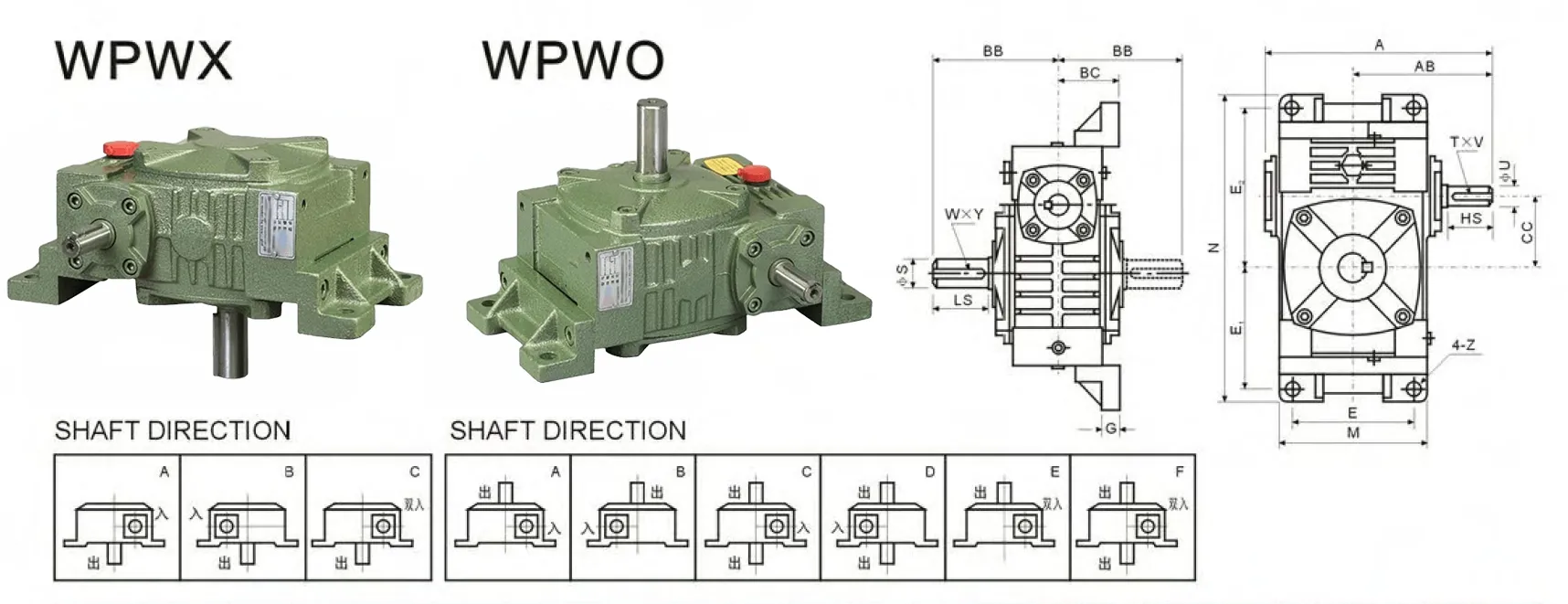

WPWO Worm Gear Reducers/Worm Gearbox

The WPWO worm gear reducer, commonly referred to as a worm gearbox, is a specialized mechanical power transmission device designed to reduce rotational speed while significantly increasing torque. This type of worm gearbox features a worm (a screw-like gear) and a worm wheel (a spur-like gear) that are arranged at a 90-degree angle, enabling a right-angle output orientation. The WPWO model is part of the WP series worm gearbox and is engineered with a robust cast iron housing, a single-stage worm gear mechanism, and a vertical upward output shaft with an input flange. It offers gear ratios ranging from 1:10 to 1:60, providing a compact and efficient solution for high torque applications.

The WPWO worm gear reducer, commonly referred to as a worm gearbox, is a specialized mechanical power transmission device designed to reduce rotational speed while significantly increasing torque. This type of worm gearbox features a worm (a screw-like gear) and a worm wheel (a spur-like gear) that are arranged at a 90-degree angle, enabling a right-angle output orientation. The WPWO model is part of the WP series worm gearbox and is engineered with a robust cast iron housing, a single-stage worm gear mechanism, and a vertical upward output shaft with an input flange. It offers gear ratios ranging from 1:10 to 1:60, providing a compact and efficient solution for high torque applications.

One of its key advantages is its ability to operate smoothly and quietly, with high resistance to shock loads. Additionally, under specific conditions, it exhibits self-locking characteristics, adding an extra layer of safety by preventing back-driving. These features make the WPWO worm gear speed reducer ideal for applications requiring precise control and durability, such as conveyor systems, elevators, and various industrial machinery.

WPWO Worm Gear Reducer Specifications

| Type: | WPWO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWO Worm Gearbox Dimensions

| Model | Ratio | A | AB | BB | BC | CC | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 74 | 45 | 40 | 95 | 187 | 70 | 72 | 97 | 12 | 10 |

| 50 | 175 | 108 | 97 | 50 | 50 | 111 | 226 | 90 | 90 | 110 | 14 | 12 | |

| 60 | 198 | 120 | 112 | 55 | 60 | 127 | 257 | 100 | 102 | 129 | 15 | 12 | |

| 70 | 231 | 140 | 131 | 65 | 70 | 152 | 305 | 120 | 120 | 155 | 20 | 15 | |

| 80 | 261 | 160 | 142 | 70 | 80 | 174 | 350 | 140 | 140 | 180 | 20 | 15 | |

| 100 | 322 | 190 | 169 | 90 | 100 | 224 | 410 | 190 | 165 | 215 | 22 | 15 | |

| 120 | 371 | 219 | 190 | 100 | 120 | 264 | 494 | 220 | 195 | 255 | 25 | 18 | |

| 135 | 422 | 249 | 210 | 110 | 135 | 304 | 559 | 260 | 230 | 285 | 30 | 18 | |

| 155 | 497 | 295 | 252 | 140 | 155 | 345 | 605 | 290 | 250 | 305 | 35 | 21 | |

| 175 | 534 | 314 | 255 | 150 | 175 | 374 | 675 | 320 | 273 | 348 | 40 | 21 | |

| 200 | 580 | 342 | 319 | 175 | 200 | 424 | 749 | 370 | 305 | 390 | 40 | 24 | |

| 250 | 705 | 420 | 385 | 200 | 250 | 510 | 920 | 440 | 375 | 475 | 45 | 28 |

| Input shaft | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 5 |

| 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 8 |

| 40 | 15 | 5×3 | 50 | 22 | 7×4 | 11 |

| 40 | 18 | 5×3 | 60 | 28 | 7×4 | 15.5 |

| 50 | 22 | 7×4 | 65 | 32 | 10×4.5 | 24 |

| 50 | 25 | 7×4 | 75 | 38 | 10×4.5 | 38 |

| 65 | 30 | 7×4 | 85 | 45 | 12×4.5 | 56 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 84 |

| 85 | 40 | 12×5.5 | 110 | 60 | 18×7 | 129 |

| 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 157 |

| 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 224 |

| 110 | 60 | 18×7 | 155 | 90 | 25×9 | 374 |

WPWO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWO Worm Gear Reducer Design Features

- Compact and Robust Structure

The WPWO worm gear reducers feature a compact design with a cast iron housing, ensuring durability and resistance to wear. Its space-saving configuration allows easy integration into various industrial setups, maintaining structural integrity under high loads and harsh operating conditions. - High Torque Output

Engineered for efficient power transmission, the worm drive gearboxes deliver high torque through its worm and worm wheel arrangement. With gear ratios ranging from 1:10 to 1:60, it provides substantial torque multiplication, ideal for heavy-duty applications like conveyors and material handling equipment. - Smooth and Quiet Operation

The WPWO worm reducer gearbox’s precision-engineered worm gear system ensures smooth, low-noise performance. The sliding contact between the worm and wheel minimizes vibrations, making it suitable for noise-sensitive environments, enhancing operational efficiency and extending equipment lifespan. - Self-Locking Capability

Under certain conditions, the worm gear speed reducers offer self-locking, preventing back-driving of the output shaft. This feature enhances safety and stability in applications like hoists or elevators, where unintended reverse motion could be hazardous, ensuring reliable load holding without additional braking mechanisms. - Vertical Upward Output Design

The WPWO worm and wheel gearboxes are designed with a vertical upward output shaft and input flange, facilitating easy mounting in space-constrained setups. This orientation supports versatile installation in machinery like mixers or agitators, optimizing space and alignment in industrial systems. - High Shock Load Tolerance

Built to withstand significant shock loads, the worm drive reduction gearbox’s robust construction and material quality ensure reliable performance under sudden stress. This makes it ideal for demanding applications such as crushers or presses, where intermittent high-impact forces are common.

WPWO Worm Drive Gearbox Applications

- Material Handling Industry

WPWO worm drive gearboxes are widely used in conveyor systems for material handling. Their high torque and compact design enable efficient movement of heavy loads in warehouses and distribution centers, ensuring reliable operation and precise speed control for bulk material transport. - Food and Beverage Processing

In food processing, worm gear gearboxes drive mixers, grinders, and packaging equipment. Their smooth, quiet operation and robust construction suit hygiene-sensitive environments, providing consistent performance in applications like dough mixing or bottling lines, where precision and durability are critical. - Construction Machinery

WPWO worm reducer gearboxes are integral to construction equipment like hoists and cranes. Their self-locking feature ensures safe load holding, while high torque output supports heavy lifting, making them ideal for rugged construction sites requiring dependable power transmission under demanding conditions. - Textile Manufacturing

Textile machinery, such as spinning and weaving equipment, relies on worm gear speed reducers for precise speed regulation. Their compact design and smooth operation ensure consistent fabric production, handling repetitive tasks with minimal vibration, enhancing efficiency in high-speed textile processing environments. - Chemical and Pharmaceutical Industry

WPWO worm gear reducers power agitators and pumps in chemical and pharmaceutical plants. Their corrosion-resistant materials and high shock tolerance ensure reliable performance in mixing and processing applications, maintaining operational stability in environments with strict regulatory and safety standards. - Mining and Heavy Machinery

The robust construction of the heavy duty worm drive gearbox makes it well-suited for mining applications. It is used in equipment like crushers, conveyors, and drilling machines, where it provides reliable power transmission, withstands shock loads, and operates effectively under harsh environmental conditions.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Food and Beverage Industry |

|  |

| Worm Gearbox for Construction Industry | Worm Gearbox for Textile Industry |

WPWO Worm Gear Reducer Maintenance Tips

- Regular Lubrication and Oil Changes

Proper lubrication is vital for the smooth operation and longevity of the WPWO worm gear reducer. Use the recommended lubricant type and check oil levels periodically. Replace the lubricant at specified intervals to prevent gear wear, overheating, and contamination buildup. - Inspect for Signs of Wear and Damage

Routinely inspect the worm gear drive gearbox for visible signs of wear, such as cracks, leaks, or corrosion on the housing and components. Pay close attention to the worm and worm wheel, as they are critical to maintaining proper speed reduction and torque transmission. - Monitor Operating Temperature

Excessive heat can indicate lubrication issues or overloading. Regularly monitor the operating temperature of the gearbox to ensure it remains within the manufacturer’s recommended range. High temperatures may lead to premature wear and damage to the internal components. - Check for Unusual Noises or Vibrations

Unusual noise or vibration during operation may indicate misalignment, insufficient lubrication, or internal damage. Address these issues promptly by identifying the root cause and making necessary adjustments or repairs to prevent further damage and ensure smooth performance. - Ensure Proper Alignment of Connected Components

Misalignment between the worm gear reducer gearbox and connected machinery can cause excessive stress on the worm gear. Regularly check and adjust the alignment of shafts, couplings, and other connected parts to maintain efficient power transmission and reduce wear on the gearbox. - Clean and Protect the Gearbox from Contaminants

Keep the gearbox clean and free from dust, dirt, and debris that can compromise its performance. In harsh environments, use protective covers or enclosures to shield the gearbox from contaminants, ensuring reliable operation and extending the lifespan of the equipment.

Additional information

| Edited by | Yjx |

|---|