CMN-NMRV063 Worm Gear Reducers/Worm Gearbox

The CMN-NMRV063 worm gear reducer (commonly referred to as a worm gearbox) is a compact and efficient mechanical device designed for power transmission and torque reduction in various industrial applications. These gear reducers utilize a worm gear and a worm wheel system to achieve high torque output with a low rotational speed, making them ideal for scenarios requiring precise motion control and heavy load handling. The “063” in the name refers to the specific size of the gearbox, indicating its center distance in millimeters (63 mm), which determines its capacity and physical dimensions.

The CMN-NMRV063 worm gear reducer (commonly referred to as a worm gearbox) is a compact and efficient mechanical device designed for power transmission and torque reduction in various industrial applications. These gear reducers utilize a worm gear and a worm wheel system to achieve high torque output with a low rotational speed, making them ideal for scenarios requiring precise motion control and heavy load handling. The "063" in the name refers to the specific size of the gearbox, indicating its center distance in millimeters (63 mm), which determines its capacity and physical dimensions.

CMN-NMRV063 worm gearboxes are characterized by their compact design, lightweight aluminum alloy housing, and excellent thermal conductivity, which ensures durability and efficient heat dissipation. They also offer high shock resistance, minimal noise, and smooth operation. With ratios ranging from 5:1 to 100:1 or higher, these gearboxes are widely used in conveyor systems, automation equipment, packaging machines, and other machinery requiring reliable speed reduction. Additionally, they often feature a modular design, allowing for easy integration with motors and adaptability to various mounting positions.

CMN-NMRV063 Worm Gearbox Specifications

| Type | CMN-NMRV063 Worm Gearbox/ Worm Gear Speed Reducer |

| Model | CMN-NMRV063 |

| Reduction Ratio | 5,7.5,10,15,20,25,30,40,50,60,80,100 |

| Flange | FA / FL or as per your demands |

| Matching Motor | 0.06KW~15KW |

| Material | Die-casting Aluminum Alloy |

| Color | Blue /Silver Grey /Customized |

| Flange Standard | PAM / IEC |

| Accessories | Shaft, Flange, Torque arm, etc |

| Lubricant | Synthetic Oil or Worm Gear Oil |

| Usage | Machinery of food stuff, ceramics, chemicals, packing, dyeing, wood working, glass industries, etc |

| Note: 1) Please choose from the above specifications. 2) If the above options can not meet your demands, please send us your requirements(ratio, flange, mounting, application, or a picture of your old one), and we will recommond a suitable type. | |

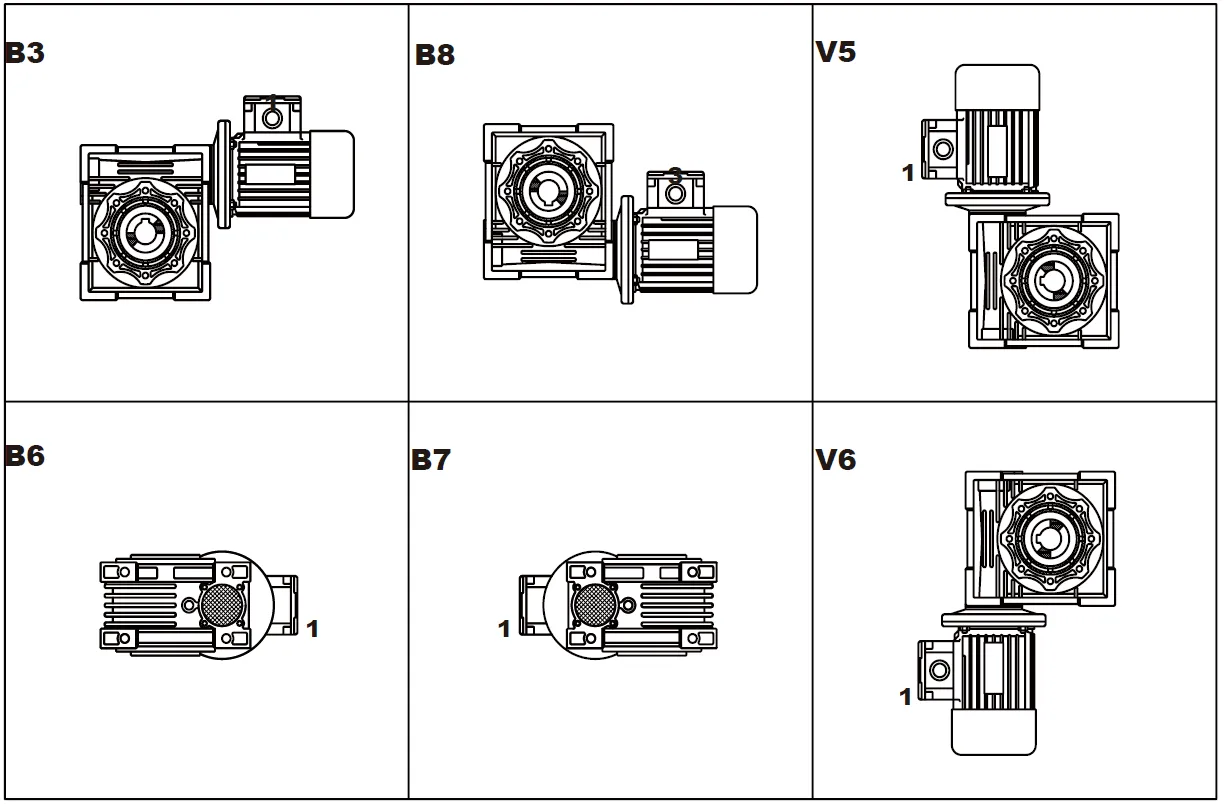

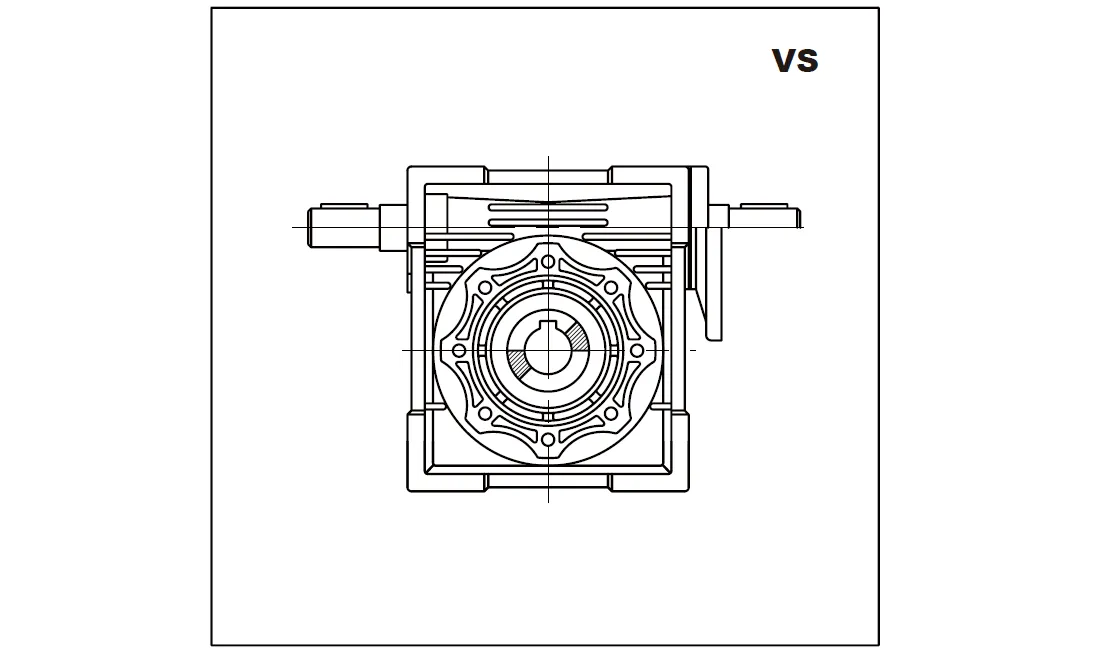

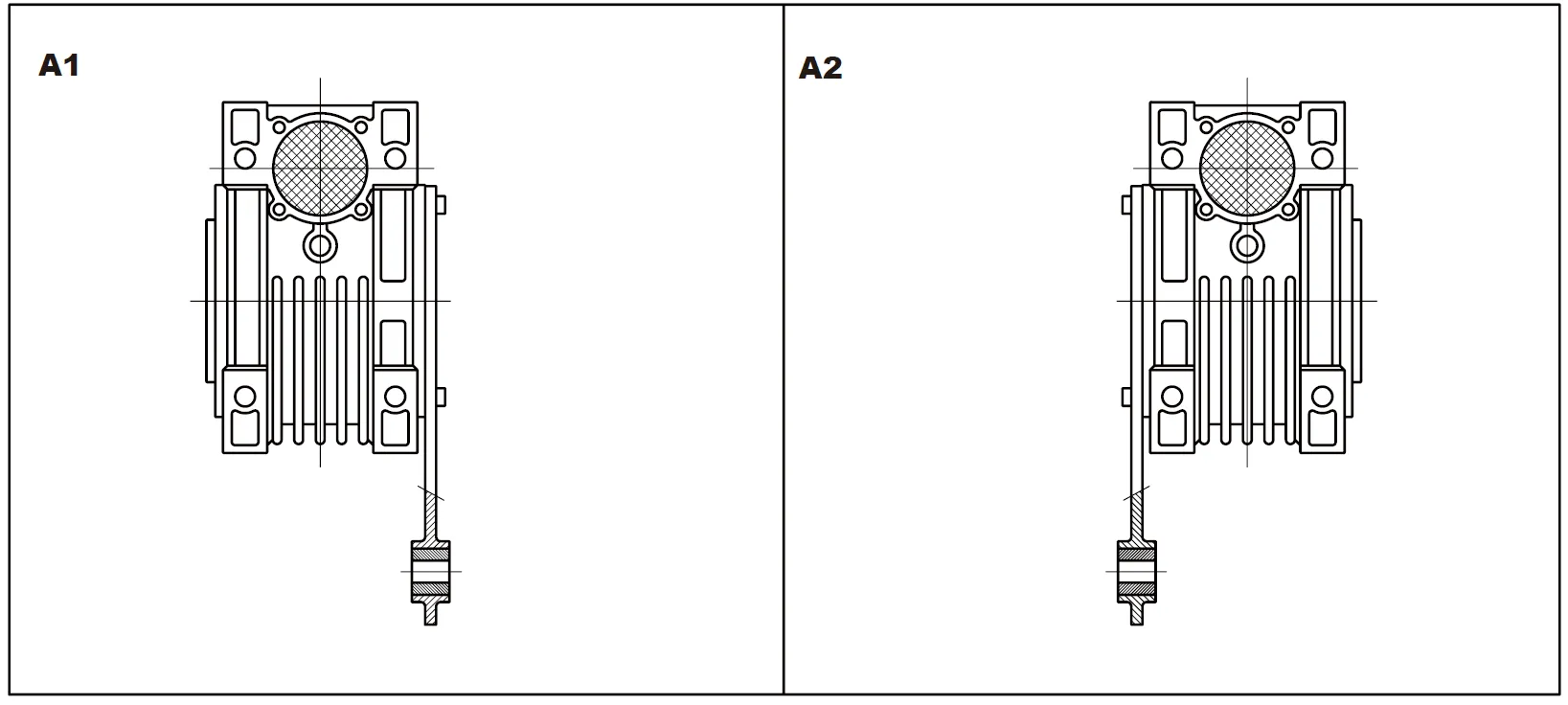

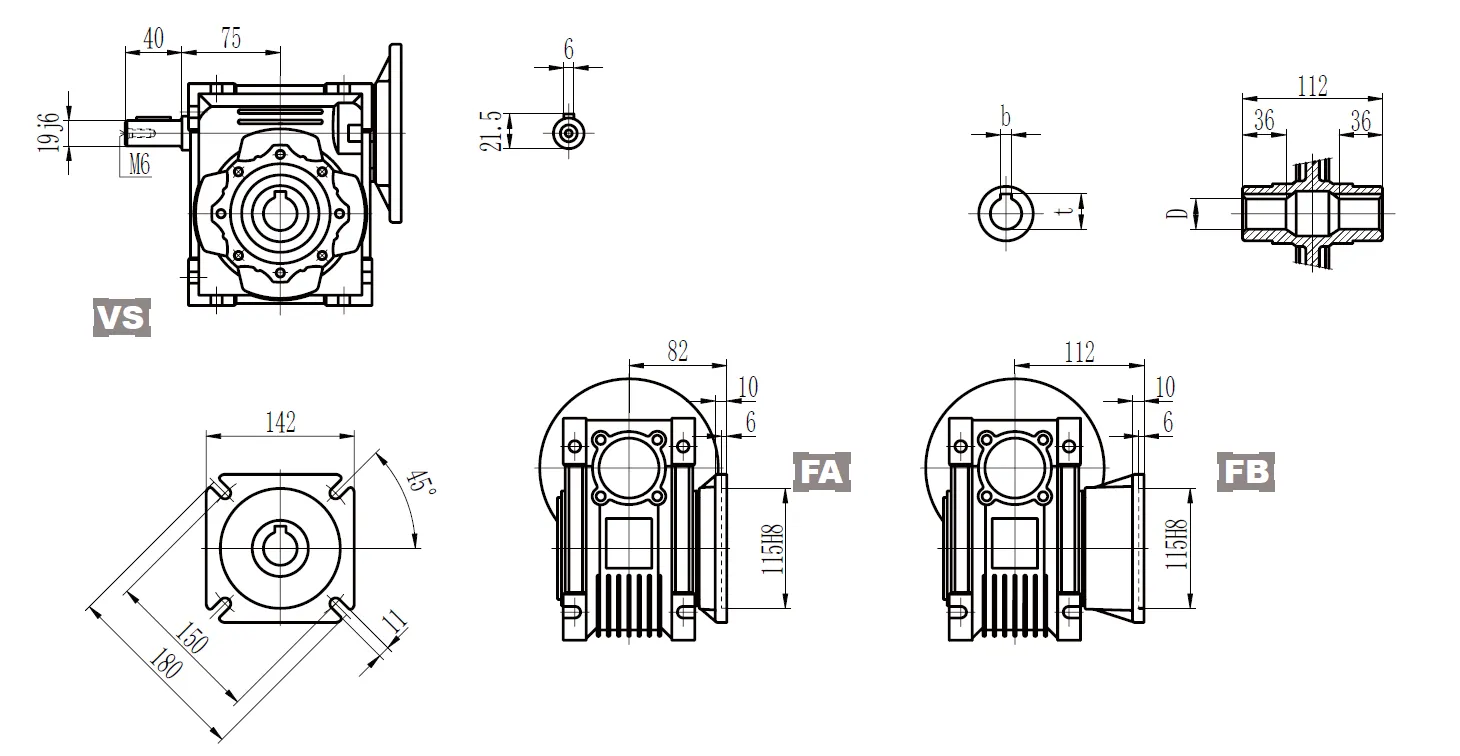

Mounting Position

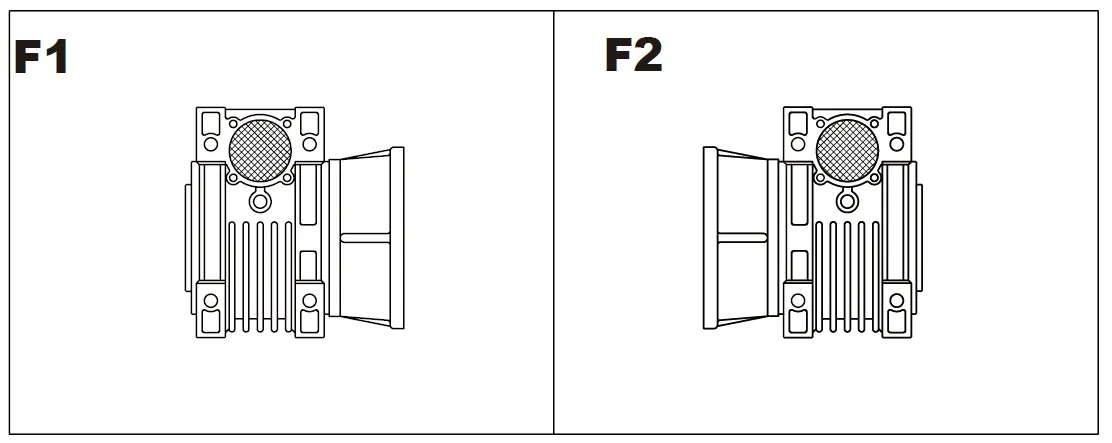

Flange F-FL

Position of Terminal Box

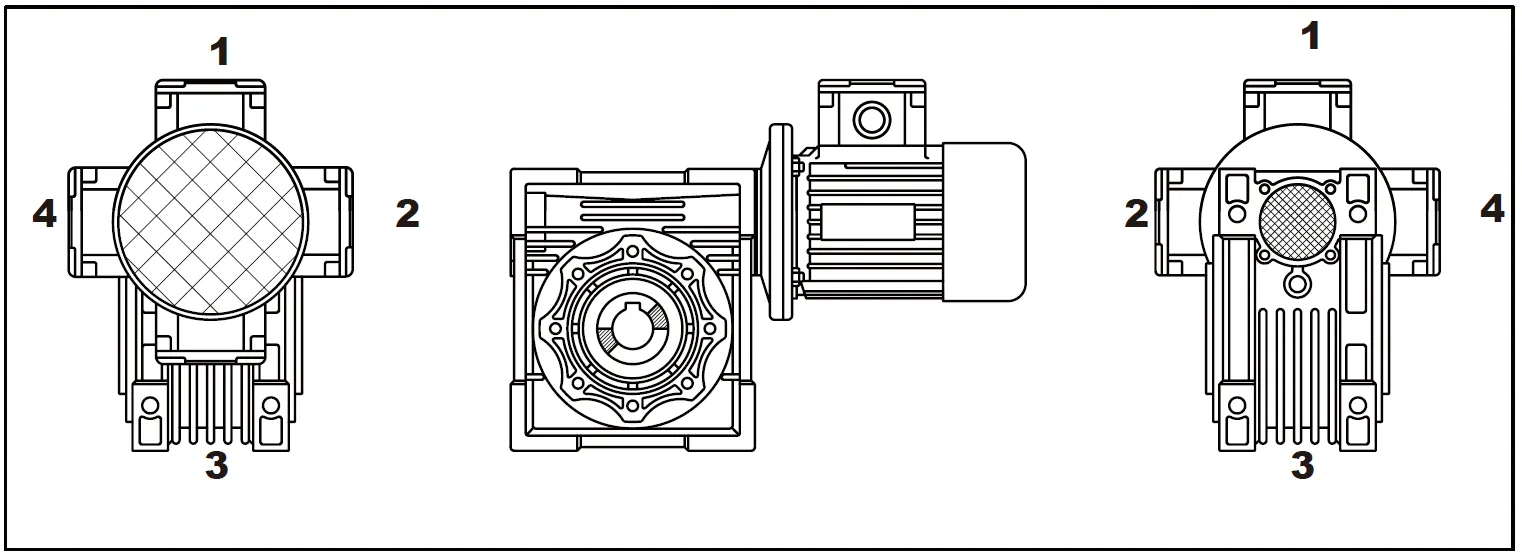

Position of Output Shaft

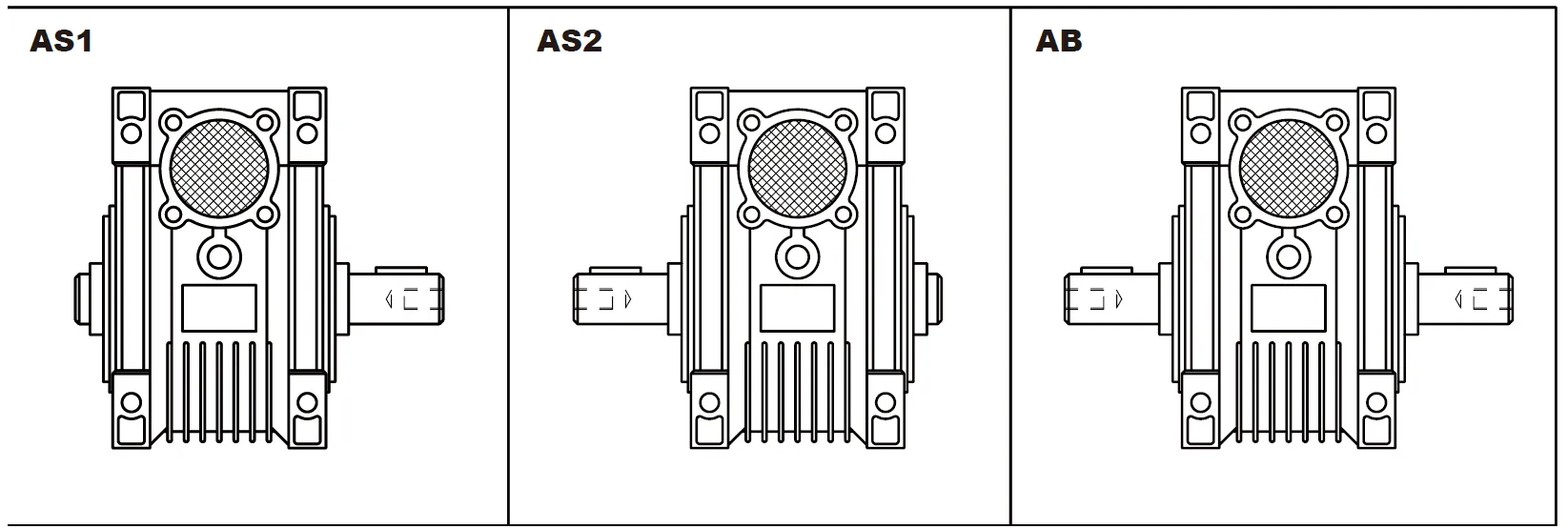

Double Extension Worm Shaft

Position of Torque Arm

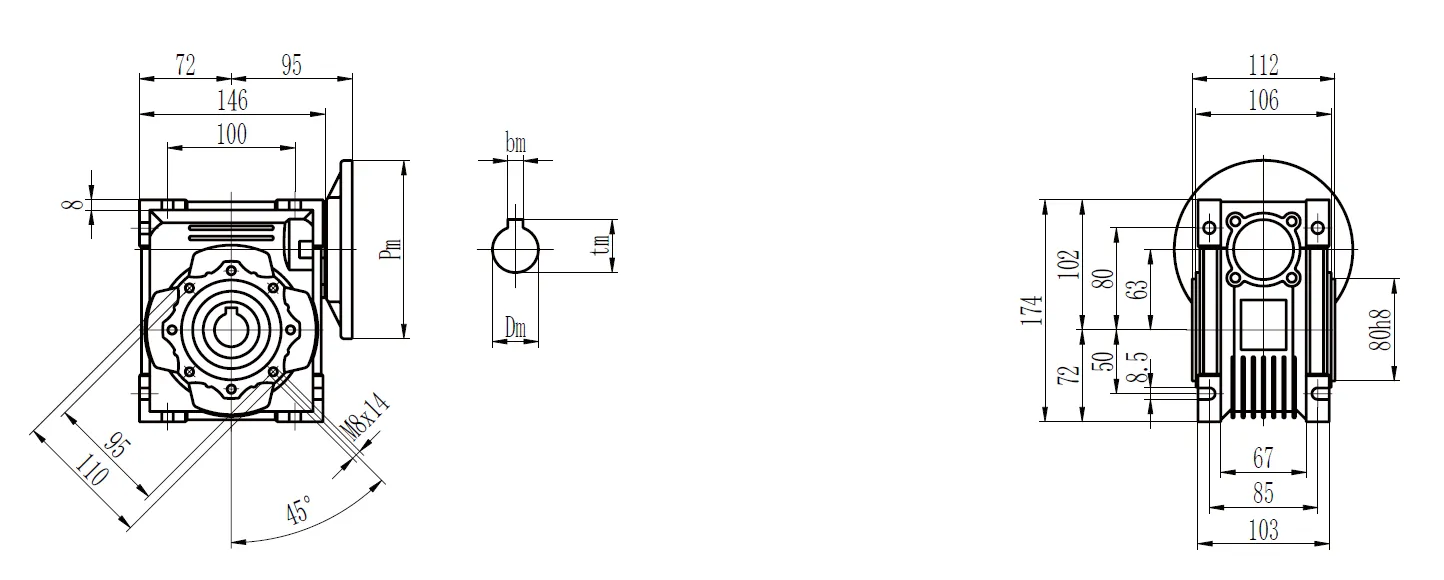

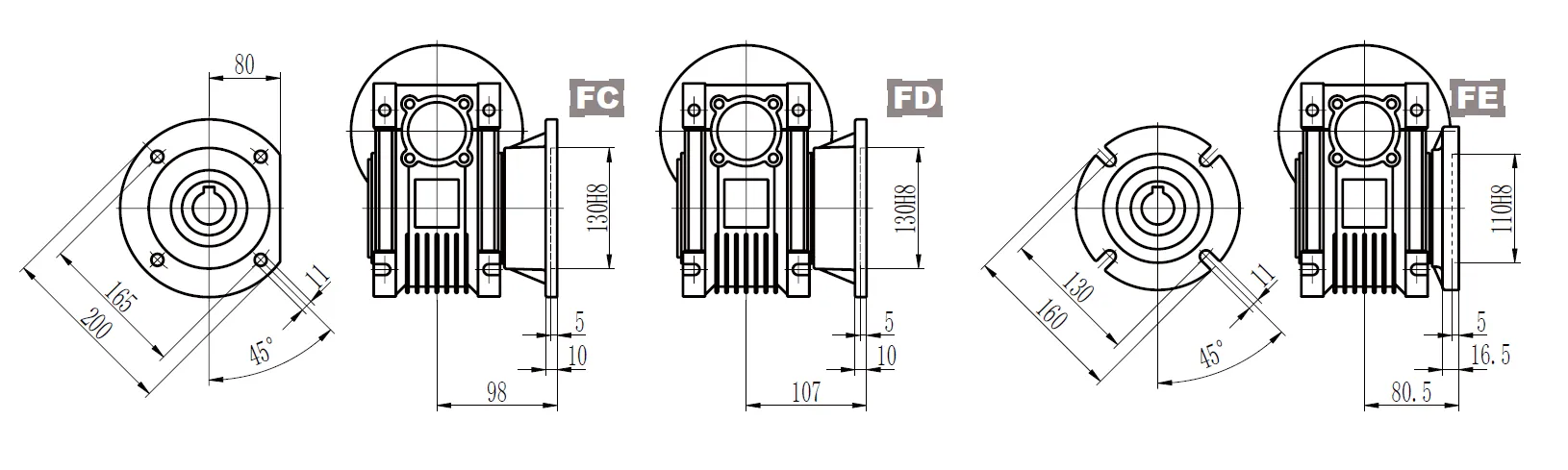

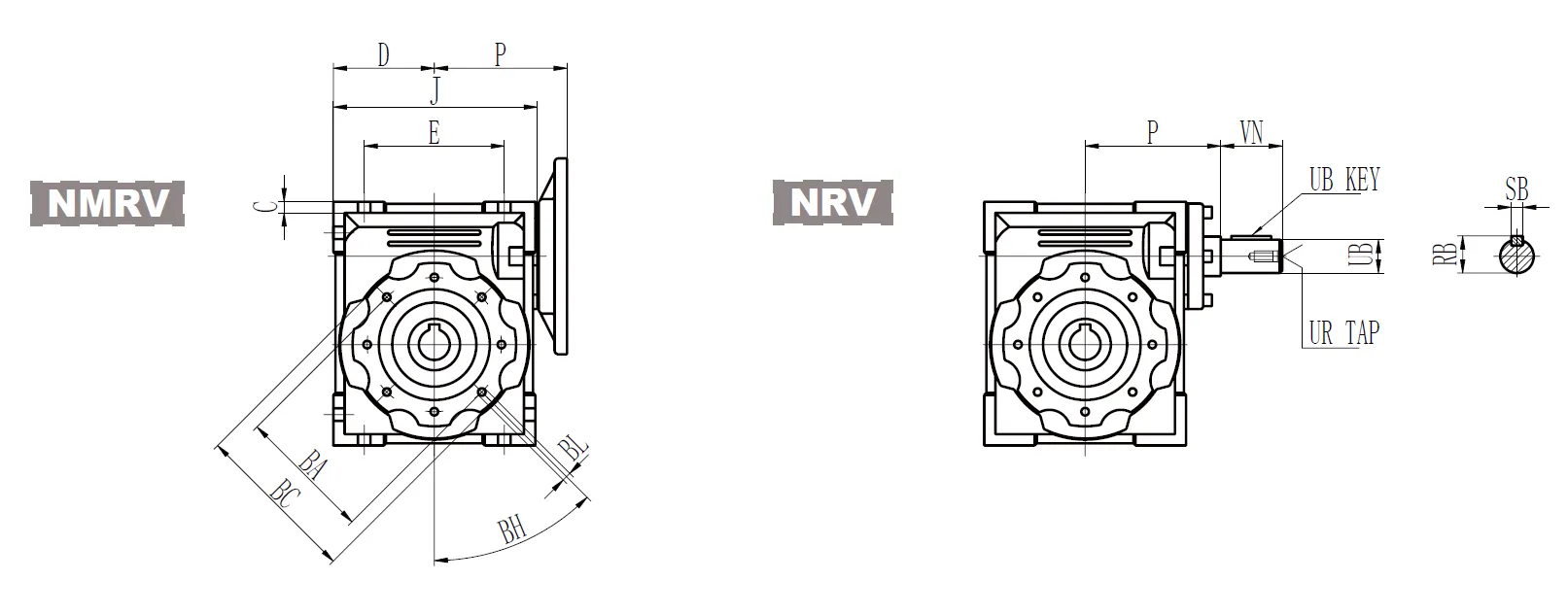

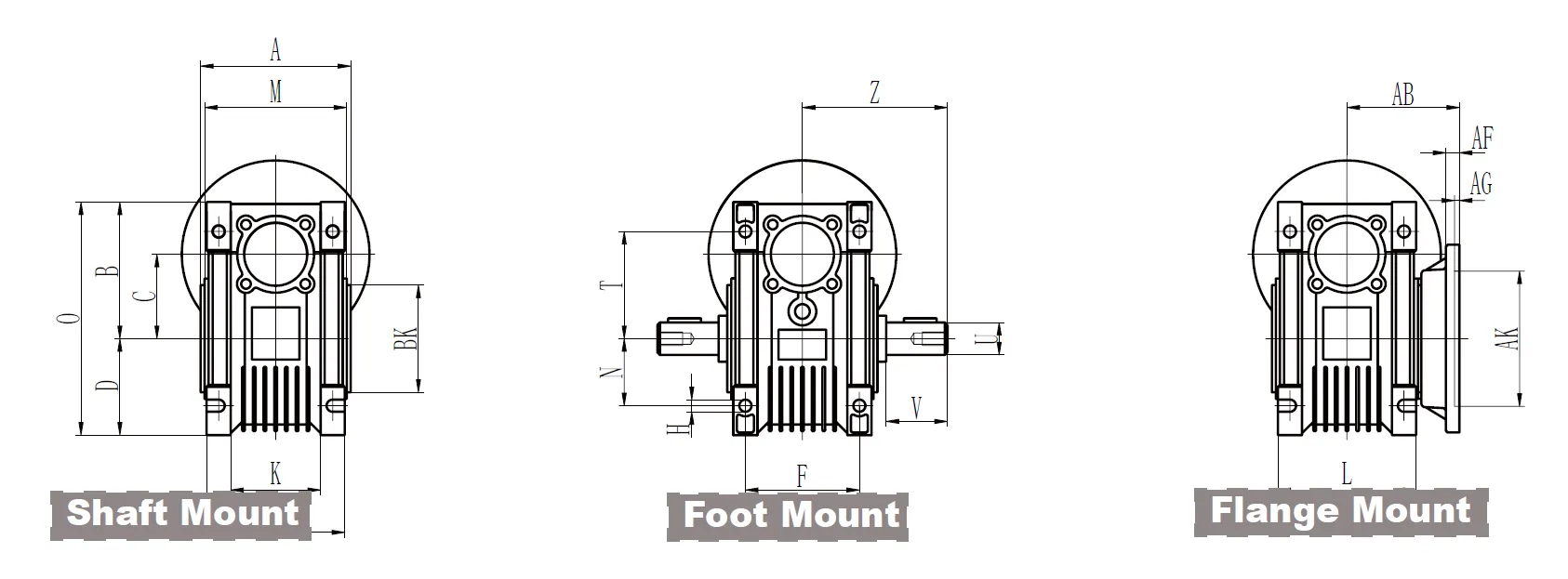

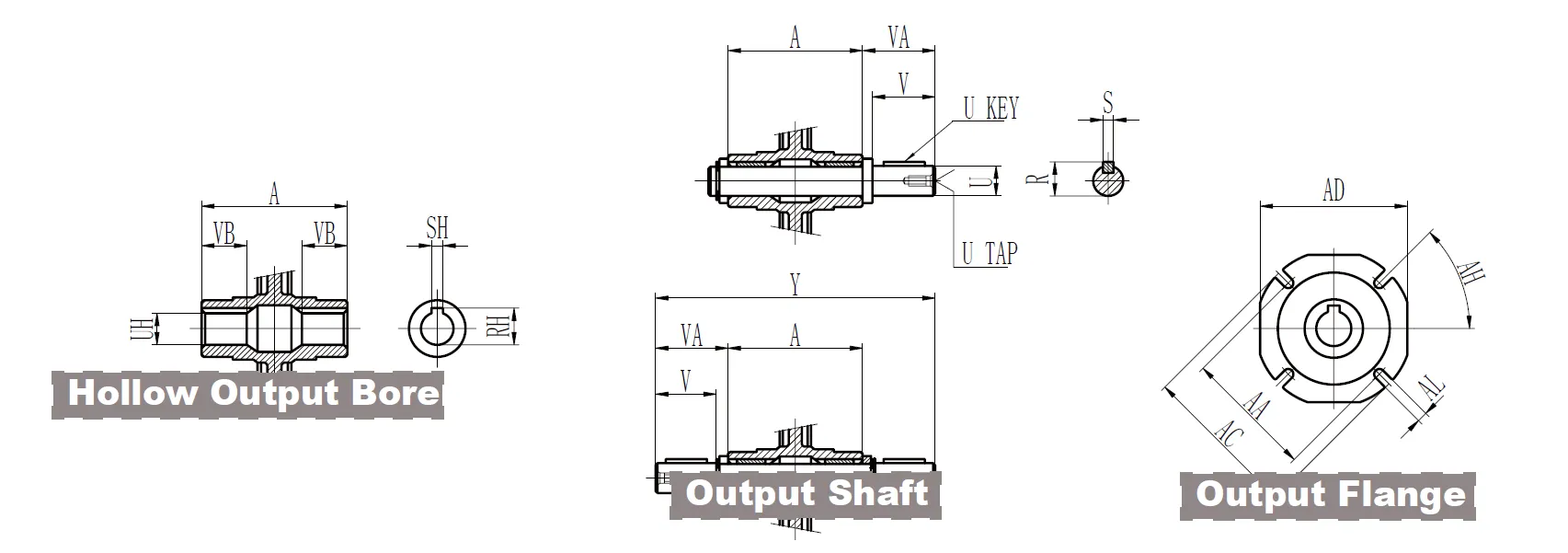

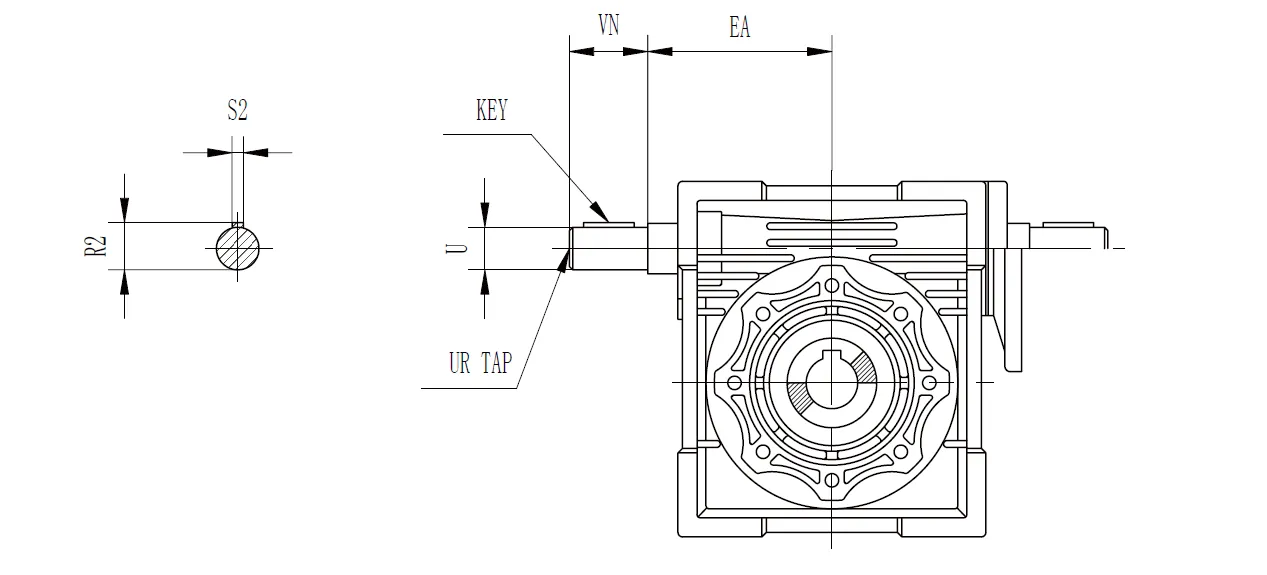

CMN-NMRV063 Worm Gear Reducer Dimensions

CMN-NMRV Worm Gear Reducer Dimensions

CMN-NMRV Inch Series

| Hollow Output Bore | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| RH | 0.71 | 0.84 | 1.12 | 1.24 | 1.37 | 1.52 | 1.8 | 1.93 | |

| SH | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| UH | 0.625+0.001 0 | 0.75+0.001 0 | 1+0.001 0 | 1.125+0.001 0 | 1.25+0.001 0 | 1.375+0.001 0 | 1.625+0.001 0 | 1.750 | |

| VB | 0.83 | 1.14 | 1.28 | 1.42 | 1.56 | 1.77 | 1.97 | 2.24 | |

| Output Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| R | 0.7 | 0.83 | 1.11 | 1.23 | 1.36 | 1.51 | 1.79 | 1.92 | |

| S | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| U | 0.6250 -0.0005 | 0.750 -0.0005 | 10 -0.0005 | 0 -0.0005 | 1.250 -0.0005 | 1.3750 -0.0005 | 1.6250 -0.0005 | 1.750 -0.0005 | |

| U KEY | 0.1875x1.125 | 0.1875x1.5 | 0.25x1.5 | 0.25x1.875 | 0.25x2.25 | 0.3125x2.5 | 0.375x2.75 | 0.375x2.75 | |

| UT | 1/4-20 | 1/4-20 | 3/8-16 | 3/8-16 | 1/2-13 | 1/2-13 | 5/8-11 | 5/8-11 | |

| V | 1.57 | 1.97 | 1.97 | 2.36 | 2.76 | 3.15 | 3.54 | 3.54 | |

| VA | 1.67 | 2.09 | 2.11 | 2.5 | 2.89 | 3.33 | 3.72 | 3.74 | |

| Y | 5.82 | 7.25 | 7.84 | 9.41 | 10.5 | 12.17 | 13.54 | 14.17 | |

| CMN-NMRV | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| A | 2.48 | 3.07 | 3.62 | 4.41 | 4.72 | 5.51 | 6.1 | 6.69 |

| B | 2.24 | 2.81 | 3.31 | 4.02 | 4.69 | 5.31 | 6.59 | 7.38 |

| BA | 2.56 | 2.95 | 3.35 | 3.74 | 4.53 | 5.12 | 6.5 | 8.46 |

| BC | 2.95 | 3.43 | 3.94 | 4.33 | 5.51 | 6.3 | 7.87 | 9.84 |

| BH | 90 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45° | 45 ° |

| BK | 2.165 0 -0.0018 | 2.362 0 -0.0018 | 2.756 0 -0.0018 | 3.15 0 -0.0021 | 3.74 0 -0.0021 | 4.331 0 -0.0021 | 5.118 0 -0.0025 | 7.087 0 -0.0025 |

| BL | M6x11 | M6x10 | M8x10 | M8x14 | M8x14 | M10x18 | M10x18 | M12x21 |

| C | 1.18 | 1.57 | 1.97 | 2.48 | 2.95 | 3.54 | 4.33 | 5.12 |

| D | 1.57 | 1.97 | 2.36 | 2.83 | 3.39 | 4.06 | 5.02 | 5.81 |

| E | 2.13 | 2.76 | 3.15 | 3.94 | 4.72 | 5.51 | 6.69 | 7.87 |

| F | 1.73 | 2.36 | 2.76 | 3.35 | 3.54 | 3.94 | 4.53 | 4.72 |

| G | 0.22 | 0.26 | 0.28 | 0.31 | 0.39 | 0.43 | 0.57 | 0.61 |

| H | 0.26 | 0.26 | 0.33 | 0.33 | 0.45 | 0.51 | 0.55 | 0.63 |

| J | 3.15 | 3.98 | 4.76 | 5.75 | 6.85 | 8.19 | 9.94 | 11.52 |

| K | 1.26 | 1.69 | 1.93 | 2.64 | 2.83 | 2.91 | - | - |

| L | 2.2 | 2.8 | 3.35 | 4.06 | 4.41 | 5.12 | 5.67 | 6.1 |

| M | 2.28 | 2.87 | 3.43 | 4.17 | 4.49 | 5.28 | 5.83 | 6.38 |

| N | 1.06 | 1.38 | 1.57 | 1.97 | 2.36 | 2.76 | 3.35 | 3.94 |

| O | 3.82 | 4.78 | 5.67 | 6.85 | 8.07 | 9.37 | 11.61 | 13.19 |

| P | 2.64 | 3.15 | 3.54 | 4.13 | 4.96 | 5.63 | 6.81 | 7.6 |

| Q | 0.83 | 2.36 | 2.91 | 3.54 | 4.13 | 4.92 | 5.59 | 6.38 |

| T | 1.73 | 2.17 | 2.52 | 3.15 | 3.66 | 4.02 | 4.92 | 5.51 |

| Z | 2.91 | 3.63 | 3.92 | 4.71 | 5.25 | 6.09 | 6.77 | 7.09 |

| Output Flange | AA | AB | AC | AD | AF | AG | AH | AK | AL | ||

| 030 | FA | 2.68 | 2.15 | 3.15 | 2.76 | 0.24 | 0.16 | 45° | 1.969 | +0.0015 0 | 0.26 |

| 040 | FA | 2.95 | 2.64 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 | 0.35 |

| 0 | |||||||||||

| FB | 2.95 | 3.82 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 0 | 0.35 | |

| FC | 4.53 | 3.15 | 5.51 | - | 0.35 | 0.2 | 45° | 3.74 | +0.0021 0 | 0.37 | |

| FD | 3.94 | 2.28 | 4.72 | - | 0.47 | 0.2 | 45° | 3.15 | +0.0018 | 0.35 | |

| 0 | |||||||||||

| 050 | FA | 3.35 | 3.54 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 | 0.43 |

| 0 | |||||||||||

| FB | 3.35 | 4.72 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 0 | 0.43 | |

| FC | 5.12 | 3.5 | 6.3 | - | 0.39 | 0.2 | 45° | 4.331 | +0.0021 0 | 0.37 | |

| FD | 4.53 | 2.83 | 5.51 | - | 0.57 | 0.2 | 45° | 3.543 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 063 | FA | 4.13 | 3.23 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 |

| 0 | |||||||||||

| FB | 5.91 | 4.41 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| FC | 6.5 | 3.86 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.5 | 4.21 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 | 0.43 | |

| 0 | |||||||||||

| FE | 5.12 | 3.17 | 6.3 | - | 0.65 | 0.2 | 45° | 4.331 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 075 | FA | 6.5 | 4.37 | 7.87 | 6.69 | 0.51 | 0.24 | 45° | 5.118 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 5.12 | 3.54 | 6.3 | - | 0.51 | 0.24 | 45° | 4.331 | +0.0021 | 0.55 | |

| 0 | |||||||||||

| 090 | FA | 6.89 | 4.37 | 8.27 | 8.27 | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 8.46 | 4.8 | 9.84 | - | 0.71 | 0.24 | 45° | 7.087 | +0.0025 0 | 0.55 | |

| FC | 6.5 | 4.33 | 7.87 | - | 0.67 | 0.24 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.89 | 5.94 | 8.27 | - | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 110 | FA | 9.06 | 5.16 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 9.06 | 7.09 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 130 | FA | 10.04 | 5.51 | 12.6 | 11.42 | 0.59 | 0.24 | 22.5° | 7.087 | +0.0025 0 | 0.63 |

| Input Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| SB | 0.094 | 0.125 | 0.188 | 0.188 | 0.188 | 0.188 | 0.25 | 0.25 | |

| RB | 0.42 | 0.55 | 0.7 | 0.83 | 0.96 | 0.96 | 1.24 | 1.36 | |

| UB | 0.3750 -0.0005 | 0.50 -0.0005 | 0.6250 -0.0005 | 0.750 -0.0005 | 0.8750 -0.0005 | 0.8750 -0.0005 | 1.1250 -0.0005 | 1.250 -0.0005 | |

| UB KEY | 0.094x0.875 | 0.125x0.875 | 0.1875x1.125 | 0.1875x1.5 | 0.1875x1.875 | 0.1875x1.875 | 0.25x2.25 | 0.25x2.5 | |

| UR | - | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 3/8-16 | 1/2-13 | |

| VN | 1.18 | 1.18 | 1.58 | 1.97 | 2.36 | 2.36 | 2.76 | 3.15 | |

High Speed Extension Shaft Dimensions

| CMN-NMRV | EA | U | VN | UR | S2 | R2 | KEY | |

| Length | Square | |||||||

| 030 | 1.772 | 0.3750 -0.0005 | 1.18 | - | 0.093 | 0.42 | 0.875 | 0.094 |

| 040 | 2.087 | 0.50 -0.0005 | 1.18 | 1/4-20 | 0.13 | 0.55 | 0.875 | 0.125 |

| 050 | 2.52 | 0.6250 -0.0005 | 1.58 | 1/4-20 | 0.19 | 0.7 | 1.125 | 0.188 |

| 063 | 2.953 | 0.750 -0.0005 | 1.97 | 1/4-20 | 0.19 | 0.83 | 1.5 | 0.188 |

| 075 | 3.543 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 090 | 4.252 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 110 | 5.315 | 1.1250 -0.0005 | 2.76 | 3/8-16 | 0.25 | 1.24 | 2.25 | 0.25 |

| 130 | 6.102 | 1.250 -0.0005 | 3.15 | 1/2-13 | 0.25 | 1.36 | 2.5 | 0.25 |

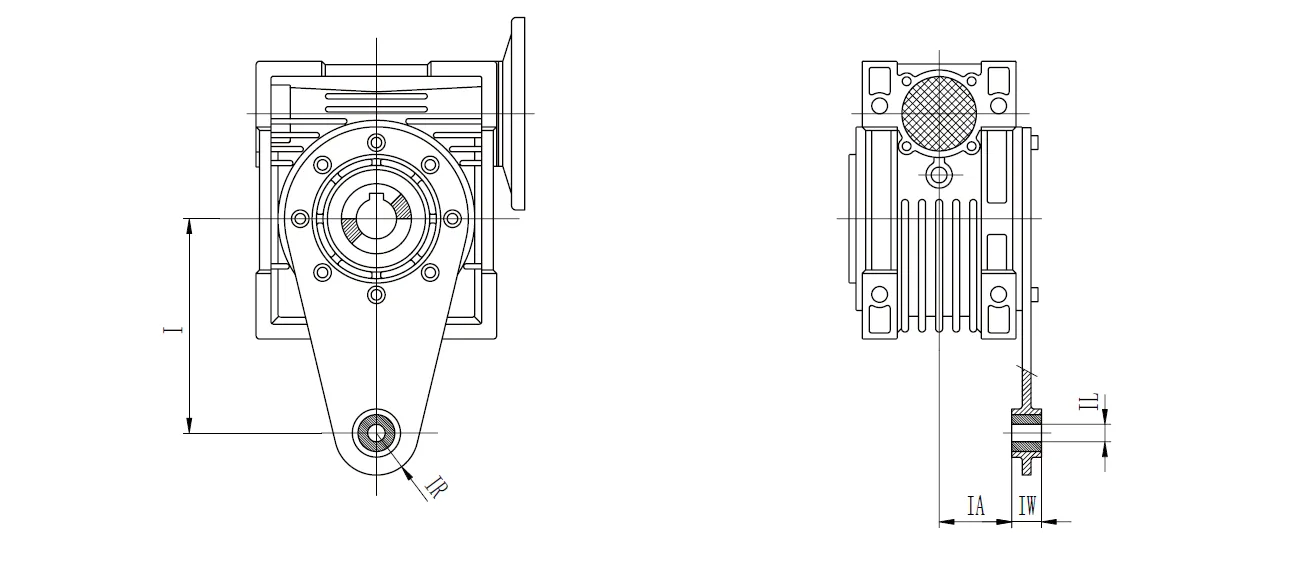

Torque Arm Dimensions

| I | IA | IL | IR | IW | |

| 025 | 2.76 | 0.69 | 0.31 | 0.59 | 0.55 |

| 030 | 3.35 | 0.94 | 0.31 | 0.59 | 0.55 |

| 040 | 3.94 | 1.24 | 0.39 | 0.71 | 0.55 |

| 050 | 3.94 | 1.52 | 0.39 | 0.71 | 0.55 |

| 063 | 5.91 | 1.93 | 0.39 | 0.71 | 0.55 |

| 075 | 7.87 | 1.87 | 0.79 | 1.18 | 0.98 |

| 090 | 7.87 | 2.26 | 0.79 | 1.18 | 0.98 |

| 110 | 9.84 | 2.44 | 0.98 | 1.38 | 1.18 |

| 130 | 9.84 | 2.72 | 0.98 | 1.38 | 1.18 |

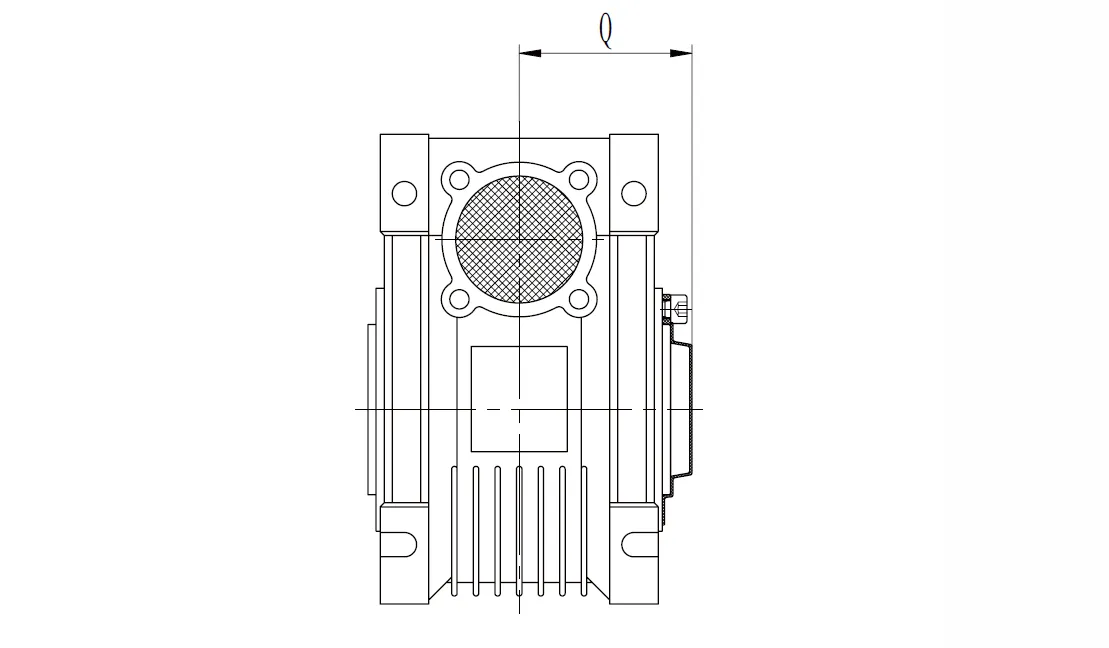

Protective Cover Dimensions

| CMN-NMRV | Q |

| 030 | 1.65 |

| 040 | 1.97 |

| 050 | 2.28 |

| 063 | 2.72 |

| 075 | 2.91 |

| 090 | 3.39 |

| 110 | 3.7 |

| 130 | 4.02 |

NEMA Flange Availability

| CMN-NMRV | NEMA Flange | Input Bore Diameter | Available Ratios | |||||||||||

| 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | |||

| 030 | 48C | 0.5 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 040 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 050 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 063 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 075 | 56C | 0.625 | ● | ● | ● | ● | ||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | |||||||

| 180TC | 1.125 | ● | ● | ● | ||||||||||

| 090 | 56C | 0.625 | ● | ● | ||||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 110 | 140TC | 0.875 | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | |||||||

| 210TC | 1.375 | ● | ● | ● | ● | |||||||||

| 130 | 140TC | 0.875 | ● | ● | ||||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ||||||||

| 210TC | 1.375 | ● | ● | ● | ● | ● | ● | ● | ||||||

CMN-NMRV063 Worm Drive Gearbox Features

- High Torque Output and Efficiency

The CMN-NMRV063 worm drive gearbox delivers exceptional torque amplification through its worm and wheel design, ensuring efficient power transmission. With reduction ratios from 5:1 to 100:1, it provides high torque for demanding applications like conveyors, mixers, and automation systems, maintaining consistent performance under heavy loads. - Compact and Versatile Design

Its compact aluminum alloy housing (or cast iron for heavy-duty models) allows for space-saving installation. The NMRV063 worm gear reducers support universal mounting positions, making it adaptable to various setups in industries such as food processing, textiles, and ceramics, ensuring seamless integration into diverse machinery. - Low Noise and Vibration

Engineered with precision-ground gears, the CMN-NMRV063 worm gear speed reducer operates with minimal noise and vibration, enhancing workplace safety and comfort. This feature is critical for applications requiring quiet performance, such as in packaging or medical equipment, while maintaining smooth and reliable operation over extended periods. - Maintenance-Free Operation

Pre-filled with high-quality synthetic oil, the CMN-NMRV063 worm reducer gearbox requires no regular maintenance, reducing downtime and operational costs. The sealed design prevents oil leakage and contamination, ensuring long-term reliability in harsh environments like chemical plants or outdoor industrial settings, extending the gearbox’s service life. - High Precision and Durability

The worm gear gearbox features high-precision worm gears and robust construction, providing excellent wear resistance and longevity. Designed to handle continuous operation, it withstands high radial and axial loads, making it ideal for heavy-duty applications in manufacturing, mining, and material handling industries. - Compatibility with Multiple Motors

The CMN-NMRV063 worm drive gearbox is compatible with NEMA52, servo, and stepper motors, offering flexibility in motor selection. Its modular flange and coupling design simplify integration into existing systems, enabling precise speed control and torque output for automation, robotics, and other precision-driven applications.

CMN-NMRV063 Worm Gear Reducer Uses

- Food Processing Industry

The CMN-NMRV063 worm gear reducer is widely used in food processing for driving conveyors, mixers, and packaging machines. Its compact design and maintenance-free operation ensure hygienic, reliable performance in environments requiring precise speed control and high torque for consistent production efficiency. - Textile Manufacturing

In textile machinery, the CMN-NMRV063 worm gear drive gearbox powers looms, spinning machines, and winding systems. Its low noise and vibration characteristics enhance workplace comfort, while high torque output ensures smooth operation under varying loads, supporting continuous production in fabric and garment manufacturing processes. - Automation and Robotics

The CMN-NMRV063 worm reducer gearbox is ideal for automation systems and robotics, providing precise speed reduction and torque amplification. Its compatibility with servo and stepper motors enables accurate motion control in robotic arms, assembly lines, and CNC machines, ensuring high precision in automated tasks. - Material Handling Systems

Used in conveyors, hoists, and cranes, the CMN-NMRV063 worm gear reduction gearbox delivers reliable torque for heavy-duty material handling. Its robust construction withstands high radial loads, making it suitable for warehouses, logistics centers, and mining operations where consistent performance under demanding conditions is critical. - Ceramics and Glass Industry

The CMN-NMRV063 worm gearbox motor supports machinery in ceramics and glass production, such as kilns and cutting systems. Its durable housing and low maintenance design ensure reliable operation in high-temperature, dusty environments, providing steady torque for shaping, grinding, and material processing tasks. - Packaging Machinery

In packaging lines, the CMN-NMRV063 worm reduction gearbox drives equipment like fillers, sealers, and labeling machines. Its quiet operation and universal mounting flexibility ensure seamless integration, delivering precise control and high torque for efficient, high-speed packaging processes in industries like pharmaceuticals and consumer goods.

CMN-NMRV063 Worm Gear Reducer Lubrication Tips

- Use the Recommended Lubricant

Always use high-quality, manufacturer-recommended lubricants specifically designed for worm gear reducers. These lubricants typically have anti-wear properties and high viscosity, ensuring proper film strength to reduce friction and wear between the worm and worm wheel during operation. - Maintain Proper Lubricant Levels

Regularly check the lubricant level through the inspection plug or sight glass to ensure it remains within the recommended range. Insufficient lubrication can lead to increased friction and overheating, while overfilling can cause leakage and efficiency loss. - Replace Lubricant Periodically

Change the lubricant at the manufacturer-specified intervals to remove contaminants and maintain optimal performance. Over time, lubricants degrade due to heat and contamination, reducing their effectiveness and increasing the risk of wear and damage to the gearbox. - Monitor Operating Temperature

Excessive heat can degrade the lubricant quickly, reducing its viscosity and effectiveness. Ensure the gearbox operates within its recommended temperature range, and use lubricants with appropriate thermal stability for applications that involve high temperatures or continuous operation. - Inspect for Leaks Regularly

Periodically inspect the gearbox for any signs of lubricant leakage around seals, plugs, or gaskets. Leakage not only reduces lubrication levels but also indicates potential issues with sealing components that need to be addressed to prevent further damage. - Avoid Mixing Different Lubricants

Never mix lubricants of different types, brands, or viscosities, as this can lead to chemical incompatibility and reduced performance. If switching to a different lubricant, thoroughly clean the gearbox to remove any residue of the previous lubricant before refilling.

Additional information

| Edited by | Yjx |

|---|