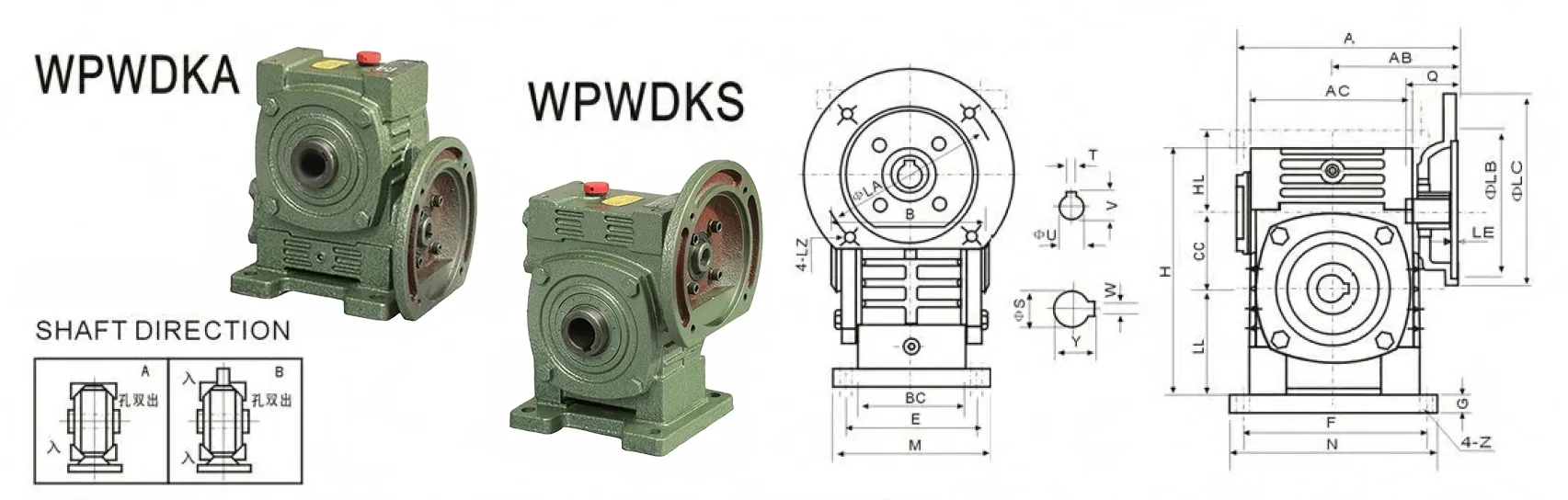

WPWDKA Worm Gear Reducers/Worm Gearbox

The WPWDKA worm gear reducer, also known as a worm gearbox, is a high-efficiency mechanical device designed for industrial transmission applications, offering robust torque output and compact design. It features a cast iron housing for durability, a worm gear (typically made of tin bronze for wear resistance), and a worm (crafted from heat-treated 45# steel) as the core transmission components. The WPWDKA worm gearbox integrates a universal worm reducer with a motor flange and a shaft hole output, with the input shaft positioned in the lower part of the gearbox.

The WPWDKA worm gear reducer, also known as a worm gearbox, is a high-efficiency mechanical device designed for industrial transmission applications, offering robust torque output and compact design. It features a cast iron housing for durability, a worm gear (typically made of tin bronze for wear resistance), and a worm (crafted from heat-treated 45# steel) as the core transmission components. The WPWDKA worm gearbox integrates a universal worm reducer with a motor flange and a shaft hole output, with the input shaft positioned in the lower part of the gearbox.

This configuration supports versatile mounting options, including horizontal or vertical orientations, and is compatible with standard IEC motors via B5 or B14a flanges. Available in frame sizes from 40 to 250 mm with center distances of 40–250 mm, it offers reduction ratios from 1/10 to 1/60, ensuring high torque and stable, low-noise operation. Its self-locking capability under certain conditions eliminates the need for additional braking devices, making it ideal for applications in conveying equipment, food processing, metallurgy, and chemical industries. The WPWDKA worm gear speed reducer’s compact structure, high load capacity, and minimal vibration enhance its reliability and longevity in demanding environments.

WPWDKA Worm Gear Reducer Specifications

| Type: | WPWDKA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWDKA Worm Gearbox Dimensions

| Model | Input Power(kW) | Ratio | A | AB | BB | AC | BC | CC | HL | LL | H | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/20 1/25 1/30 1/40 1/50 1/60 | 135 | 75 | 85 | 95 | 61 | 40 | 45 | 60 | 135 | 100 | 130 | 80 | 110 | 10 | 10 |

| 50 | 0.18 | 151 | 83 | 105 | 111 | 68 | 50 | 50 | 80 | 165 | 120 | 140 | 95 | 110 | 15 | 12 | |

| 60 | 0.37 | 167 | 91 | 110 | 127 | 76 | 60 | 60 | 93 | 195 | 130 | 150 | 105 | 120 | 18 | 12 | |

| 70 | 0.37 | 200 202 | 109 111 | 130 | 152 | 86 | 70 | 73 | 108 | 233 | 150 | 190 | 115 | 150 | 18 | 15 | |

| 80 | 0.75 1.5 | 225 | 125 | 150 | 169 | 102 | 80 | 83 | 123 | 268 | 170 | 220 | 135 | 180 | 18 | 15 | |

| 100 | 1.5 | 280 | 148 | 169 | 216 | 117 | 100 | 100 | 150 | 330 | 190 | 270 | 155 | 220 | 20 | 15 | |

| 120 | 2.2 2.2 | 333 | 181 | 190 | 256 | 124 | 120 | 120 | 180 | 395 | 230 | 320 | 180 | 260 | 25 | 18 | |

| 135 | 3.0 4.0 | 375 | 202 | 210 | 296 | 147 | 135 | 135 | 215 | 455 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 155 | 5.5 | 448 | 247 | 253 | 345 | 185 | 155 | 135 | 235 | 493 | 280 | 380 | 220 | 320 | 32 | 21 | |

| 175 | 5.5 7.5 | 481 | 262 | 255 | 374 | 192 | 175 | 160 | 260 | 558 | 310 | 410 | 250 | 350 | 37 | 21 | |

| 200 | 7.5 | 543 | 285 | 319 | 412 | 230 | 200 | 175 | 290 | 620 | 355 | 445 | 290 | 390 | 45 | 24 | |

| 250 | 11.0 15.0 | 615 | 330 | 385 | 500 | 285 | 250 | 200 | 350 | 750 | 460 | 560 | 380 | 480 | 50 | 28 |

| Flange | Input Hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | S | W×Y | (kW) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 16 | 6×18.8 | 5 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 20 | 6×22.8 | 8 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 25 | 8×28.3 | 12.5 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 35 | 10×38.3 | 26 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 40 | 12×43.3 | 41.5 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 45 | 14×48.8 | 60 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 60 | 18×64.4 | 90 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 70 | 20×74.9 | 118 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 80 | 22×85.4 | 167 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 85 | 22×90.4 | 237 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 110 | 28×116.4 | 395 |

WPWDKA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWDKA Worm Drive Gearbox Benefits

1. High Torque Output and Efficiency

The WPWDKA worm drive gearbox delivers exceptional torque for heavy-duty applications like conveyors and mixers. Its optimized worm and gear design ensures efficient power transmission, reducing energy loss and enhancing performance in industrial settings with demanding load requirements.

2. Compact and Versatile Design

With a compact structure, the worm gear reducers fit into space-constrained setups. Available in frame sizes from 40 to 250 mm, it supports multiple mounting options (horizontal or vertical), making it adaptable for diverse applications in industries like food processing and metallurgy.

3. Durable and Reliable Construction

Built with a cast iron housing and tin bronze worm gear, the WPWDKA worm reducer gearboxes offer superior durability. The heat-treated 45# steel worm ensures wear resistance, providing long-term reliability even in harsh environments, minimizing maintenance needs and extending operational lifespan.

4. Self-Locking Capability

The worm gear speed reducers' worm gear design provides self-locking under specific conditions, preventing back-driving without additional braking systems. This feature enhances safety and reduces system complexity, making it ideal for applications requiring precise positioning or load holding, such as lifting equipment.

5. Low Noise and Smooth Operation

Engineered for minimal vibration and noise, the WPWDKA worm reduction gearbox ensures quiet performance. Precision machining of the worm and gear components reduces friction and wear, creating a smooth operation that improves workplace comfort and maintains efficiency in continuous-use applications.

6. Wide Range of Ratios and Compatibility

Offering reduction ratios from 1/10 to 1/60, the worm gear reducers meet varied speed and torque needs. Its compatibility with standard IEC motors via B5 or B14a flanges simplifies integration, providing flexibility for industries like chemical processing and material handling.

Applications of WPWDKA Worm Reducer Gearbox

1. Conveyor Systems

The WPWDKA worm reducer gearbox is widely used in conveyor systems for material handling in industries like mining and logistics. Its high torque output and self-locking feature ensure reliable movement of heavy loads, enhancing efficiency and safety in continuous operations.

2. Food Processing Equipment

In food processing, the worm gear speed reducer drives machinery like mixers and grinders. Its compact design fits tight spaces, while the durable cast iron housing resists corrosion. The low-noise operation and precise speed control maintain consistent performance in hygiene-sensitive environments.

3. Metallurgical Machinery

The WPWDKA worm drive gearboxes support metallurgical applications, such as rolling mills and presses. Its robust construction withstands high loads and harsh conditions, while the wide range of reduction ratios allows precise torque adjustments, ensuring optimal performance in metal-forming processes.

4. Chemical Industry

In chemical plants, the worm gear gearboxes power agitators and pumps. Its self-locking capability prevents unintended movement, enhancing safety. The gearbox’s compatibility with IEC motors and high load capacity make it ideal for handling viscous materials under demanding operational conditions.

5. Packaging Machinery

The WPWDKA worm and wheel gearbox is integral to packaging equipment like sealing and labeling machines. Its smooth, low-vibration operation ensures precision, while the versatile mounting options allow integration into various setups, improving throughput and reliability in high-speed packaging lines.

6. Lifting and Hoisting Equipment

For cranes and hoists, the right angle worm gearbox provides high torque and self-locking features to secure heavy loads. Its durable worm gear design ensures stable performance under variable loads, making it suitable for construction and warehouse lifting applications.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Food and Beverage Industry |

|  |

| Worm Gearbox for Packaging Industry | Worm Gearbox for Chemical Industry |

Select the Right WPWDKA Worm Gearbox for Your Needs

- Determine the Required Torque and Load Capacity

Evaluate the torque requirements of your application and ensure the selected gearbox can handle the load. The worm gearbox offers various sizes and reduction ratios, making it essential to match the torque output to your operational needs. - Select the Appropriate Reduction Ratio

The gearbox’s reduction ratio determines the speed and torque output. Depending on whether your application requires high-speed rotation or increased torque, choose a ratio between 1/10 and 1/60 to ensure optimal performance for your specific machinery or workflow. - Consider Mounting Orientation and Space Constraints

Assess the available installation space and your preferred mounting orientation. The worm reduction gearbox supports horizontal and vertical mounting, making it suitable for compact or uniquely configured setups. Ensure the chosen model fits seamlessly into your system without requiring major modifications. - Check Compatibility with Motor Types

Ensure that the gearbox is compatible with your motor type. The WPWDKA worm gearbox supports standard IEC motors via B5 or B14a flanges. Verify the flange type and motor specifications to ensure proper alignment and efficient power transmission. - Evaluate Environmental Conditions and Material Durability

If your application operates in harsh conditions, such as exposure to chemicals, heat, or moisture, choose a gearbox with durable materials like cast iron housing and tin bronze gears. This ensures long-lasting performance and resistance to wear and environmental damage. - Account for Noise and Vibration Requirements

For applications where noise and vibration levels are critical, such as food processing or indoor operations, select a worm gearbox reducer model known for smooth and quiet performance. Precision machining ensures minimal noise, making it ideal for sensitive environments or prolonged use.

Additional information

| Edited by | Yjx |

|---|