CMN-NRV-F Worm Gear Reducers/Worm Gearbox

CMN-NRV-F worm gear reducers with input shaft and output flange are specialized mechanical devices designed for the efficient transmission of power and torque in industrial applications. These reducers are part of the worm gear family, which utilizes a worm (screw-like shaft) and a worm wheel (gear) to reduce speed while increasing torque. The CMN-NRV-F series worm gearbox is distinguished by its input shaft and a flange-mounted output configuration, making it ideal for easy integration with machines requiring compact, high-torque solutions.

CMN-NRV-F worm gear reducers with input shaft and output flange are specialized mechanical devices designed for the efficient transmission of power and torque in industrial applications. These reducers are part of the worm gear family, which utilizes a worm (screw-like shaft) and a worm wheel (gear) to reduce speed while increasing torque. The CMN-NRV-F series worm gearbox is distinguished by its input shaft and a flange-mounted output configuration, making it ideal for easy integration with machines requiring compact, high-torque solutions.

The input shaft accepts rotational motion from a motor, while the worm gear mechanism provides smooth, vibration-free operation with high gear reduction ratios. The output flange allows secure mounting to machinery or driven components, ensuring precise alignment and reliable performance. Known for their robust construction, these worm reducer gearboxes are typically constructed from high-quality materials like cast iron or aluminum alloy, ensuring durability and resistance to wear under heavy loads. Common applications include conveyor systems, material handling equipment, packaging machinery, and other industrial automation systems.

CMN-NRV-F Worm Gearbox Specifications

| Model: | CMN-NRV-F 025, 030, 040, 050, 063, 075, 090, 110, 130, 150 |

| Ratio: | 1:5,7.5,10,15,20,25,30,40,50,60,80,100 |

| Color: | Blue, Silver, or On Customer Request |

| Material: | Housing: Die-Cast Aluminum Alloy |

| Worm Gear: Bronze 94# | |

| Worm-20CrMnTi with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft-chromium steel 45# | |

| Packing: | Carton and plywood case |

| Bearing: | C&U Bearing |

| Seal: | NAK, SKF |

| Lubricant: | Synthetic, Mineral |

| Usages: | Industrial Machine: Food Stuff, Ceramics, Chemical, Packing, Dyeing, Wood working, Glass, etc. |

| Warranty: | 12 months |

| Input Power: | 0.06kw, 0.09kw, 0.12kw, 0.18kw, 0.25kw, 0.37kw, 0.55kw, 0.75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

| IEC Flange: | 56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

CMN-NRV-F Worm Gear Reducer Dimensions

| CMN-NRV-F | 025 | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| B | 20 | 20 | 23 | 30 | 40 | 50 | 50 | 60 | 80 |

| D1 | 9 j6 | 9 j6 | 11 j6 | 14 j6 | 19 j6 | 24 j6 | 24 j6 | 28 j6 | 30 j6 |

| G2 | 38 | 51 | 60 | 74 | 90 | 105 | 125 | 142 | 162 |

| G3 | 37 | 45 | 53 | 64 | 75 | 90 | 108 | 135 | 155 |

| I | 25 | 30 | 40 | 50 | 63 | 75 | 90 | 110 | 130 |

| b1 | 3 | 3 | 4 | 5 | 6 | 8 | 8 | 8 | 8 |

| f1 | - | - | - | M6 | M6 | M8 | M8 | M10 | M10 |

| t1 | 10.2 | 10.2 | 12.5 | 16 | 21.5 | 27 | 27 | 31 | 33 |

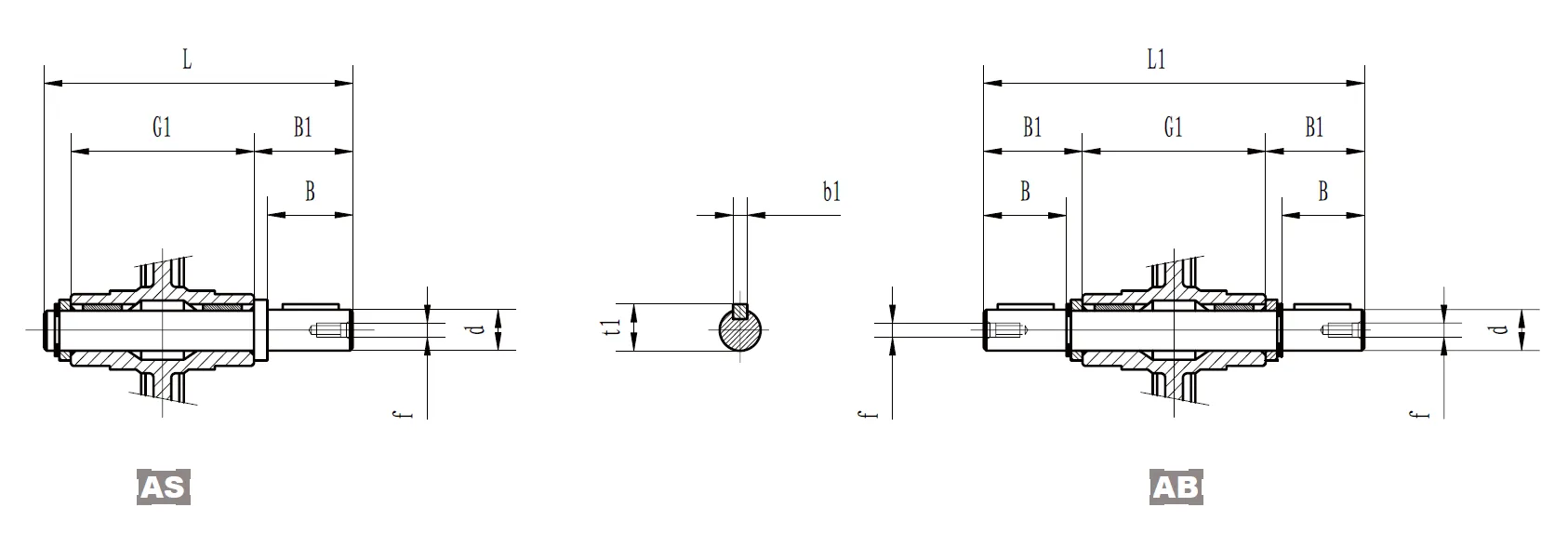

Low Speed Shaft Dimensions

| CMN-NRV-F | d | B | B1 | G1 | L | L1 | f | b1 | t1 |

| 025 | 11g6 (9) | 23 (25) | 25.5 (30) | 50 | 81 (85.5) | 101 | - | 4 (3) | 12.5 (10.2) |

| 030 | 14g6 | 30 | 32.5 | 63 | 102 | 128 | M6 | 5 | 16 |

| 040 | 18h6 | 40 | 43 | 78 | 128 | 164 | M6 | 6 | 20.5 |

| 050 | 25h6 | 50 | 53.5 | 92 | 153 | 199 | M10 | 8 | 28 |

| 063 | 25h6 | 50 | 53.5 | 112 | 173 | 219 | M10 | 8 | 28 |

| 075 | 28h6 | 60 | 63.5 | 120 | 192 | 247 | M10 | 8 | 31 |

| 090 | 35h6 | 80 | 84.5 | 140 | 234 | 309 | M12 | 10 | 38 |

| 110 | 42h6 | 80 | 84.5 | 155 | 249 | 324 | M16 | 12 | 45 |

| 130 | 45h6 | 80 | 85 | 170 | 265 | 340 | M16 | 14 | 48.5 |

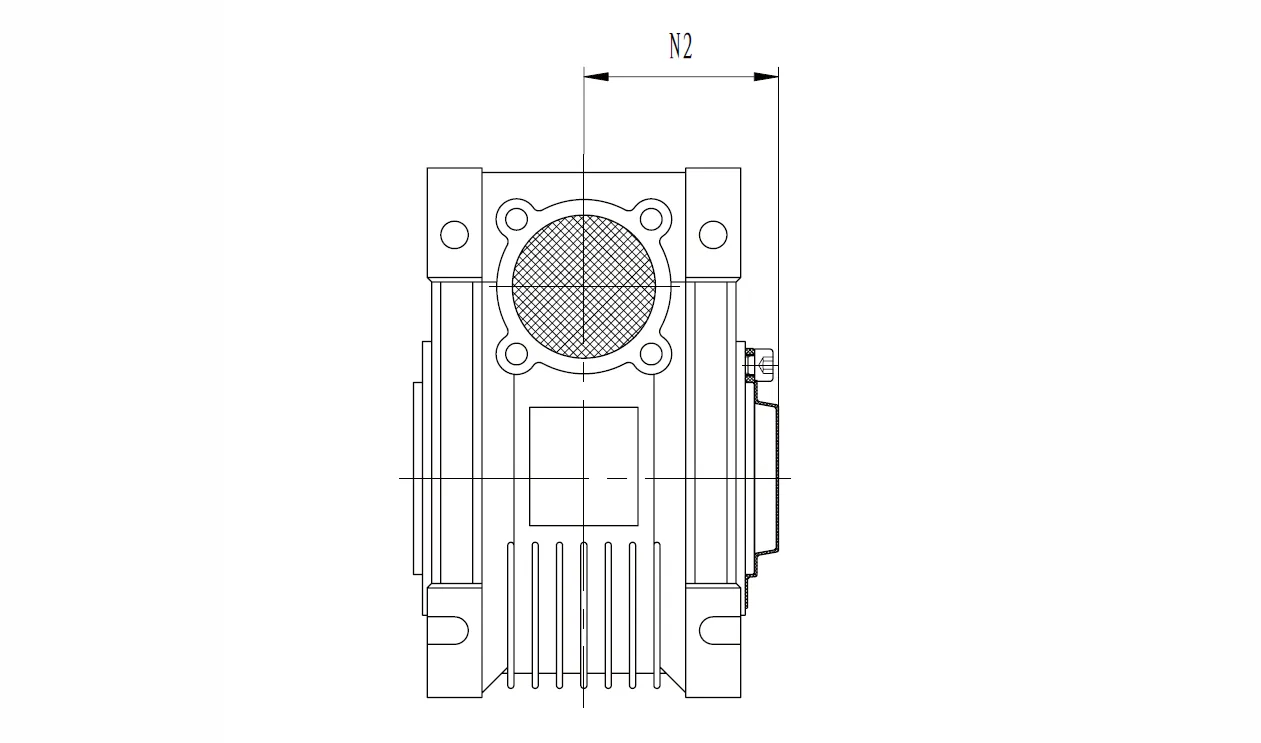

Protective Cover Dimensions

| CMN-NRV-F | N2 |

| 030 | 42 |

| 040 | 50 |

| 050 | 58 |

| 063 | 69 |

| 075 | 74 |

| 090 | 86 |

| 110 | 94 |

| 130 | 102 |

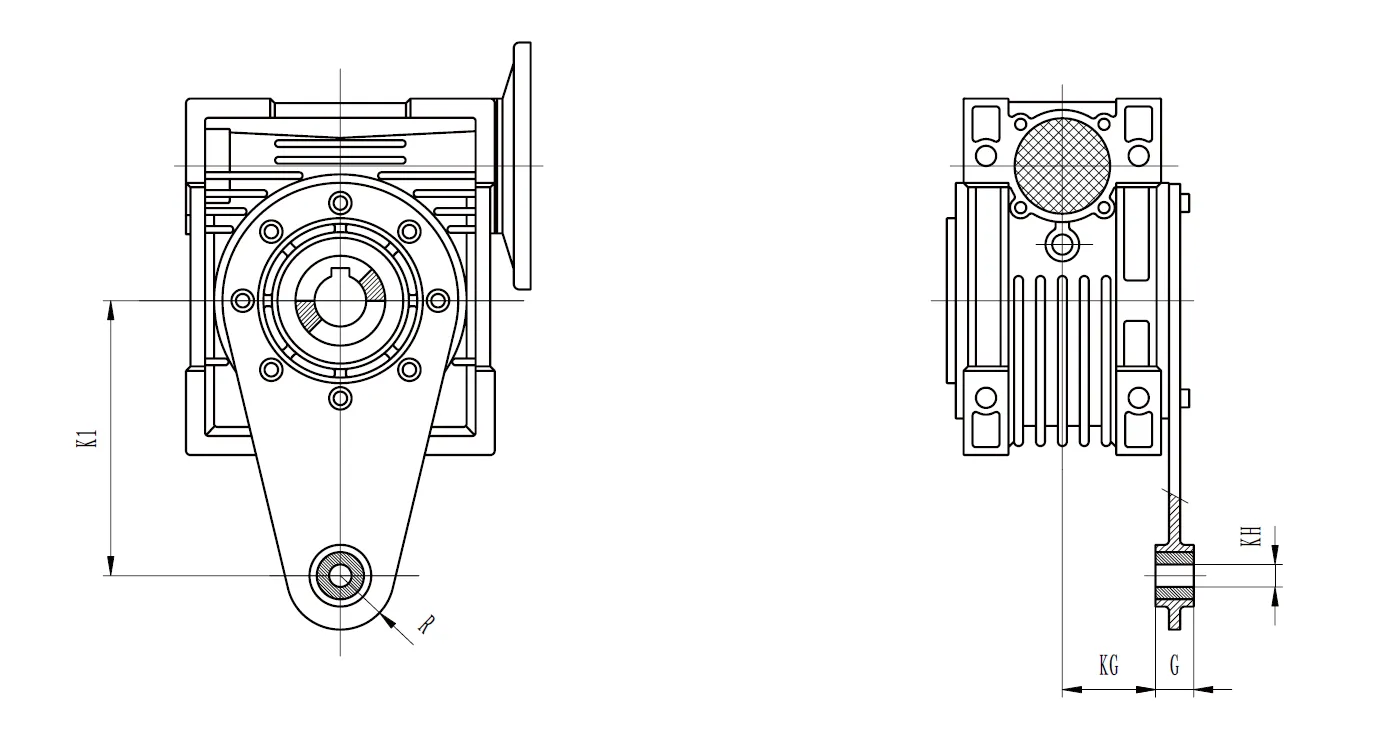

Torque Arm Dimensions

| CMN-NRV-F | K1 | G | KG | KH | R |

| 025 | 70 | 14 | 17.5 | 8 | 15 |

| 030 | 85 | 14 | 24 | 8 | 15 |

| 040 | 100 | 14 | 31.5 | 10 | 18 |

| 050 | 100 | 14 | 38.5 | 10 | 18 |

| 063 | 150 | 14 | 49 | 10 | 18 |

| 075 | 200 | 25 | 47.5 | 20 | 30 |

| 090 | 200 | 25 | 57.5 | 20 | 30 |

| 110 | 250 | 30 | 62 | 25 | 35 |

| 130 | 250 | 30 | 69 | 25 | 35 |

CMN-NRV-F Worm Gear Reducer Design Features

1. Compact and Space-Saving Design

The CMN-NRV-F worm gear reducer is designed with a highly compact structure, allowing it to fit into tight spaces in industrial machinery. Its flange-mounted output and input shaft configuration ensure seamless integration into limited setups without compromising performance or functionality.

2. High Torque Transmission Efficiency

This worm drive gearbox offers exceptional torque transmission capabilities, thanks to its advanced worm gear mechanism. It ensures minimal energy loss and smooth operation, making it suitable for applications requiring precise power delivery and the ability to handle heavy loads under continuous working conditions.

3. Durable and Reliable Construction

Built with high-quality materials such as cast iron and aluminum alloy housings, the CMN-NRV-F worm gear speed reducer is engineered for long-lasting durability. Its resistance to wear, corrosion, and thermal stress ensures reliable performance even in harsh industrial environments or under extended operational cycles.

4. Flange-Mounted Output for Versatility

The output flange enables direct mounting to a wide range of machinery and equipment. This feature ensures precise alignment, reduces installation time, and enhances the versatility of the reducer, making it adaptable to diverse industrial and automation applications.

5. Smooth and Quiet Operation

The worm gear mechanism minimizes vibration and noise during operation. This makes the CMN-NRV-F worm reducer gearbox ideal for industries where silent operation is critical, such as in food processing, packaging lines, and environments requiring minimal noise pollution.

6. Wide Range of Gear Ratios

The CMN-NRV-F worm gear gearbox series offers a variety of gear ratios and configurations to meet specific application needs. This flexibility allows users to select the perfect reducer model that matches their speed, torque, and operational requirements, enhancing system efficiency.

CMN-NRV-F Worm Reducer Gearbox Uses

1. Material Handling and Conveyor Systems

The CMN-NRV-F worm reducer gearbox is widely used in conveyor systems and material handling applications. It provides smooth and reliable torque transmission for continuous operation. This makes it ideal for industries like logistics, warehousing, and manufacturing that require efficient movement of goods.

2. Packaging Machinery

In the packaging industry, the CMN-NRV-F worm drive gearbox ensures precise motion control and smooth operation. Its compact design and high torque capabilities make it suitable for driving packaging lines, sealing machines, and labeling equipment, ensuring consistent and accurate output during high-speed operations.

3. Food Processing Equipment

The worm gear drive gearbox is highly suitable for food processing machinery such as mixers, slicers, and conveyors. Its quiet operation and robust construction ensure reliable performance in environments where hygiene, efficiency, and continuous operation are critical for production and safety.

4. Textile and Printing Machines

CMN-NRV-F worm gear reducers are extensively used in textile processing and printing machines, where precise speed reduction and torque control are required. They ensure smooth operation, helping to maintain accuracy in processes like weaving, dyeing, and high-speed printing, even under heavy workloads.

5. Agricultural Machinery

Agricultural equipment such as seeders, sprayers, and irrigation systems benefit from the worm drive gearbox’s ability to handle heavy loads and operate reliably in dusty or outdoor conditions. Its durability and efficiency make it an excellent choice for demanding agricultural applications requiring long-term performance.

6. Industrial Automation Systems

The CMN-NRV-F worm gear speed reducer is a critical component in industrial automation systems, enabling accurate motion control for robotic arms, automated assembly lines, and CNC machines. Its versatility and high efficiency contribute to the seamless integration of machinery in automated processes, improving productivity.

Additional information

| Edited by | Yjx |

|---|