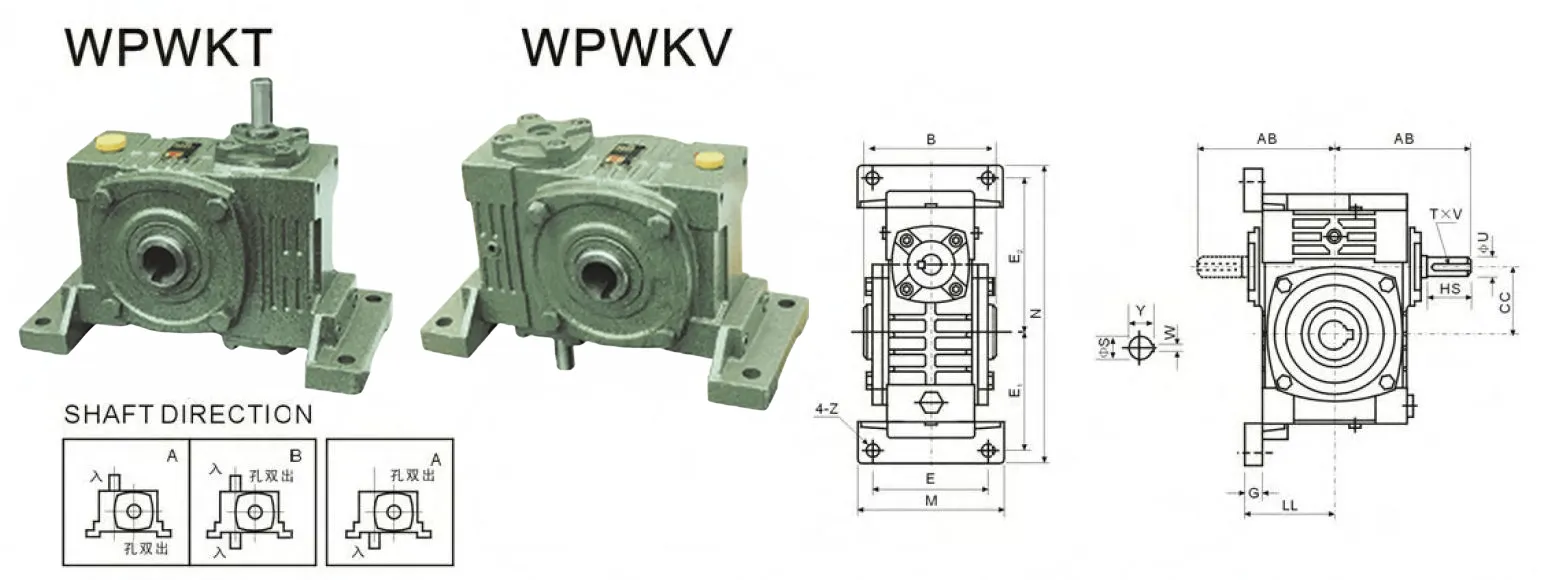

WPWKT Worm Gearbox Dimensions

| Model | Ratio | AB | B | CC | LL | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 87 | 85 | 40 | 63 | 90 | 187 | 70 | 72 | 97 | 12 | 10 |

| 50 | 108 | 105 | 50 | 70 | 120 | 226 | 95 | 90 | 110 | 14 | 12 | |

| 60 | 120 | 110 | 60 | 80 | 130 | 257 | 105 | 102 | 129 | 15 | 12 | |

| 70 | 140 | 130 | 70 | 95 | 150 | 305 | 115 | 120 | 155 | 20 | 15 | |

| 80 | 160 | 150 | 80 | 105 | 170 | 350 | 135 | 140 | 180 | 20 | 15 | |

| 100 | 190 | 160 | 100 | 135 | 190 | 410 | 155 | 165 | 215 | 22 | 15 | |

| 120 | 219 | 175 | 120 | 160 | 230 | 494 | 180 | 195 | 255 | 25 | 18 | |

| 135 | 249 | 210 | 135 | 185 | 250 | 559 | 200 | 230 | 285 | 30 | 18 | |

| 155 | 295 | 256 | 155 | 220 | 275 | 605 | 220 | 250 | 305 | 35 | 21 | |

| 175 | 314 | 282 | 175 | 240 | 310 | 675 | 250 | 273 | 348 | 40 | 21 | |

| 200 | 342 | 320 | 200 | 280 | 360 | 749 | 290 | 305 | 390 | 40 | 24 | |

| 250 | 420 | 400 | 250 | 315 | 460 | 920 | 380 | 375 | 475 | 45 | 28 |

| Input shaft | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×V | (kg) |

| 25 | 12 | 4×2.5 | 16 | 6×18.8 | 5 |

| 30 | 12 | 4×2.5 | 20 | 6×22.8 | 8 |

| 40 | 15 | 5×3 | 25 | 8×28.3 | 11 |

| 40 | 18 | 5×3 | 30 | 8×33.3 | 15.5 |

| 50 | 22 | 7×4 | 35 | 10×38.3 | 24 |

| 50 | 25 | 7×4 | 40 | 12×43.3 | 38 |

| 65 | 30 | 7×4 | 45 | 14×48.8 | 56 |

| 75 | 35 | 10×4.5 | 60 | 18×64.4 | 84 |

| 85 | 40 | 12×5.5 | 70 | 20×74.9 | 129 |

| 85 | 45 | 14×5.5 | 80 | 22×85.4 | 157 |

| 95 | 50 | 14×5.5 | 85 | 22×90.4 | 224 |

| 110 | 60 | 18×7 | 110 | 28×116.4 | 374 |

WPWKT Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWKT Worm Reducer Gearbox Advantages

- High Efficiency and Torque Output

WPWKT worm gear reducers deliver exceptional torque multiplication with reduction ratios up to 60:1. Their worm and worm wheel design, using high-quality steel and tin bronze, ensures efficient power transmission, making them ideal for heavy-duty industrial applications requiring robust performance. - Compact and Versatile Design

The worm drive gearboxes feature a compact structure, allowing installation in space-constrained environments. Its universal mounting options, with the input shaft on the upper side and shaft hole output, provide flexibility for diverse machinery setups across industries like metallurgy and mining. - Low Noise and Vibration

Engineered for smooth operation, WPWKT worm gear speed reducers minimize noise and vibration during transmission. The precision-crafted worm and wheel components reduce friction and impact, ensuring stable performance, which is critical for maintaining operational comfort and equipment longevity in industrial settings. - Durable and Wear-Resistant Materials

Constructed with heat-treated 45# steel for the worm and tin bronze for the worm wheel, worm reducer gearboxes offer superior wear resistance. This durability enhances the lifespan of the reducer, reducing maintenance costs and ensuring reliable operation under demanding conditions. - High Load-Bearing Capacity

Worm and wheel gearboxes are designed to handle significant loads due to their robust construction and material strength. This capability makes them suitable for applications in heavy industries such as chemical processing and construction, where consistent performance under stress is essential. - Wide Application Range

These worm reduction gearboxes are versatile, supporting industries like plastics, rubber, and food processing. Their ability to provide stable speed reduction and high torque in various configurations makes them a preferred choice for machinery requiring precise control and reliable power transmission.

WPWKT Worm Gear Speed Reducer Applications

- Plastics Industry

In the plastics industry, WPWKT worm gear speed reducers are crucial for powering machinery such as plastic extruders, injection molding machines, and blow molding equipment. Their ability to provide precise speed reduction and high torque ensures efficient operation and consistent output quality during production processes. - Metallurgy Industry

Worm reducer gearboxes are widely used in metallurgy applications such as rolling mills, metal cutting machines, and processing equipment. Their high load capacity, wear resistance, and ability to handle heavy-duty operations make them ideal for handling the demanding requirements of metallurgy manufacturing and processing. - Mining Industry

In the mining sector, these worm drive gearboxes are employed in conveyor systems, crushers, and hoisting machinery. Their robust design, ability to achieve large torque outputs, and reliable performance under harsh conditions make them indispensable for transporting materials and processing ores efficiently. - Chemical Industry

The chemical industry relies on WPWKT worm gear gearboxes for mixing, pumping, and transporting chemicals in production plants. Their durability, smooth transmission, and resistance to impact make them suitable for handling the precise and often hazardous operations typical in chemical processing. - Construction Industry

In construction, worm gear reducers are used in equipment such as concrete mixers, winches, and lifting devices. Their compact design and high torque multiplication enable efficient operation in space-constrained environments, ensuring reliable performance in demanding construction tasks and heavy material handling. - Food and Beverage Industry

WPWKT worm gearboxes are ideal for food processing equipment like conveyors, mixers, and packaging machinery. Their stable transmission, low noise, and vibration-free performance make them suitable for maintaining hygiene and precision in food production lines, ensuring consistent product quality.

|  |

| Worm Gearbox for Plastic and Rubber Machinery | Worm Gearbox for Metallurgy Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Mining and Quarrying Industry |

Worm Gear Reducer Precautions for Use

- Regular Lubrication Maintenance

Ensure the gearworm gear drive gearbox box is adequately lubricated with the recommended type of lubricant to prevent excessive wear and overheating during operation. Regularly check the oil level and replace it as needed to maintain smooth performance and extend the lifespan of the gear reducer. - Avoid Overloading

Do not exceed the specified load capacity of the worm gear reducer. Overloading can cause excessive stress on the worm and wheel, leading to premature wear, reduced efficiency, or even mechanical failure, impacting the overall performance and reliability of the system. - Proper Installation Alignment

During installation, ensure the worm drive reduction gearbox is properly aligned with the connected machinery. Misalignment can lead to uneven load distribution, increased vibration, and excessive wear on the gears, which can compromise the efficiency and longevity of the equipment. - Monitor Operating Temperature

Keep the operating temperature of the gearbox within the specified range to avoid overheating. Excessive heat can degrade the lubricant, increase wear on components, and cause damage to the worm and worm wheel, leading to potential breakdowns and costly repairs. - Inspect for Unusual Noise or Vibration

Regularly monitor the worm gearbox reducer for unusual noise or excessive vibration during operation. These signs could indicate misalignment, insufficient lubrication, or internal damage. Addressing these issues promptly can prevent further damage and ensure the gearbox operates efficiently. - Clean and Protect from Contamination

Keep the gearbox clean and free from dust, moisture, and other contaminants that can cause corrosion or damage to internal components. Install protective covers if necessary, especially in harsh environments, to maintain the reducer’s performance and reduce maintenance requirements.

Additional information

| Edited by | Yjx |

|---|