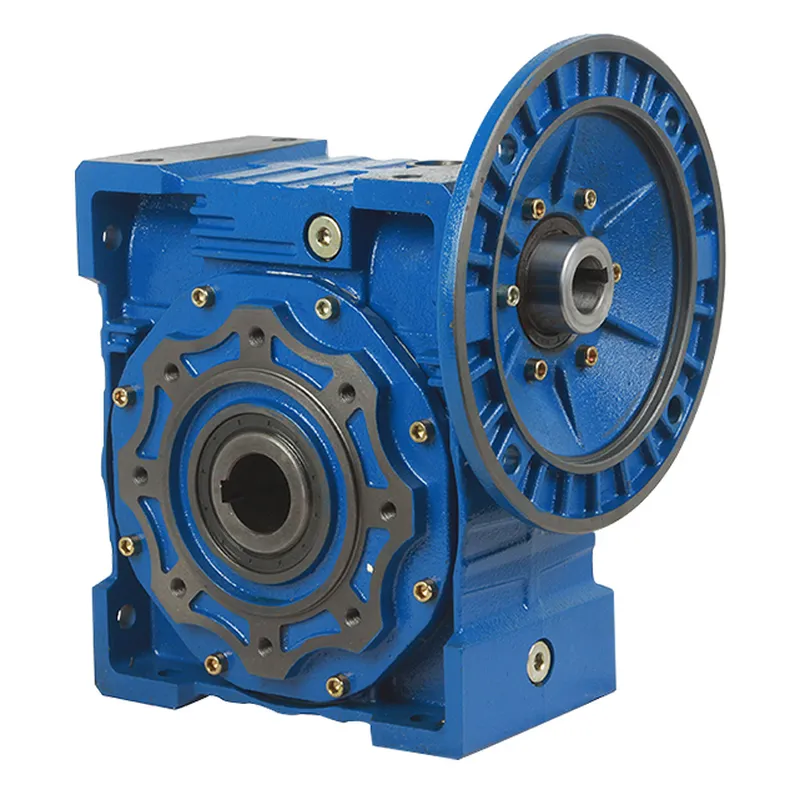

WPDA Worm Gear Reducers/Worm Gearbox

The WPDA worm gear reducer, part of the WP series worm gearbox, is a versatile and efficient power transmission device designed for various industrial applications. It features a worm gear mechanism that provides high torque output, smooth operation, and compact design. The WPDA model, along with WPXS, WPDO, and WPDX, incorporates a motor flange input, allowing direct connection to a motor without contacting transmission components, enhancing user safety by eliminating the need for a safety cover.

The WPDA worm gear reducer, part of the WP series worm gearbox, is a versatile and efficient power transmission device designed for various industrial applications. It features a worm gear mechanism that provides high torque output, smooth operation, and compact design. The WPDA model, along with WPXS, WPDO, and WPDX, incorporates a motor flange input, allowing direct connection to a motor without contacting transmission components, enhancing user safety by eliminating the need for a safety cover.

With input motor power ranging from 0.18kW to 15kW and a maximum input speed of 1500 r/min, it ensures optimal performance. Exceeding this speed may reduce the reducer’s service life. The WPDA worm gearbox’s robust construction, high reduction ratios, and reliable operation make it ideal for conveyors, packaging machines, and other equipment requiring precise speed control and high torque. Its flange input design simplifies installation and maintenance.

WPDA Worm Gear Reducer Specifications

| Product Name: | WPDA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPDA |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60,200,300,400,500,600,800,900 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.06KW~15KW |

| IEC Flange: | 56B14, 63B14, 63B5, 63B5, 71B14,80B14, etc. |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

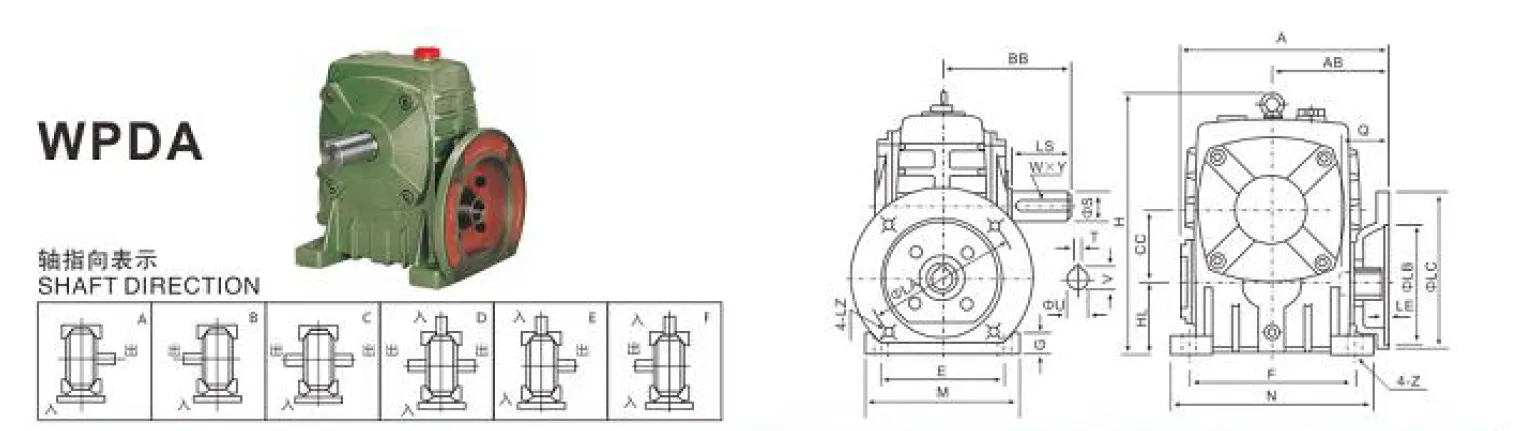

WPDA Worm Gearbox Dimensions

| Size | Power (kw) | Ratio | A | AB | BB | CC | H | HL | M | N | E | F | G | Z |

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 135 | 75 | 74 | 40 | 138 | 40 | 90 | 100 | 70 | 80 | 13 | 10 |

| 50 | 0.18 | 151 | 83 | 97 | 50 | 176 | 50 | 120 | 140 | 95 | 110 | 15 | 12 | |

| 60 | 0.37 | 167 | 91 | 112 | 60 | 204 | 60 | 130 | 150 | 105 | 120 | 20 | 12 | |

| 70 | 0.37 | 200 | 109 | 131 | 70 | 236 | 70 | 150 | 190 | 115 | 150 | 20 | 15 | |

| 80 | 0.75 | 202 | 111 | 131 | 70 | 236 | 70 | 150 | 190 | 115 | 150 | 20 | 15 | |

| 1.5 | 225 | 125 | 142 | 80 | 268 | 80 | 170 | 220 | 135 | 180 | 20 | 15 | ||

| 120 | 2.2 | 280 | 148 | 169 | 100 | 336 | 100 | 190 | 270 | 155 | 220 | 25 | 15 | |

| 3.0 | 333 | 181 | 190 | 120 | 430 | 120 | 230 | 320 | 180 | 260 | 30 | 18 | ||

| 135 | 4.0 | 375 | 202 | 210 | 135 | 480 | 135 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 147 | 4.0 | 415 | 235 | 210 | 147 | 460 | 123 | 250 | 350 | 200 | 280 | 32 | 18 | |

| 175 | 5.5 | 448 | 247 | 252 | 155 | 531 | 135 | 275 | 390 | 220 | 320 | 35 | 21 | |

| 7.5 | 481 | 262 | 255 | 175 | 600 | 160 | 310 | 430 | 250 | 350 | 40 | 21 | ||

| 200 | 11.0 | 543 | 285 | 319 | 200 | 666 | 175 | 360 | 480 | 290 | 390 | 40 | 24 | |

| 250 | 11.0 | 615 | 330 | 385 | 250 | 800 | 200 | 460 | 560 | 380 | 480 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 5 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 40 | 17 | 5×3 | 8 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 50 | 22 | 7×4 | 11 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 60 | 28 | 7×4 | 17 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 60 | 28 | 7×4 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 65 | 32 | 10×4.5 | 22 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 75 | 38 | 10×4.5 | 38 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 45 | 12×4.5 | 64 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 85 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 105 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 60 | 18×7 | 118 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 65 | 18×7 | 165 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 125 | 70 | 20×7.5 | 236 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 155 | 90 | 25×9 | 396 |

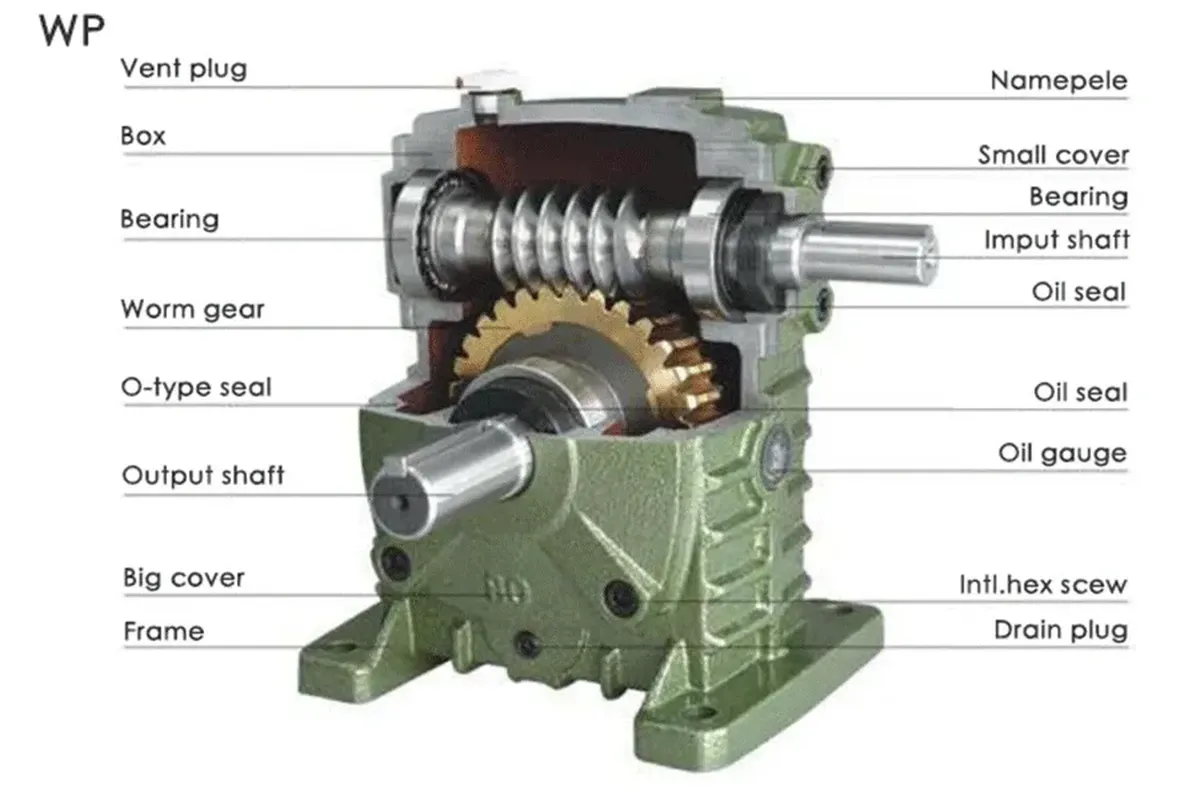

WPDA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPDA Worm Gear Reducer Advantages

- High Torque Output

The WPDA worm gear reducer delivers exceptional torque for heavy-duty applications like conveyors and mixers. Its worm gear design ensures efficient power transmission, enabling reliable performance under high loads while maintaining smooth operation and precise speed control in industrial settings. - Compact and Space-Saving Design

The WPDA worm gearbox’s compact structure allows installation in tight spaces without sacrificing performance. Its efficient layout integrates seamlessly with machinery, making it ideal for applications where space is limited, such as packaging equipment or small-scale automation systems, while ensuring durability and functionality. - Safe Flange Input Connection

Featuring a motor flange input, the WPDA worm reducer gearbox connects directly to the motor, avoiding contact with transmission parts. This design eliminates the need for a safety cover, enhancing user safety and simplifying maintenance in environments where operator protection is critical. - Wide Power Range Versatility

With input motor power from 0.18kW to 15kW, the WPDA worm gear speed reducer accommodates diverse applications, from light-duty tasks to heavy industrial processes. This versatility ensures compatibility with various motor types, providing flexibility for industries like manufacturing, agriculture, and material handling. - Smooth and Quiet Operation

The WPDA worm drive gearbox’s worm gear mechanism ensures low-noise performance, reducing workplace disturbances. Its smooth operation minimizes vibrations, enhancing the lifespan of connected machinery and improving efficiency in applications requiring consistent, quiet performance, such as food processing or automated assembly lines. - High Reduction Ratios

Offering high gear reduction ratios, the WPDA worm drive reduction gearbox provides precise speed control for applications requiring low output speeds and high torque. This capability is essential for tasks like lifting equipment or conveyor systems, ensuring accurate performance and energy efficiency in demanding industrial environments.

WPDA Worm Drive Gearbox Parts

- Worm Gear

The worm gear is a critical component that meshes with the worm shaft to achieve speed reduction and torque transmission. Made from durable materials like bronze, it ensures smooth operation, high load capacity, and resistance to wear during prolonged use. - Worm Shaft

The worm shaft is a helical gear that drives the worm gear, creating the unique sliding motion of the worm drive. It is typically constructed from hardened steel for strength and precision, ensuring efficient power transfer and reduced friction. - Housing (Gearbox Casing)

The housing encases all internal components, protecting them from dust, debris, and environmental damage. Crafted from high-quality cast iron or aluminum alloys, it provides structural stability, reduces vibration, and dissipates heat effectively to enhance overall performance. - Output Shaft

The output shaft transfers the reduced speed and amplified torque to the connected machinery. Designed for high precision and durability, it ensures reliable operation under varying loads and supports the seamless transfer of motion without compromising efficiency. - Sealing and Bearings

High-quality seals and bearings are used to reduce friction and prevent lubricant leakage. They enhance the system’s durability by ensuring smooth rotation of internal components, minimizing wear, and protecting the gearbox from contaminants like dust and moisture. - Flange Input Connection

The flange input connection allows direct attachment to an electric motor, eliminating the need for additional coupling mechanisms. This design simplifies installation, ensures secure motor integration, and optimizes alignment for efficient power transmission into the gearbox.

WPDA Worm Gear Speed Reducer Applications

- Conveyor Systems

WPDA worm gear speed reducers are widely used in conveyor systems for industries like manufacturing, logistics, and mining. They provide precise speed control and high torque output, ensuring smooth and reliable operation, even when handling heavy loads over extended periods. - Material Handling Equipment

In material handling equipment such as cranes, hoists, and forklifts, WPDA reducers deliver enhanced torque and stability. Their compact design and durability make them essential for lifting, transporting, and positioning heavy materials in industrial and construction environments. - Mixers and Agitators

These worm gear reducers are ideal for mixers and agitators in industries such as food processing, pharmaceuticals, and chemicals. They ensure consistent rotational speeds and torque, enabling efficient mixing of ingredients or materials without fluctuations or mechanical strain. - Packaging Machinery

WPDA speed reducers are extensively used in packaging machines for applications like sealing, labeling, and filling. Their ability to provide accurate speed reduction and smooth motion ensures precise and efficient packaging operations, critical in high-volume production lines. - Elevators and Lifting Platforms

Worm gear reducers are utilized in elevators and lifting platforms for their ability to handle high loads while maintaining safety and reliability. Their smooth operation and torque control ensure stable lifting and lowering, even under heavy-duty usage conditions. - Agricultural Machinery

WPDA gear reducers are frequently used in agricultural equipment like irrigation systems, plows, and harvesters. Their robust construction and ability to withstand harsh environments ensure efficient power transmission, enabling consistent performance in demanding outdoor settings.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Food and Beverage Industry |

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Chemical Industry |

Additional information

| Edited by | Yjx |

|---|