WPWK Worm Gear Reducers/Worm Gearbox

WPWK worm gear reducers, also referred to as worm gearboxes, are a specialized type of WP series worm gear reducer designed for reliable and efficient power transmission in diverse industrial applications. These gearboxes feature a robust cast iron housing that ensures durability, excellent heat dissipation, and resistance to wear, making them suitable for demanding environments. Their design includes a universal-type shaft hole output and an upper-positioned input shaft, allowing for flexible mounting in horizontal or vertical orientations to suit various machinery layouts.

WPWK worm gear reducers, also referred to as worm gearboxes, are a specialized type of WP series worm gear reducer designed for reliable and efficient power transmission in diverse industrial applications. These gearboxes feature a robust cast iron housing that ensures durability, excellent heat dissipation, and resistance to wear, making them suitable for demanding environments. Their design includes a universal-type shaft hole output and an upper-positioned input shaft, allowing for flexible mounting in horizontal or vertical orientations to suit various machinery layouts.

The worm component is crafted from high-strength 45# steel, heat-treated to enhance durability and load capacity, while the worm wheel is typically made from wear-resistant tin bronze, ensuring long service life. WPWK worm gearboxes deliver high torque output with large reduction ratios, ranging up to 1/60 in single stages and up to 1/10,000 in double-stage configurations. They also exhibit self-locking properties under certain conditions, which can eliminate the need for external braking systems.

These worm reducer gearboxes are widely utilized in industries like plastics, metallurgy, mining, and chemical processing, owing to their stable transmission, low vibration, and minimal noise. Additionally, WPWK worm gear reducers are compatible with standard IEC motor flanges (B5/B14), ensuring seamless integration with various motor types.

WPWK Worm Gear Reducer Specifications

| Type: | WPWK Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

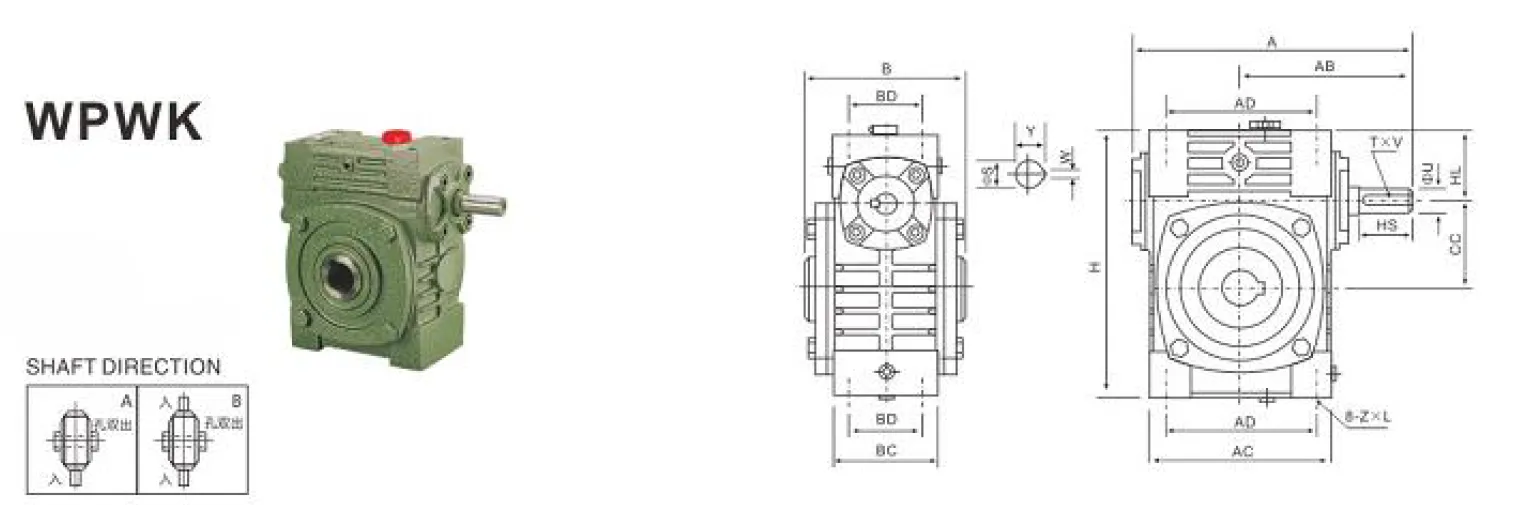

WPWK Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | AC | BC | AD | BD | CC | HL | H | Z×L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 149 | 89 | 90 | 95 | 61 | 78 | 42 | 40 | 35 | 125 | M6×12 |

| 50 | 175 | 107 | 110 | 111 | 68 | 85 | 50 | 50 | 35 | 150 | M6×18 | |

| 60 | 198 | 120 | 120 | 127 | 76 | 105 | 55 | 60 | 42 | 177 | M8×20 | |

| 70 | 231 | 140 | 132 | 152 | 86 | 125 | 65 | 70 | 55 | 215 | M10×25 | |

| 80 | 281 | 160 | 150 | 169 | 102 | 140 | 70 | 80 | 65 | 250 | M12×28 | |

| 100 | 322 | 190 | 174 | 216 | 117 | 180 | 90 | 100 | 80 | 310 | M12×30 | |

| 120 | 371 | 219 | 180 | 256 | 124 | 220 | 100 | 120 | 95 | 370 | M14×32 | |

| 135 | 433 | 260 | 214 | 296 | 147 | 260 | 110 | 135 | 105 | 425 | M16×35 | |

| 155 | 504 | 302 | 256 | 345 | 185 | 280 | 120 | 155 | 103 | 461 | M16×35 | |

| 175 | 545 | 325 | 282 | 374 | 192 | 320 | 140 | 175 | 123 | 521 | M16×35 | |

| 200 | 587 | 350 | 324 | 412 | 230 | 360 | 150 | 200 | 130 | 575 | M20×36 | |

| 250 | 705 | 420 | 400 | 500 | 285 | 420 | 190 | 250 | 150 | 700 | M24×42 | |

| 250 | 705 | 420 | 400 | 500 | 285 | 420 | 190 | 250 | 150 | 700 | M24×42 |

| Input shaft | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 16 | 5×18.3 | 4 |

| 30 | 12 | 4×2.5 | 20 | 8×22.8 | 6.5 |

| 40 | 15 | 5×3 | 25 | 8×28.3 | 9 |

| 40 | 18 | 6×3.5 | 30 | 8×33.3 | 13 |

| 50 | 22 | 6×3.5 | 35 | 10×38.3 | 21 |

| 50 | 25 | 8×4 | 40 | 12×43.3 | 34 |

| 65 | 30 | 8×4 | 45 | 14×48.8 | 51 |

| 75 | 35 | 10×5 | 60 | 18×64.4 | 78 |

| 85 | 40 | 12×5 | 70 | 20×74.9 | 102 |

| 85 | 45 | 14×5.5 | 80 | 22×85.4 | 142 |

| 95 | 50 | 14×5.5 | 95 | 22×90.4 | 202 |

| 110 | 60 | 18×7 | 110 | 28×116.4 | 340 |

WPWK Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWK Worm Gear Reducer Benefits

- High Torque Output and Efficiency

WPWK worm gear reducers deliver substantial torque through precise worm and wheel meshing, enabling efficient power transmission. Their design ensures high load-carrying capacity, making them ideal for heavy-duty applications in industries like metallurgy and mining, enhancing operational performance. - Compact and Versatile Design

The compact cast iron housing of worm drive gearboxes allows for space-saving installation. With universal shaft hole output and flexible mounting options (horizontal or vertical), they adapt to diverse machinery setups, ensuring seamless integration in constrained or complex industrial environments. - Low Noise and Vibration

Engineered for quiet operation, WPWK worm reducer gearboxes minimize noise and vibration through robust construction and precision manufacturing. This feature enhances workplace safety and comfort, particularly in continuous-operation settings like chemical processing or conveyor systems, while maintaining consistent performance. - Self-Locking Capability

Under specific conditions, worm gear speed reducers offer self-locking, preventing reverse motion without additional braking systems. This feature ensures safety and reliability in applications like hoists or lifts, reducing maintenance costs and enhancing operational control in critical machinery setups. - Durable and Reliable Materials

Constructed with a high-strength 45# steel worm and a wear-resistant tin bronze wheel, WPWK right angle worm gear reducers ensure long-lasting performance. Their corrosion-resistant design withstands harsh industrial environments, reducing downtime and maintenance needs in sectors like plastics and mining. - Wide Reduction Ratio Range

Worm drive reduction gearboxes provide large reduction ratios, up to 1/60 in single-stage or 1/10,000 in double-stage configurations. This versatility allows precise speed control in applications like packaging or material handling, optimizing machinery performance and energy efficiency across various industries.

WPWK Worm Gear Speed Reducer Applications

- Metallurgy Industry

WPWK worm gear speed reducers are extensively used in metallurgical equipment like rolling mills and conveyors. Their high torque output and robust cast iron housing ensure reliable performance under heavy loads, enabling precise speed control and durability in harsh, high-temperature environments. - Mining Industry

In mining operations, worm gear reducers drive machinery such as crushers and belt conveyors. Their self-locking feature and large reduction ratios provide safe, controlled motion, while the durable construction withstands abrasive conditions, ensuring consistent performance in demanding underground or open-pit settings. - Chemical Processing

WPWK right angle worm gearboxes are ideal for chemical plants, powering mixers and pumps. Their low noise and vibration characteristics enhance workplace safety, and corrosion-resistant materials ensure longevity despite exposure to aggressive chemicals, supporting stable operation in continuous processing systems. - Plastics Industry

Used in plastic extrusion and molding machines, worm drive gearboxes offer precise speed regulation and high torque. Their compact design allows easy integration into complex setups, while the self-locking capability ensures safety, optimizing production efficiency in plastic manufacturing processes. - Material Handling

WPWK worm reducer gearboxes are critical in material handling systems like conveyor belts and hoists. Their versatile mounting options and wide reduction ratios enable smooth, controlled movement of heavy loads, improving operational efficiency and reliability in warehouses and logistics facilities. - Food and Beverage Industry

In food processing equipment such as mixers and packaging machines, worm reduction gearboxes provide quiet, efficient operation. Their robust design and compatibility with IEC motor flanges ensure hygienic, reliable performance, meeting stringent industry standards while maintaining consistent production speeds.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Chemical Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Plastic and Rubber Machinery |

WPWK Worm Gearbox Repairs

- Regular Inspection and Diagnosis

Routine inspection is crucial to identify early signs of wear, misalignment, or damage in the gearbox. Diagnosing issues such as unusual noise, excessive vibration, or oil leakage ensures timely repairs and prevents potential failures that could disrupt operations. - Gear and Bearing Replacement

Over time, the worm wheel and worm gear may wear out due to constant operation. Replacing these components with high-quality parts restores the gearbox's efficiency. Similarly, worn-out bearings should be replaced to avoid increased friction and maintain smooth performance. - Lubrication Maintenance

Proper lubrication is essential for reducing friction and preventing overheating. During repairs, old or contaminated lubricant should be drained and replaced with the manufacturer-recommended oil. Ensuring the correct oil level and quality extends the gearbox's lifespan and enhances performance. - Seal and Gasket Replacement

Damaged seals and gaskets can lead to oil leaks, reducing lubrication efficiency and causing internal damage. During repairs, all seals and gaskets should be inspected and replaced if necessary to ensure the gearbox remains properly sealed and protected from contaminants. - Alignment and Balancing Adjustments

Misalignment of the worm shaft or coupling can cause excessive wear and noise. Repairing the worm drive reduction gearbox involves realigning these components and balancing the system to reduce vibrations. Proper alignment ensures long-term operational stability and minimizes mechanical stress. - Testing After Repairs

After completing repairs, the worm gear drive gearbox should be thoroughly tested under actual operating conditions. This includes checking for noise, vibration, and temperature levels. Conducting proper testing ensures the repairs were successful and confirms the gearbox is fully functional before returning it to service.

Additional information

| Edited by | Yjx |

|---|