WPWD Worm Gear Reducers/Worm Gearbox

WPWD worm gear reducers, also known as worm gearboxes, are specialized mechanical devices engineered for efficient power transmission in various industrial applications. These reducers are characterized by their compact design, featuring a worm (a screw-like gear) and a worm wheel (a spur-like gear) arranged at a 90-degree angle. This configuration enables high torque output and substantial speed reduction, making them ideal for heavy-duty operations. The WPWD series worm reducer gearbox, part of the renowned WP series worm gearbox, includes a solid output shaft and a lower input shaft configuration, ensuring efficient performance.

WPWD worm gear reducers, also known as worm gearboxes, are specialized mechanical devices engineered for efficient power transmission in various industrial applications. These reducers are characterized by their compact design, featuring a worm (a screw-like gear) and a worm wheel (a spur-like gear) arranged at a 90-degree angle. This configuration enables high torque output and substantial speed reduction, making them ideal for heavy-duty operations. The WPWD series worm reducer gearbox, part of the renowned WP series worm gearbox, includes a solid output shaft and a lower input shaft configuration, ensuring efficient performance.

Constructed with durable cast iron housing, high-quality 45# steel worms, and tin bronze worm wheels, they offer superior wear resistance and load-bearing capacity. With reduction ratios ranging from 1/10 to 1/60, these worm gear speed reducers provide self-locking functionality, low noise, and minimal vibration. Their robust design makes them suitable for demanding industries such as plastics, metallurgy, mining, lifting, and chemicals.

WPWD Worm Gear Reducer Specifications

| Type: | WPWD Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

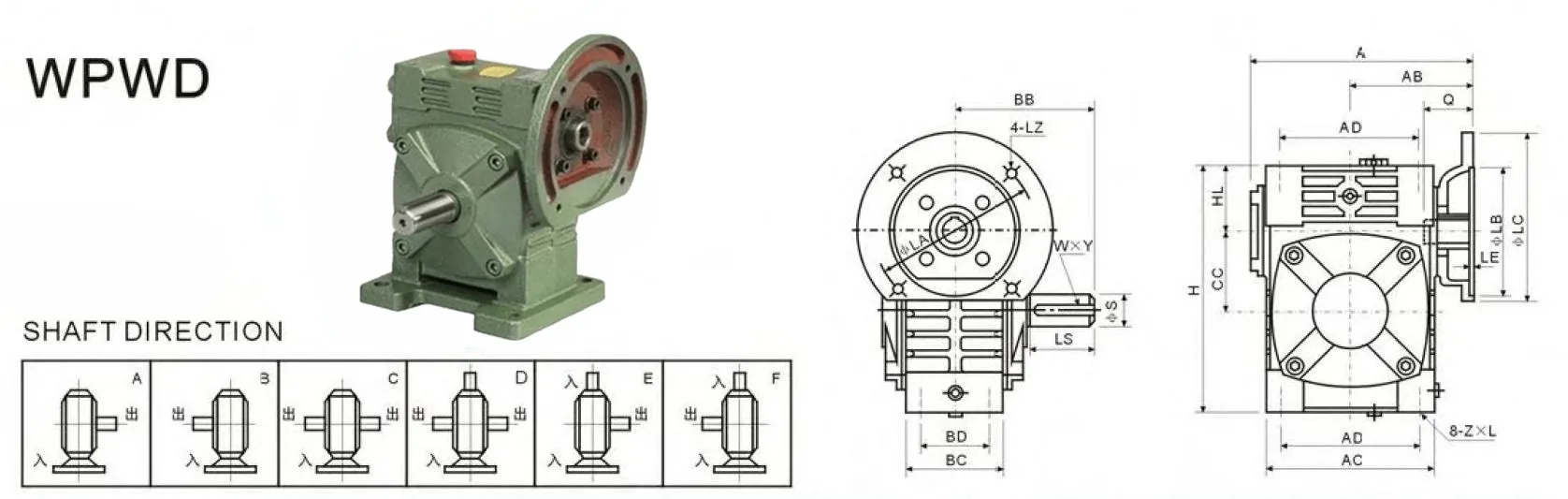

WPWD Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | A | AB | BB | AC | BC | AD | BD | CC | HL | H | Z×L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 135 | 75 | 74 | 95 | 61 | 78 | 42 | 40 | 35 | 125 | M6×12 |

| 50 | 0.18 | 151 | 83 | 97 | 111 | 68 | 85 | 50 | 50 | 35 | 150 | M6×18 | |

| 60 | 0.37 | 157 | 91 | 112 | 127 | 76 | 105 | 55 | 60 | 42 | 177 | M8×20 | |

| 70 70 | 0.37 | 200 | 109 | 131 | 152 | 86 | 125 | 65 | 70 | 55 | 215 | M10×25 | |

| 80 | 0.75 1.5 | 225 | 125 | 142 | 169 | 102 | 140 | 70 | 80 | 65 | 250 | M12×28 | |

| 100 | 1.5 | 280 | 148 | 169 | 216 | 117 | 180 | 90 | 100 | 80 | 310 | M12×30 | |

| 120 | 2.2 1.5 | 333 | 181 | 190 | 256 | 124 | 220 | 100 | 120 | 95 | 370 | M14×32 | |

| 135 | 3.0 4.0 | 375 | 202 | 210 | 296 | 147 | 260 | 110 | 135 | 105 | 425 | M16×35 | |

| 155 | 5.5 | 448 | 247 | 252 | 345 | 185 | 280 | 120 | 155 | 103 | 461 | M16×35 | |

| 175 | 5.5 7.5 | 481 | 262 | 255 | 374 | 192 | 320 | 140 | 175 | 123 | 521 | M16×35 | |

| 200 | 11.0 | 543 | 285 | 319 | 412 | 230 | 360 | 150 | 200 | 130 | 575 | M20×36 | |

| 250 | 11.0 15.0 | 615 | 330 | 385 | 500 | 285 | 420 | 190 | 250 | 150 | 700 | M24×42 |

| Flange | Input Hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 4 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 40 | 17 | 5×3 | 7 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 50 | 22 | 7×4 | 10 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 60 | 28 | 7×4 | 14.5 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 65 | 32 | 10×4.5 | 23 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 75 | 38 | 10×4.5 | 36.5 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 45 | 12×4.5 | 54 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 83 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 60 | 18×7 | 110 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 65 | 18×7 | 156 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 125 | 70 | 20×7.5 | 222 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 155 | 90 | 25×9 | 376 |

WPWD Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWD Worm Gear Speed Reducer Advantages

- High Torque Output and Large Reduction Ratios

The WPWD worm gear speed reducers are designed to deliver exceptional torque output, making them suitable for heavy-duty industrial applications. With reduction ratios ranging from 1/10 to 1/60, they efficiently handle high-speed input and provide significant speed reduction. This capability ensures smooth power transmission in demanding operations, such as lifting and mining. - Durable Construction for Long-Term Use

Built with a cast iron housing, 45# steel for the worm, and a tin bronze worm wheel, these worm gear reducers offer excellent wear resistance and long-lasting performance. Their rugged construction allows them to withstand high loads and harsh environmental conditions, ensuring reliability in challenging applications like metallurgy and chemical processing. - Compact Design for Space Efficiency

The WPWD worm drive gearbox features a compact structure, allowing for easy installation in limited spaces. This small footprint not only saves valuable floor space but also simplifies integration into existing machinery. The compact design ensures efficient performance without the need for bulky additional components, making them versatile across industries. - Self-Locking Functionality for Safety

The self-locking properties of worm reducer gearboxes prevent back-driving under load, enhancing safety during operation. This feature eliminates the need for separate braking systems, reducing complexity and cost in applications where stability and control are critical, such as lifting devices and conveyors. - Low Noise and Vibration During Operation

These worm gear reducer gearboxes are engineered for quiet and smooth operation, minimizing noise and vibration. This makes them ideal for environments where noise levels need to be controlled, such as manufacturing facilities or indoor applications. The reduced vibrations also contribute to the longevity of connected machinery. - Versatility Across Industrial Applications

Thanks to their robust design and ability to transmit power efficiently, WPWD worm drive reduction gearboxes are widely used in industries like plastics, mining, lifting, and metallurgy. Their adaptability to various mechanical systems ensures optimal performance, supporting diverse industrial processes with minimal maintenance requirements.

WPWD Worm Reducer Gearbox Applications

- Plastics Industry

In the plastics industry, WPWD worm gear reducers are extensively used in machines like extruders and injection molding systems. Their ability to provide high torque and precise speed reduction ensures efficient operation, enabling the production of high-quality plastic components and products. - Metallurgy and Steel Processing

The robust construction of worm gearboxes makes them ideal for metallurgy applications, including rolling mills and steel processing equipment. They handle heavy loads and ensure smooth power transmission, which is crucial for shaping, cutting, and forming metals with precision and efficiency. - Mining Industry

WPWD right angle worm gearboxes play a vital role in mining machinery, such as conveyors, crushers, and drilling equipment. Their high load-bearing capacity and self-locking function ensure the safe and efficient operation of equipment in demanding environments with heavy material handling. - Lifting and Hoisting Equipment

In lifting and hoisting systems, these worm gear speed reducers are used to achieve controlled motion and stable operation. Their self-locking properties enhance safety by preventing the reversal of motion under load, which is essential in cranes, elevators, and similar equipment. - Chemical Processing Plants

Chemical industries rely on worm drive gearboxes for equipment like mixers, agitators, and pumps. These reducers ensure precise speed control and smooth operation, which is critical for handling sensitive processes and maintaining the consistency of chemical reactions or material blending. - Conveying Systems

WPWD self locking worm gear reducers are widely employed in conveyor systems used for material handling across industries. Their compact design allows easy integration into conveyor machinery, while their ability to reduce speed and provide high torque ensures efficient and reliable movement of goods.

|  |

| Worm Gearbox for Plastic and Rubber Machinery | Worm Gearbox for Chemical Industry |

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Metallurgy Industry |

WPWD Worm Gear Reducer Maintenance

- Regular Lubrication

Proper lubrication is critical for the smooth operation and longevity of worm gear speed reducers. Check the oil level frequently and use the recommended lubricant type. Replace the oil periodically to prevent contamination, reduce friction, and avoid premature wear of internal components. - Inspection for Wear and Tear

Conduct routine inspections to check for signs of wear or damage on the worm, worm wheel, and housing. Identifying issues early, such as cracks, gear misalignment, or excessive wear, can prevent costly repairs and ensure optimal reducer performance over time. - Monitor Operating Temperature

Excessive heat during operation can indicate lubrication issues or overloading. Regularly monitor the operating temperature and ensure it stays within the manufacturer’s recommended range. Overheating can degrade the lubricant and damage internal components, leading to reduced efficiency and lifespan. - Check for Loose Bolts and Connections

Inspect all bolts, flanges, and mounting parts to ensure they remain tight and secure. Loose connections can cause misalignment, vibration, and noise, which may harm the gearbox and connected machinery. Tighten any loose components during routine maintenance checks. - Clean the Gearbox Exterior

Keep the exterior of the worm gearbox reducer clean and free from dust, debris, and contaminants. A dirty surface can trap heat and accelerate corrosion. Cleaning the housing regularly helps maintain optimal heat dissipation and prevents external damage to the gearbox. - Prevent Overloading and Misuse

Ensure the reducer operates within its rated load and speed limits. Overloading or running the worm drive reduction gearbox at excessive speeds can cause internal damage, reduce efficiency, and shorten its lifespan. Use the equipment according to its specifications to maximize performance and durability.

Additional information

| Edited by | Yjx |

|---|