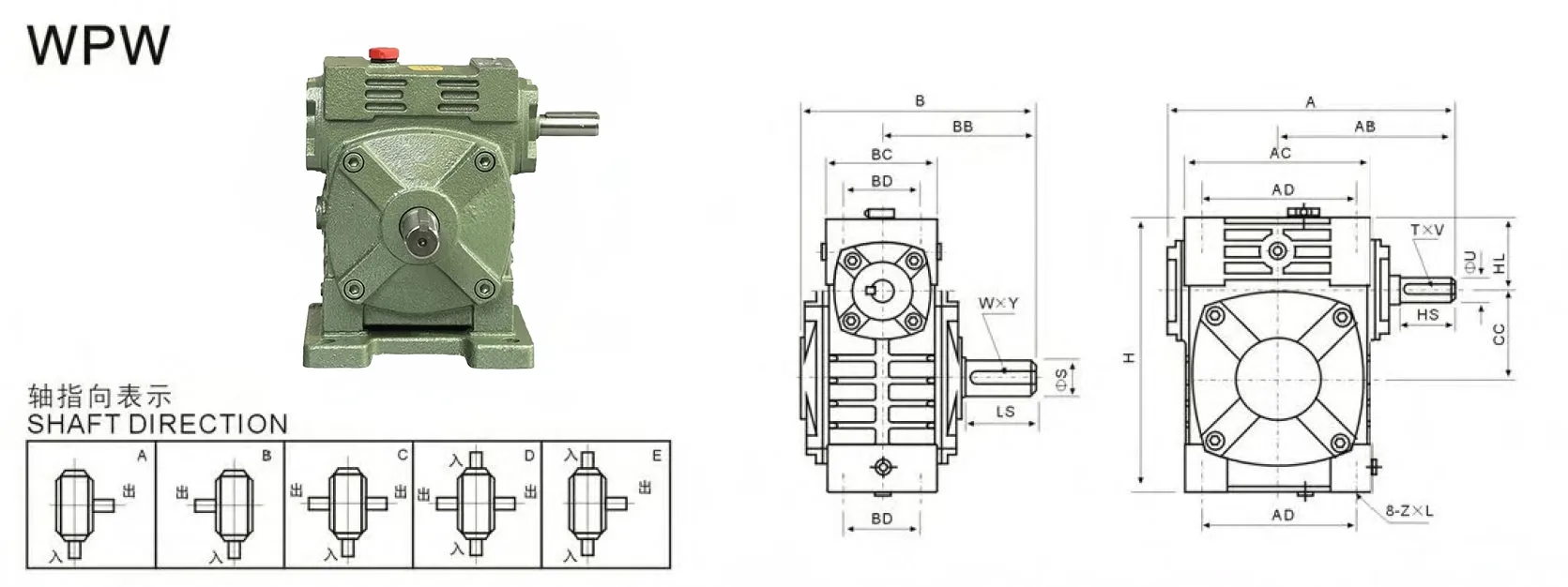

WPW Worm Gear Reducers/Worm Gearbox

WPW worm gear reducers, also known as WPW worm gearboxes, are mechanical power transmission devices designed for efficient speed reduction and torque multiplication in compact spaces. They consist of a worm (a screw-like gear) and a worm wheel (a toothed gear), typically enclosed in a cast iron or aluminum housing. The WPW series, part of the broader WP series worm gear reducer, features a universal mounting design, allowing flexible installation in various orientations, such as horizontal or vertical shaft configurations.

WPW worm gear reducers, also known as WPW worm gearboxes, are mechanical power transmission devices designed for efficient speed reduction and torque multiplication in compact spaces. They consist of a worm (a screw-like gear) and a worm wheel (a toothed gear), typically enclosed in a cast iron or aluminum housing. The WPW series, part of the broader WP series worm gear reducer, features a universal mounting design, allowing flexible installation in various orientations, such as horizontal or vertical shaft configurations.

Key features include a high reduction ratio (up to 100:1 in single-stage, 10,000:1 in double-stage), self-locking capability under certain conditions, and low noise operation due to precision-machined components like hardened worm shafts and bronze worm wheels. These worm gear speed reducers are widely used in applications like conveyors, hoists, and agricultural machinery for their durability, compact structure, and ability to handle high-torque loads with minimal maintenance.

WPW Worm Gear Reducer Specifications

| Type: | WPW Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPW Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | BB | AC | BC | AD | BD | CC | HL | H | Z×L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/20 1/25 1/30 1/40 1/50 1/60 |

143 | 87 | 114 | 74 | 95 | 61 | 78 | 42 | 40 | 35 | 125 | M6×12 |

| 50 | 175 | 108 | 150 | 97 | 111 | 68 | 85 | 50 | 50 | 35 | 150 | M6×18 | |

| 60 | 198 | 120 | 168 | 112 | 127 | 76 | 105 | 55 | 60 | 42 | 177 | M8×20 | |

| 70 | 231 | 140 | 194 | 131 | 152 | 86 | 125 | 65 | 70 | 55 | 215 | M10×25 | |

| 80 | 261 | 160 | 214 | 142 | 169 | 102 | 140 | 70 | 80 | 65 | 250 | M12×28 | |

| 100 | 322 | 190 | 254 | 169 | 216 | 117 | 180 | 90 | 100 | 80 | 310 | M12×30 | |

| 120 | 371 | 219 | 282 | 190 | 256 | 124 | 220 | 100 | 120 | 95 | 370 | M14×32 | |

| 135 | 422 | 249 | 317 | 210 | 296 | 147 | 260 | 110 | 135 | 105 | 425 | M16×35 | |

| 155 | 497 | 295 | 382 | 252 | 345 | 185 | 280 | 120 | 155 | 103 | 481 | M16×35 | |

| 175 | 534 | 314 | 372 | 255 | 374 | 192 | 320 | 140 | 175 | 123 | 521 | M16×35 | |

| 200 | 580 | 342 | 456 | 319 | 412 | 230 | 360 | 150 | 200 | 130 | 575 | M20×36 | |

| 250 | 705 | 420 | 552 | 385 | 500 | 285 | 420 | 190 | 250 | 150 | 700 | M24×42 |

| Input shaft | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 4 |

| 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 6.5 |

| 40 | 15 | 5×3 | 50 | 22 | 7×4 | 9 |

| 40 | 18 | 5×3 | 60 | 28 | 7×4 | 13 |

| 50 | 22 | 7×4 | 65 | 32 | 10×4.5 | 21 |

| 50 | 25 | 7×4 | 75 | 38 | 10×4.5 | 34 |

| 65 | 30 | 7×4 | 85 | 45 | 12×4.5 | 51 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 78 |

| 85 | 40 | 12×5 | 110 | 60 | 18×7 | 102 |

| 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 142 |

| 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 202 |

| 110 | 60 | 18×7 | 155 | 90 | 25×9 | 340 |

WPW Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPW Worm Gear Reducer Features

- High Reduction Ratios

WPW worm gear reducers offer a wide range of reduction ratios, from 10:1 to 100:1 in single-stage designs and up to 10,000:1 in double-stage configurations. This versatility allows precise speed adjustment and torque multiplication to meet diverse industrial requirements, ensuring optimal performance. - Compact and Durable Design

Built with robust cast iron or aluminum housings, worm drive gearboxes are engineered for strength and longevity. Their compact structure saves valuable space while maintaining excellent resistance to wear, vibration, and harsh environmental conditions, making them ideal for demanding applications in limited installation areas. - Universal Mounting Options

The WPW series worm reducer gearbox features a universal mounting design, allowing installation in various orientations, such as horizontal, vertical, or inclined positions. This flexibility ensures compatibility with different machinery setups, enhancing adaptability and simplifying integration into existing systems without additional modifications. - Self-Locking Capability

Under specific conditions, worm gearboxes exhibit self-locking characteristics, preventing reverse motion without needing external braking mechanisms. This feature is particularly useful in applications like hoists and lifts, where safety and stability during operation are critical for productivity and reliability. - Low Noise and Smooth Operation

Precision-machined components, including hardened worm shafts and bronze worm wheels, reduce friction and improve efficiency. This results in quieter performance and smoother motion, ensuring minimal operational noise, making WPW worm gear speed reducers suitable for environments that require reduced sound levels. - Efficient Heat Dissipation: WPW right angle worm gearboxes incorporate cooling fins and efficient lubrication to manage heat generated during operation. This design prevents overheating, maintains performance under high loads, and extends service life, making them reliable for continuous-duty applications in industries like agriculture and material handling.

WPW Worm Drive Gearbox Applications

-

Conveyor Systems

WPW worm drive gearboxes are widely used in conveyor systems for material handling in industries like mining and manufacturing. Their high reduction ratios ensure precise speed control, enabling smooth transport of heavy loads with minimal power consumption and reliable performance. -

Agricultural Machinery

In agricultural equipment such as seeders and harvesters, worm wheel gearboxes provide robust torque for driving components. Their durable construction withstands harsh outdoor conditions, ensuring consistent operation in tasks like soil tilling or crop processing, enhancing productivity and equipment longevity. -

Hoists and Lifting Equipment

WPW worm reducer gearboxes are ideal for hoists and cranes due to their self-locking feature, which prevents load slippage. This ensures safe and controlled lifting in construction or warehousing, where precise load positioning and reliable holding are critical for operational safety. -

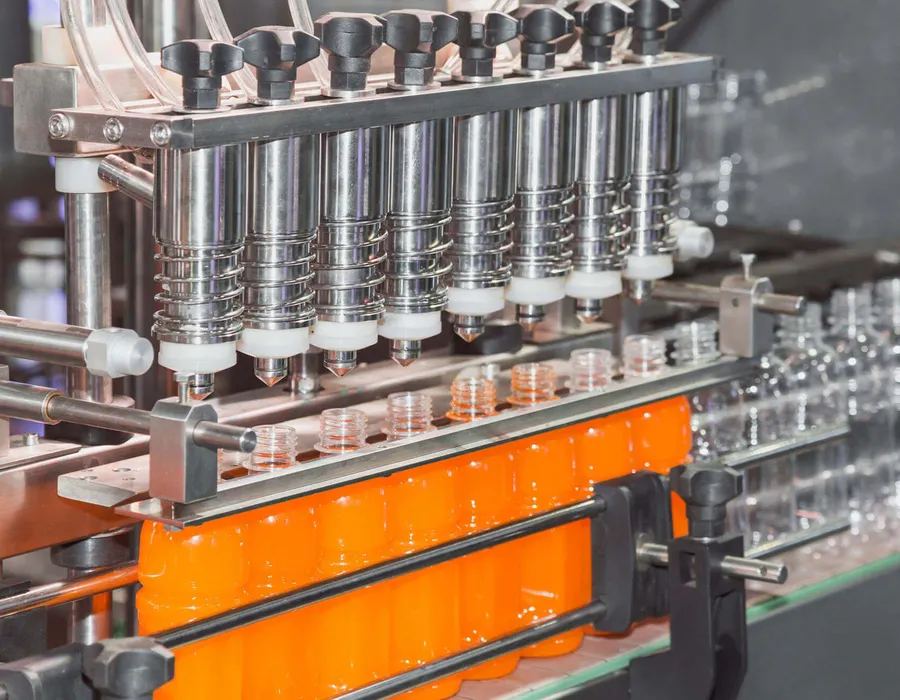

Packaging Machinery

In packaging lines for food, pharmaceuticals, and consumer goods, worm gear reducers deliver smooth and quiet operation. Their compact design fits into tight spaces, providing precise speed control for tasks like sealing, labeling, or filling, ensuring efficiency and high throughput. -

Textile Industry

WPW worm reduction gearboxes power textile machinery, such as spinning or weaving equipment. Their ability to handle high-torque loads and maintain consistent speeds supports precise fabric production, while their low maintenance requirements reduce downtime in fast-paced textile manufacturing environments. -

Mixers and Agitators

In chemical and food processing industries, worm gear speed reducers drive mixers and agitators for blending liquids or powders. Their high torque output and smooth operation ensure uniform mixing, while robust housing protects against corrosive materials, supporting reliable and continuous production processes.

|

|

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Construction Industry |

|

|

| Worm Gearbox for Textile Industry | Worm Gearbox for Packaging Industry |

WPW Worm Gearbox Oil Level Check

- Preparation and Safety

Before checking the oil level in a worm gearbox, ensure the equipment is powered off and cooled down to avoid burns or injuries. Gather necessary tools, including a clean rag, wrench, and flashlight, and review the manual for specific instructions. - Locate the Oil Level Plug

Identify the oil level plug on the gearbox, typically found on the side of the housing. Consult the worm gear gearbox manual for the exact location, as it varies by model. Ensure the gearbox is on a level surface for an accurate reading. - Clean the Area

Wipe the area around the oil level plug with a clean rag to prevent dirt or debris from entering the gearbox. Contamination can damage internal components, so maintaining a clean workspace is critical for preserving the gearbox’s performance and longevity. - Remove the Oil Level Plug

Use a wrench to carefully remove the oil level plug. Turn it counterclockwise until it is fully detached. Handle the plug gently to avoid damaging the threads, which could lead to leaks or improper sealing during reassembly. - Check Oil Level

Observe the oil level through the plug opening using a flashlight if needed. The oil should be just below or at the bottom edge of the hole. If the level is too low, add the recommended lubricant as specified in the manual. - Reinstall and Verify

Replace the oil level plug securely, tightening it clockwise to ensure a proper seal. Check for leaks after reassembly and run the gearbox briefly to confirm normal operation. Regular oil checks maintain efficiency and extend the worm reducer gearbox’s service life.

Additional information

| Edited by | Yjx |

|---|