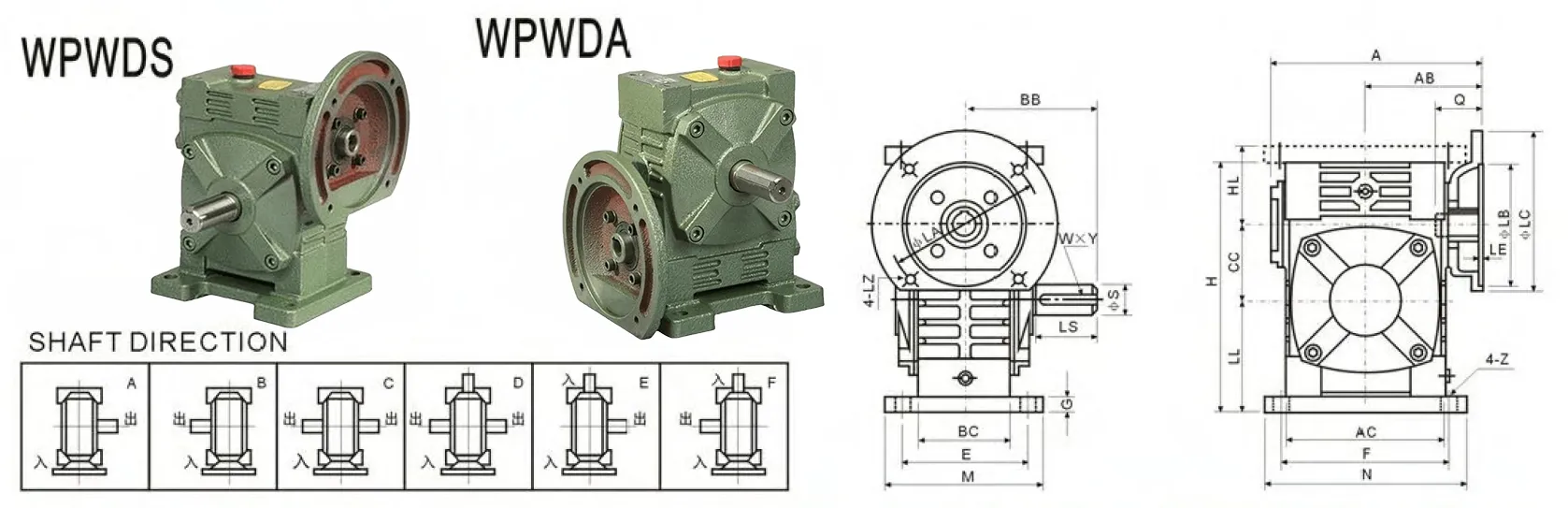

WPWDS Worm Gear Reducers/Worm Gearbox

WPWDS worm gear reducers, commonly referred to as worm gearboxes, are highly efficient mechanical devices engineered for power transmission across various industrial sectors. These worm gear speed reducers consist of a worm (a screw-like gear) and a worm wheel that interact to achieve precise motion and torque control. Encased in a durable cast iron housing, they are designed to withstand heavy-duty applications while maintaining low noise levels, typically below 50dB. Part of the WP series, the WPWDS worm gearbox is distinguished by its upper input shaft configuration, making it versatile for different setups.

WPWDS worm gear reducers, commonly referred to as worm gearboxes, are highly efficient mechanical devices engineered for power transmission across various industrial sectors. These worm gear speed reducers consist of a worm (a screw-like gear) and a worm wheel that interact to achieve precise motion and torque control. Encased in a durable cast iron housing, they are designed to withstand heavy-duty applications while maintaining low noise levels, typically below 50dB. Part of the WP series, the WPWDS worm gearbox is distinguished by its upper input shaft configuration, making it versatile for different setups. It offers gear ratios ranging from 1/10 to 1/60, ensuring adaptability for varied speed reduction requirements.

These worm drive gearboxes are known for their high torque output, compact design, and self-locking capabilities, which prevent reverse motion without additional brakes. They feature hardened tooth surfaces for enhanced wear resistance, a coaxial layout for operational efficiency, and flexible mounting options (horizontal or vertical). WPWDS worm reducer gearboxes are ideal for applications in motors, agricultural machinery, ceramics, dyeing, food processing, chemical industries, and packaging, where reliability, durability, and precision are vital.

WPWDS Worm Gear Reducer Specifications

| Type: | WPWDS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWDS Worm Gearbox Dimensions

| Model | Input Power(kW) | Ratio | A | AB | BB | AC | BC | CC | HL | LL | H | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/20 1/25 1/30 1/40 1/50 1/60 | 135 | 75 | 74 | 95 | 61 | 40 | 45 | 60 | 135 | 100 | 130 | 80 | 110 | 10 | 10 |

| 50 | 0.18 | 151 | 83 | 97 | 111 | 68 | 50 | 50 | 80 | 165 | 120 | 140 | 95 | 110 | 15 | 12 | |

| 60 | 0.37 | 167 | 91 | 112 | 127 | 76 | 60 | 60 | 93 | 195 | 130 | 150 | 105 | 120 | 18 | 12 | |

| 70 | 0.37 | 200 202 | 109 111 | 131 | 152 | 86 | 70 | 73 | 108 | 233 | 150 | 190 | 115 | 150 | 18 | 15 | |

| 80 | 0.75 1.5 | 225 | 125 | 142 | 169 | 102 | 80 | 83 | 123 | 268 | 170 | 220 | 135 | 180 | 18 | 15 | |

| 100 | 1.5 | 280 | 148 | 169 | 216 | 117 | 100 | 100 | 150 | 330 | 190 | 270 | 155 | 220 | 20 | 15 | |

| 120 | 2.2 2.2 | 333 | 181 | 190 | 256 | 124 | 120 | 120 | 180 | 395 | 230 | 320 | 180 | 260 | 25 | 18 | |

| 135 | 3.0 4.0 | 375 | 202 | 210 | 296 | 147 | 135 | 135 | 215 | 455 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 155 | 5.5 | 448 | 247 | 253 | 345 | 185 | 155 | 135 | 235 | 493 | 280 | 380 | 220 | 320 | 32 | 21 | |

| 175 | 5.5 7.5 | 481 | 262 | 255 | 374 | 192 | 175 | 160 | 260 | 558 | 310 | 410 | 250 | 350 | 37 | 21 | |

| 200 | 7.5 | 543 | 285 | 319 | 412 | 230 | 200 | 175 | 290 | 620 | 355 | 445 | 290 | 390 | 45 | 24 | |

| 250 | 11.0 15.0 | 615 | 330 | 385 | 500 | 285 | 250 | 200 | 350 | 750 | 460 | 560 | 380 | 480 | 50 | 28 |

| Flange | Input Hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kW) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 5 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 40 | 17 | 5×3 | 8 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 50 | 22 | 7×4 | 12.5 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 60 | 28 | 7×4 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 65 | 32 | 10×4.5 | 26 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 75 | 38 | 10×4.5 | 41.5 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 45 | 12×4.5 | 60 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 90 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 60 | 18×7 | 118 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 65 | 18×7 | 167 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 125 | 70 | 20×7.5 | 237 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 155 | 90 | 25×9 | 395 |

WPWDS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWDS Worm Gear Speed Reducer Advantages

1. High Torque Output and Efficiency

WPWDS worm gear speed reducers deliver substantial torque in a compact design, ideal for heavy-duty applications. Their efficient power transmission minimizes energy loss, ensuring optimal performance in industries like agriculture, ceramics, and food processing, while maintaining consistent output under demanding conditions.

2. Self-Locking Capability

The worm and worm wheel design provides inherent self-locking, preventing reverse motion without additional braking systems. This feature enhances safety and reliability in applications requiring precise positioning, such as conveyor systems or lifting equipment, ensuring stable operation even under variable loads.

3. Low Noise Operation

Engineered with precision, WPWDS worm gear reducers operate at noise levels below 50dB, creating a quieter working environment. The robust cast iron housing and high-quality gear meshing reduce vibrations, making them suitable for noise-sensitive settings like food processing or indoor machinery.

4. Versatile Mounting Options

These worm reducer gearboxes support flexible installation, available in horizontal or vertical configurations. This adaptability allows seamless integration into diverse systems, from packaging machines to chemical processing equipment, accommodating space constraints and varying operational requirements without compromising performance.

5. Durable and Low Maintenance

Constructed with hardened tooth surfaces and high-quality materials, WPWDS worm drive gearboxes resist wear and corrosion. Their sturdy design minimizes maintenance needs, ensuring long-term reliability in harsh industrial environments, reducing downtime and operational costs for businesses.

6. Wide Range of Gear Ratios

Offering ratios from 1/10 to 1/60, and up to 1/10,000 in double reduction models, worm reduction gearboxes provide precise speed control. This versatility supports applications requiring fine-tuned motion, such as dyeing or packing machinery, enhancing operational accuracy and efficiency.

WPWDS Right Angle Worm Gearbox Applications

1. Motors and Drives

WPWDS right-angle worm gearboxes are commonly used in motor-driven systems for speed reduction and torque amplification. Their compact design and high torque output make them ideal for electric motors in conveyor systems, cranes, and material handling equipment, enhancing efficiency and operational control.

2. Agricultural Machinery

In the agricultural sector, these worm and wheel gearboxes play a vital role in equipment like harvesters, seeders, and irrigation systems. Their durable construction and self-locking capabilities ensure reliable performance in harsh outdoor conditions, reducing maintenance needs and providing consistent operation for critical farming tasks.

3. Ceramics and Tile Production

WPWDS worm gear reducers are widely used in the ceramics industry, particularly in tile production machinery. Their ability to handle heavy loads and provide precise motion control ensures smooth operation of kilns, mixers, and presses, contributing to increased productivity and consistent product quality.

4. Dyeing and Textile Machinery

Textile and dyeing machines rely on worm reducer gearboxes for efficient power transmission. These gearboxes provide stable speed reduction and torque control, enabling precise operation of dyeing rollers, spinning machines, and fabric processing equipment, ensuring high-quality results in textile production and finishing.

5. Food Processing Equipment

Food processing industries utilize WPWDS worm drive gearboxes in applications such as conveyors, mixers, and packaging machines. Their low noise levels, robust construction, and compact design make them ideal for ensuring smooth and hygienic operation in environments that demand precision and reliability.

6. Chemical Processing Plants

In chemical processing, worm drive reduction gearboxes are used in mixers, pumps, and agitators, where high torque and speed control are essential. Their corrosion-resistant housing and ability to handle heavy loads make them suitable for challenging environments, ensuring safe and efficient operation in chemical production.

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Food and Beverage Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Conveyor Equipment |

WPWDS Worm Gear Reducer Lubrication Steps

1. Check the Lubricant Type

Before starting, ensure the correct lubricant type is selected according to the manufacturer’s recommendations. Typically, high-quality worm gear oil or synthetic lubricants specifically designed for worm gearboxes are required to reduce friction, enhance efficiency, and prevent premature wear of the components.

2. Clean the Gearbox Housing

Thoroughly clean the exterior of the gearbox to prevent contaminants like dust or debris from entering during the lubrication process. Inspect the oil filling port and surrounding areas to ensure no foreign materials compromise the integrity of the lubrication or the reducer’s performance.

3. Drain Old Oil Completely

If the gearbox has been in use, drain the old oil completely through the designated drain plug. Allow sufficient time for all the oil to exit, as residual oil may carry contaminants or degrade the performance of the new lubricant being added.

4. Inspect for Wear or Damage

While the gearbox is empty, inspect internal components such as the worm, worm wheel, and seals for wear or damage. Address any issues before refilling with new lubricant to ensure the gearbox operates smoothly and avoids further mechanical problems.

5. Refill with the Recommended Amount of Lubricant

Refill the gearbox with the correct quantity of the recommended lubricant through the oil filling port. Overfilling or underfilling can impact performance, so carefully measure the amount to ensure the lubricant adequately covers the gears without causing leaks or pressure issues.

6. Seal and Monitor Performance

After refilling, securely close the oil filling port and thoroughly clean any spillage. Run the gearbox under normal operating conditions and monitor for leaks, unusual noises, or overheating, which may indicate improper lubrication or other underlying mechanical issues.

Additional information

| Edited by | Yjx |

|---|