CMN-NMRV-NMRV Worm Gear Reducers/Worm Gearbox

CMN-NMRV-NMRV double worm gear reducers are advanced mechanical devices used to transmit power and reduce speed in various industrial applications. These gear reducers consist of two CMN-NMRV worm gear units connected in tandem, offering compact design, high efficiency, and excellent torque transmission. The primary function of these reducers is to achieve a significant reduction in rotational speed while increasing torque output, making them ideal for applications requiring precise motion control and heavy load handling.

CMN-NMRV-NMRV double worm gear reducers are advanced mechanical devices used to transmit power and reduce speed in various industrial applications. These gear reducers consist of two CMN-NMRV worm gear units connected in tandem, offering compact design, high efficiency, and excellent torque transmission. The primary function of these reducers is to achieve a significant reduction in rotational speed while increasing torque output, making them ideal for applications requiring precise motion control and heavy load handling.

The modular design of CMN-NMRV-NMRV reducers allows easy assembly and customization, enabling integration with different machinery. They are constructed using high-quality aluminum alloy or cast iron, ensuring durability, corrosion resistance, and lightweight properties. Additionally, they are designed with low noise levels, smooth operation, and minimal maintenance requirements, making them a popular choice in industries such as robotics, conveyors, packaging, and automation systems.

CMN-NMRV-NMRV Worm Gearbox Model & Marker

| CMN-NMRV-040/090-500-VS-F1(FA)-AS-71B5-0.37kW-AS1 | |||

| CMN-NMRV+NMRV | Combined worm geared motor | ||

| CMN-NRV+NMRV | Combined worm reduction unit | ||

| 040/090 | Center distance | ||

| 500 | Reduction ratio | ||

| VS | Double input shaft | F1(FA) | Output flange |

| AS | Single output shaft | AB | Double output shaft |

| PAM | Fitted for motor coupling | 71B5 | Motor size & position |

| 0.37kW | Power of electric motor | AS1 | Mounting position |

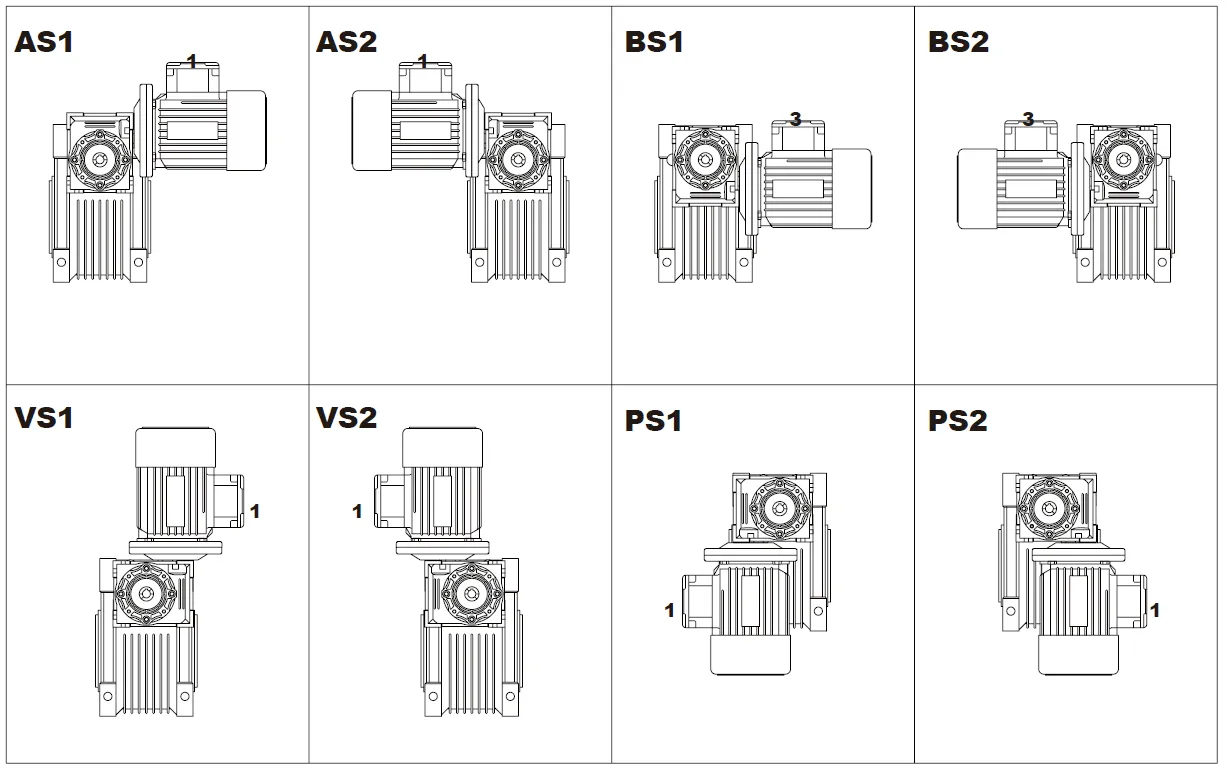

CMN-NMRV-NMRV Mounting Positions

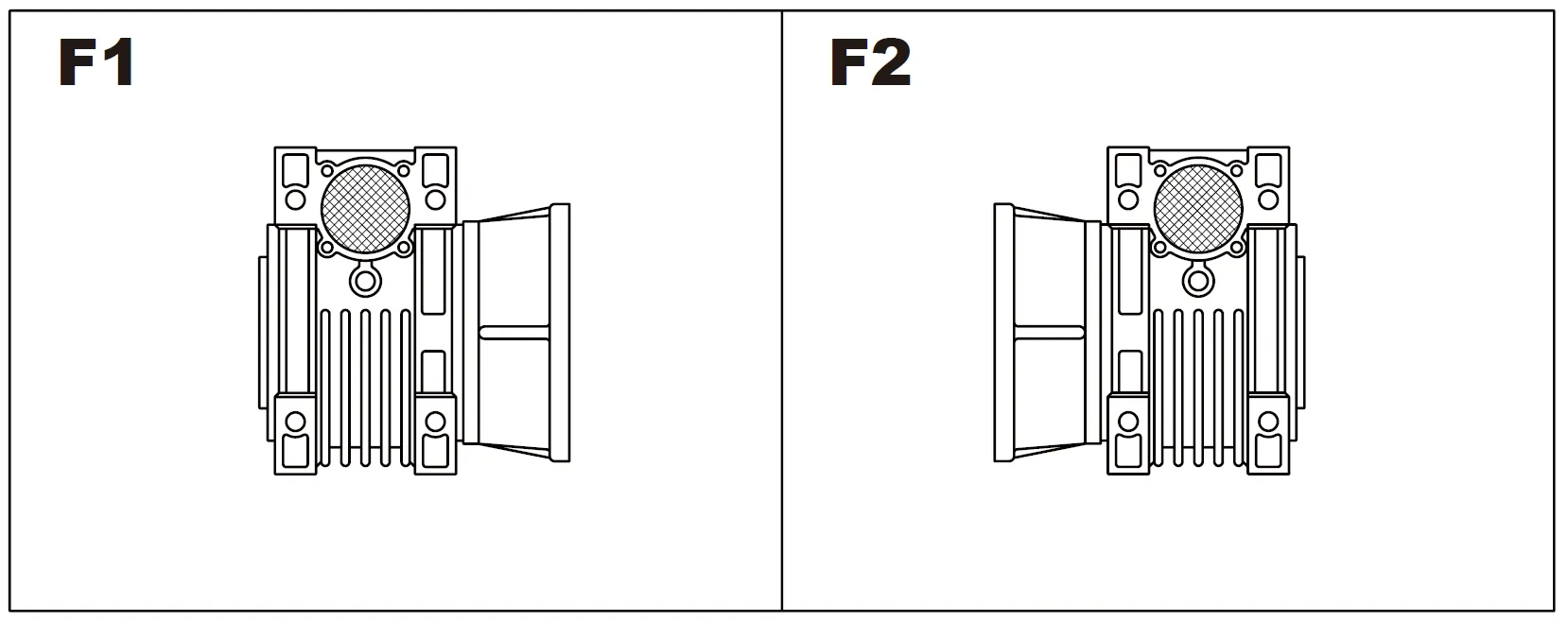

Flange F-FL

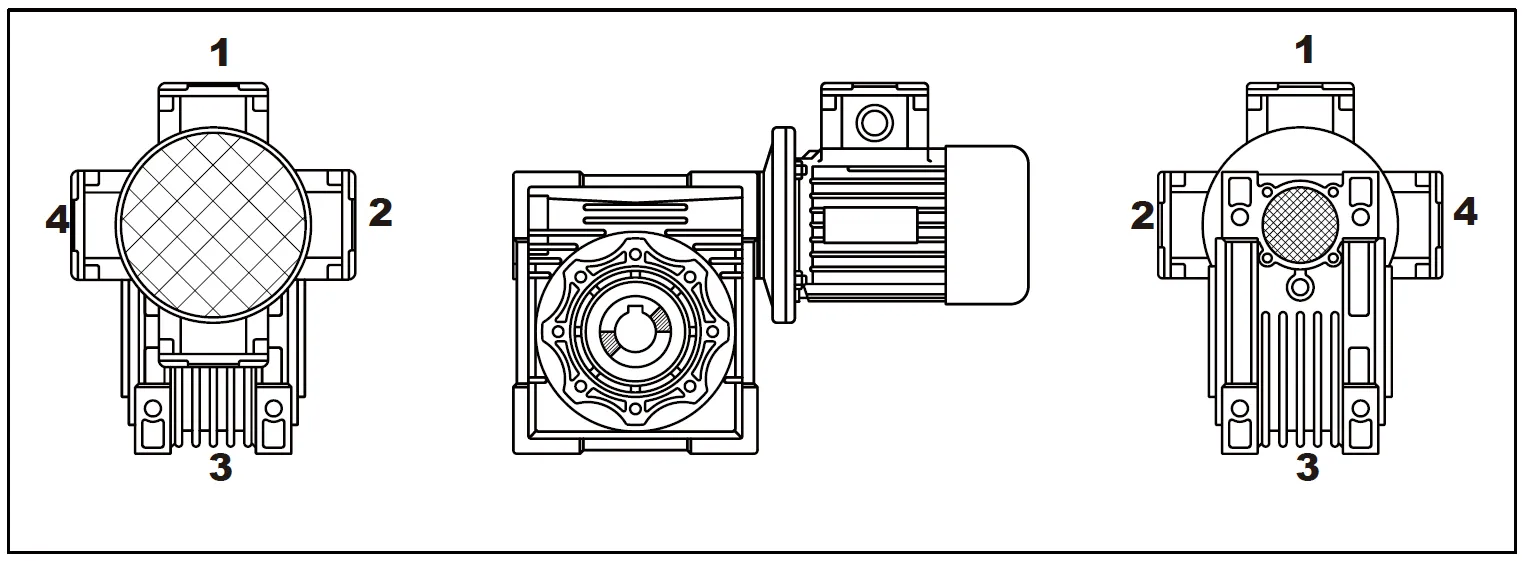

Position of Terminal Box

CMN-NMRV-NMRV Parameter Table

*n1=1400rpm

| i | n2 | kW1 | M2 (Nm) | i1 | i2 | |

| NRV 030/040 | 300 | 4.7 | 0.08 | 73 | 10 | 30 |

| 400 | 3.5 | 0.06 | 65 | 10 | 40 | |

| 500 | 2.8 | 0.04 | 61 | 20 | 25 | |

| 600 | 2.3 | 0.04 | 73 | 20 | 30 | |

| 750 | 1.9 | 0.04 | 73 | 25 | 30 | |

| 900 | 1.6 | 0.03 | 73 | 30 | 30 | |

| 1200 | 1.2 | 0.02 | 65 | 30 | 40 | |

| 1500 | 0.9 | 0.02 | 73 | 50 | 30 | |

| 1800 | 0.8 | 0.02 | 73 | 60 | 30 | |

| 2400 | 0.58 | 0.01 | 65 | 60 | 40 | |

| 3200 | 0.4 | 0.01 | 65 | 80 | 40 | |

| 4000 | 0.4 | 0.01 | 33 | 50 | 80 | |

| 5000 | 0.28 | 0.01 | 29 | 50 | 100 | |

| NRV 030/050 | 300 | 4.7 | 0.15 | 145 | 10 | 30 |

| 400 | 3.5 | 0.1 | 124 | 10 | 40 | |

| 500 | 2.8 | 0.09 | 120 | 10 | 50 | |

| 600 | 2.3 | 0.08 | 145 | 20 | 30 | |

| 750 | 1.9 | 0.07 | 145 | 25 | 30 | |

| 900 | 1.6 | 0.06 | 145 | 30 | 30 | |

| 1200 | 1.2 | 0.04 | 124 | 30 | 40 | |

| 1500 | 0.93 | 0.04 | 145 | 50 | 30 | |

| 1800 | 0.78 | 0.04 | 145 | 60 | 30 | |

| 2400 | 0.6 | 0.03 | 124 | 60 | 40 | |

| 3000 | 0.5 | 0.02 | 120 | 60 | 50 | |

| 4000 | 0.35 | 0.02 | 82 | 50 | 80 | |

| 4800 | 0.29 | 0.02 | 82 | 60 | 80 | |

| NRV 030/063 | 300 | 4.7 | 0.24 | 230 | 7.5 | 40 |

| 400 | 3.5 | 0.19 | 230 | 10 | 40 | |

| 500 | 2.8 | 0.15 | 216 | 10 | 50 | |

| 600 | 2.3 | 0.13 | 230 | 15 | 40 | |

| 750 | 1.9 | 0.11 | 216 | 15 | 50 | |

| 900 | 1.6 | 0.09 | 198 | 15 | 60 | |

| 1200 | 1.2 | 0.08 | 230 | 30 | 40 | |

| 1500 | 0.93 | 0.06 | 216 | 30 | 50 | |

| 1800 | 0.78 | 0.05 | 198 | 30 | 60 | |

| 2400 | 0.58 | 0.05 | 230 | 60 | 40 | |

| 3000 | 0.47 | 0.04 | 216 | 60 | 50 | |

| 4000 | 0.35 | 0.03 | 172 | 50 | 80 | |

| 5000 | 0.28 | 0.02 | 150 | 50 | 100 | |

| NRV 040/075 | 300 | 4.7 | 0.36 | 390 | 10 | 30 |

| 400 | 3.5 | 0.27 | 360 | 10 | 40 | |

| 500 | 2.8 | 0.21 | 320 | 10 | 50 | |

| 600 | 2.3 | 0.19 | 390 | 20 | 30 | |

| 750 | 1.9 | 0.16 | 390 | 25 | 30 | |

| 900 | 1.6 | 0.14 | 390 | 30 | 30 | |

| 1200 | 1.2 | 0.11 | 360 | 30 | 40 | |

| 1500 | 0.93 | 0.1 | 390 | 50 | 30 | |

| 1800 | 0.78 | 0.09 | 390 | 60 | 30 | |

| 2400 | 0.58 | 0.07 | 360 | 60 | 40 | |

| 3000 | 0.47 | 0.05 | 320 | 60 | 50 | |

| 4000 | 0.35 | 0.04 | 250 | 50 | 80 | |

| 5000 | 0.28 | 0.03 | 230 | 50 | 100 |

| i | n2 | kW1 | M2 (Nm) | i1 | i2 | |

| NRV 040/090 | 300 | 4.7 | 0.56 | 610 | 7.5 | 40 |

| 400 | 3.5 | 0.43 | 610 | 10 | 40 | |

| 500 | 2.8 | 0.34 | 560 | 10 | 50 | |

| 600 | 2.3 | 0.3 | 610 | 15 | 40 | |

| 750 | 1.9 | 0.23 | 560 | 15 | 50 | |

| 900 | 1.6 | 0.19 | 505 | 15 | 60 | |

| 1200 | 1.2 | 0.17 | 610 | 30 | 40 | |

| 1500 | 0.93 | 0.14 | 560 | 30 | 50 | |

| 1800 | 0.78 | 0.11 | 505 | 30 | 60 | |

| 2400 | 0.58 | 0.11 | 610 | 60 | 40 | |

| 3000 | 0.47 | 0.08 | 560 | 60 | 50 | |

| 4000 | 0.35 | 0.08 | 460 | 50 | 80 | |

| 5000 | 0.28 | 0.06 | 410 | 50 | 100 | |

| NRV 050/110 | 300 | 4.7 | 0.95 | 1100 | 10 | 30 |

| 400 | 3.5 | 0.69 | 1030 | 10 | 40 | |

| 500 | 2.8 | 0.56 | 1000 | 10 | 50 | |

| 600 | 2.3 | 0.48 | 1030 | 15 | 40 | |

| 750 | 1.9 | 0.43 | 1100 | 25 | 30 | |

| 900 | 1.6 | 0.38 | 1100 | 30 | 30 | |

| 1200 | 1.2 | 0.27 | 1030 | 30 | 40 | |

| 1500 | 0.93 | 0.28 | 1100 | 50 | 30 | |

| 1800 | 0.78 | 0.23 | 1100 | 60 | 30 | |

| 2400 | 0.58 | 0.17 | 1030 | 60 | 40 | |

| 3000 | 0.47 | 0.14 | 1000 | 60 | 50 | |

| 4000 | 0.35 | 0.12 | 780 | 50 | 80 | |

| 5000 | 0.28 | 0.09 | 710 | 50 | 100 | |

| NRV 063/130 | 300 | 4.7 | 1.48 | 1760 | 10 | 30 |

| 400 | 3.5 | 1.09 | 1650 | 10 | 40 | |

| 500 | 2.8 | 0.86 | 1550 | 10 | 50 | |

| 600 | 2.3 | 0.76 | 1650 | 15 | 40 | |

| 750 | 1.9 | 0.66 | 1760 | 25 | 30 | |

| 900 | 1.6 | 0.58 | 1760 | 30 | 30 | |

| 1200 | 1.2 | 0.43 | 1650 | 30 | 40 | |

| 1500 | 0.93 | 0.39 | 1760 | 50 | 30 | |

| 1800 | 0.78 | 0.35 | 1760 | 60 | 30 | |

| 2400 | 0.58 | 0.25 | 1650 | 60 | 40 | |

| 3000 | 0.47 | 0.2 | 1550 | 60 | 50 | |

| 4000 | 0.35 | 0.15 | 1220 | 50 | 80 | |

| 5000 | 0.28 | 0.11 | 1100 | 50 | 100 |

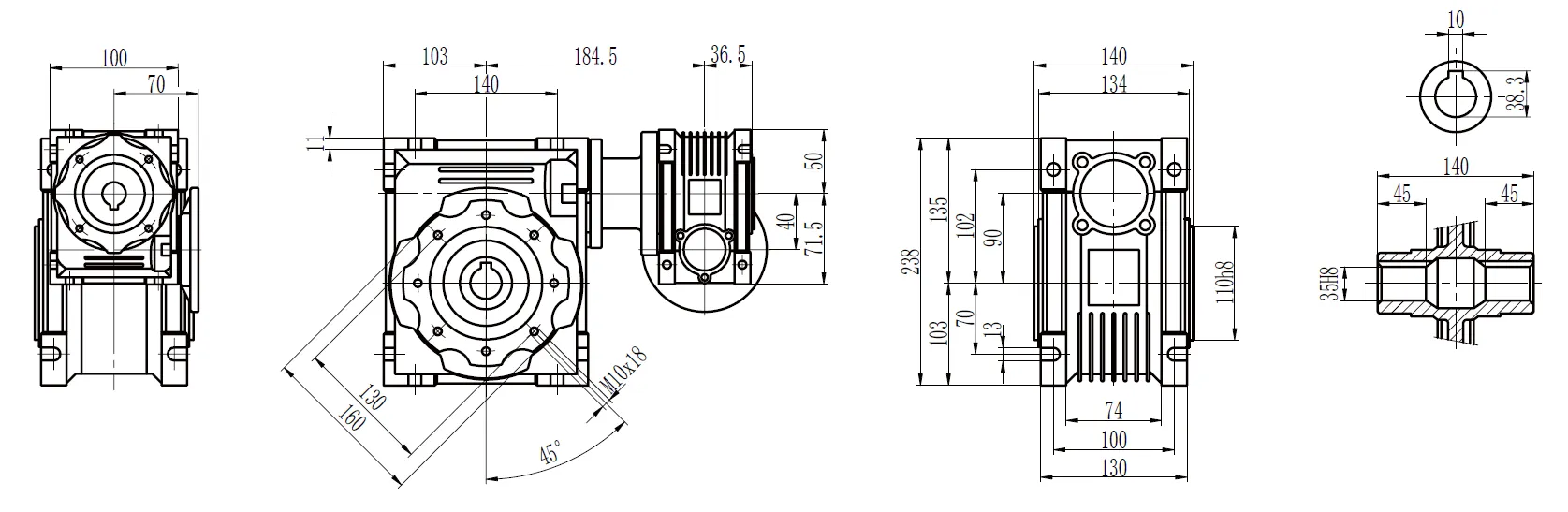

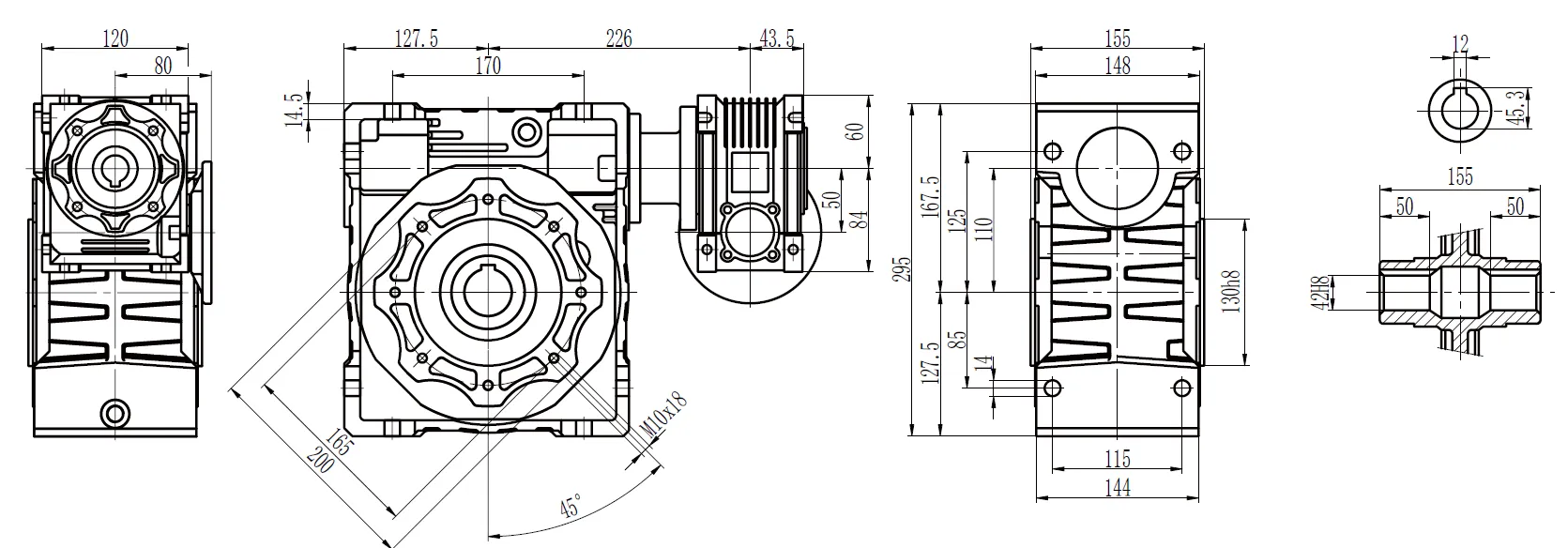

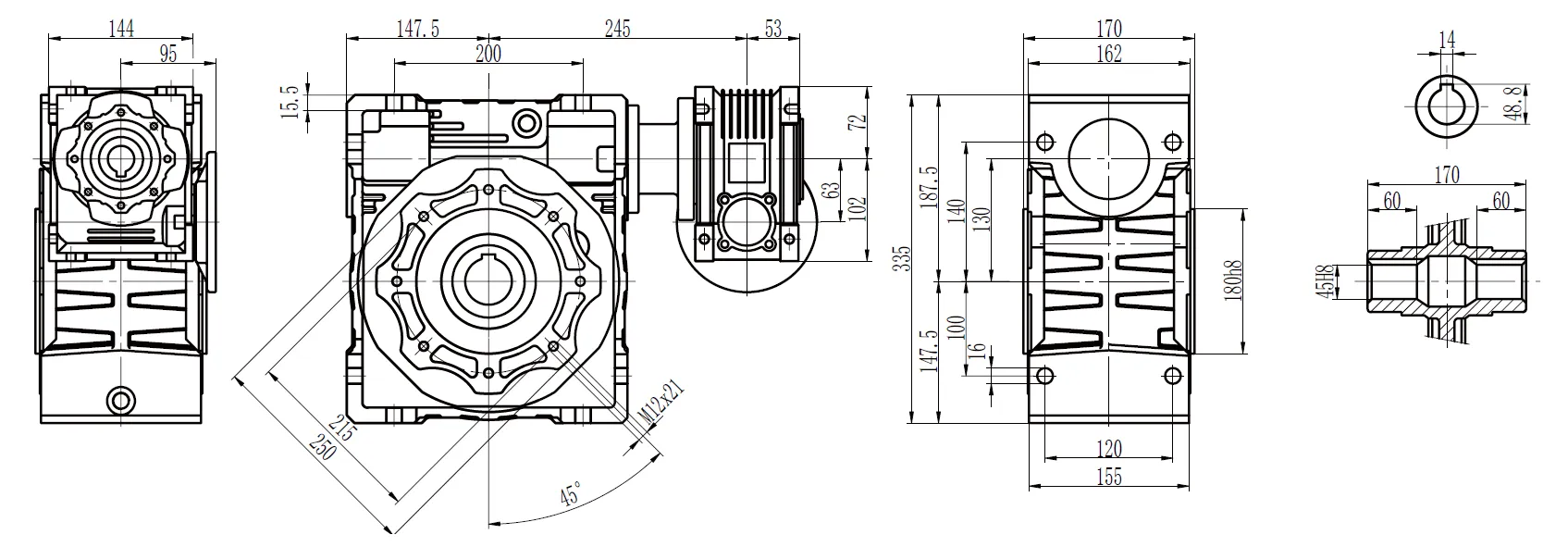

CMN-NMRV-NMRV Worm Gear Reducer Dimensions

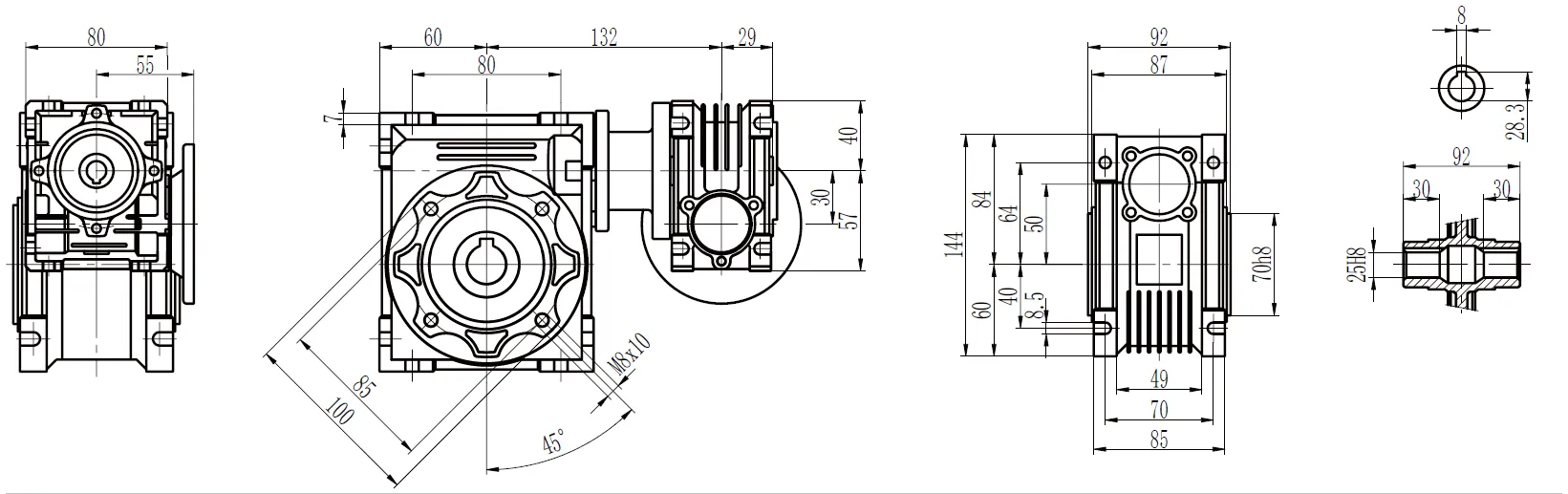

CMN-NMRV 025 -CMN-NMRV 030

CMN-NMRV 025 - CMN-NMRV 040

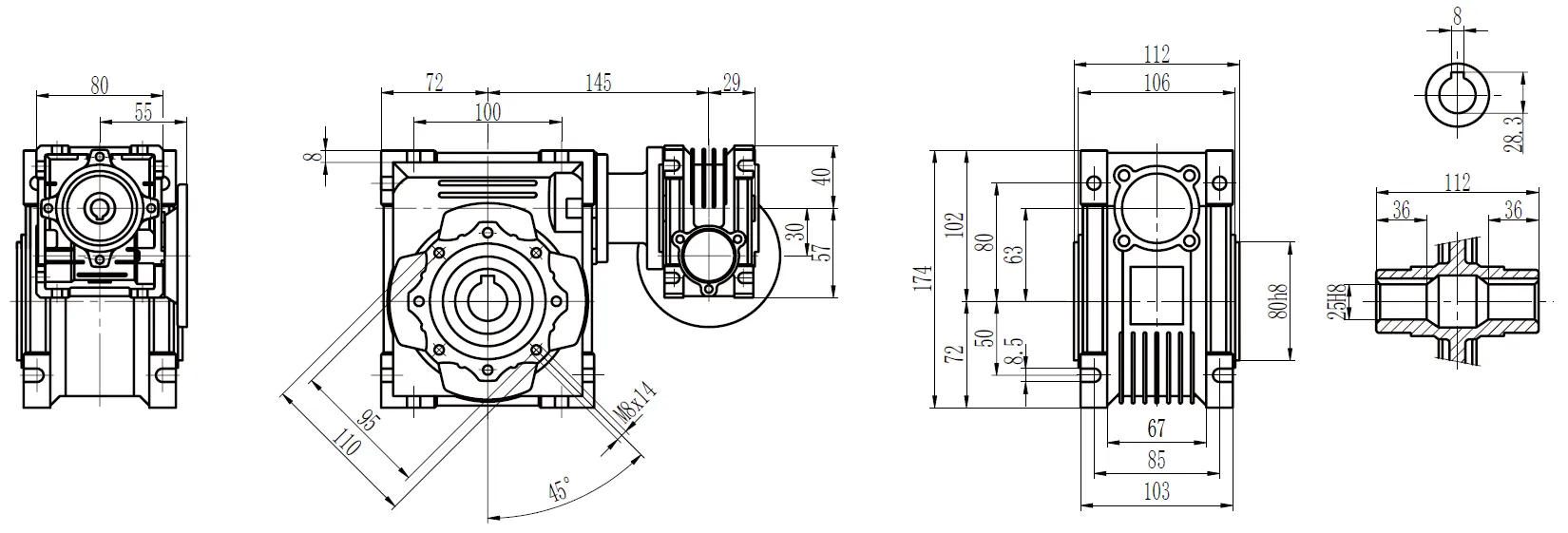

CMN-NMRV 030 - CMN-NMRV 040

CMN-NMRV 030 - CMN-NMRV 050

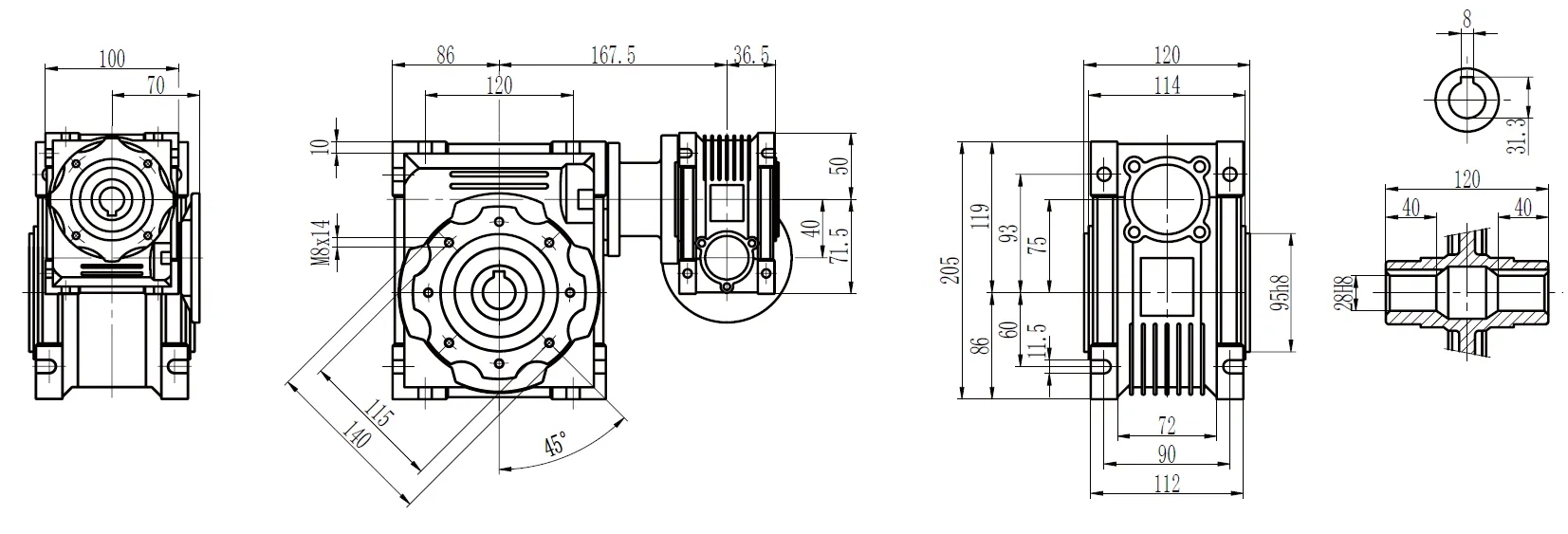

CMN-NMRV 030 - CMN-NMRV 063

CMN-NMRV 040 - CMN-NMRV 075

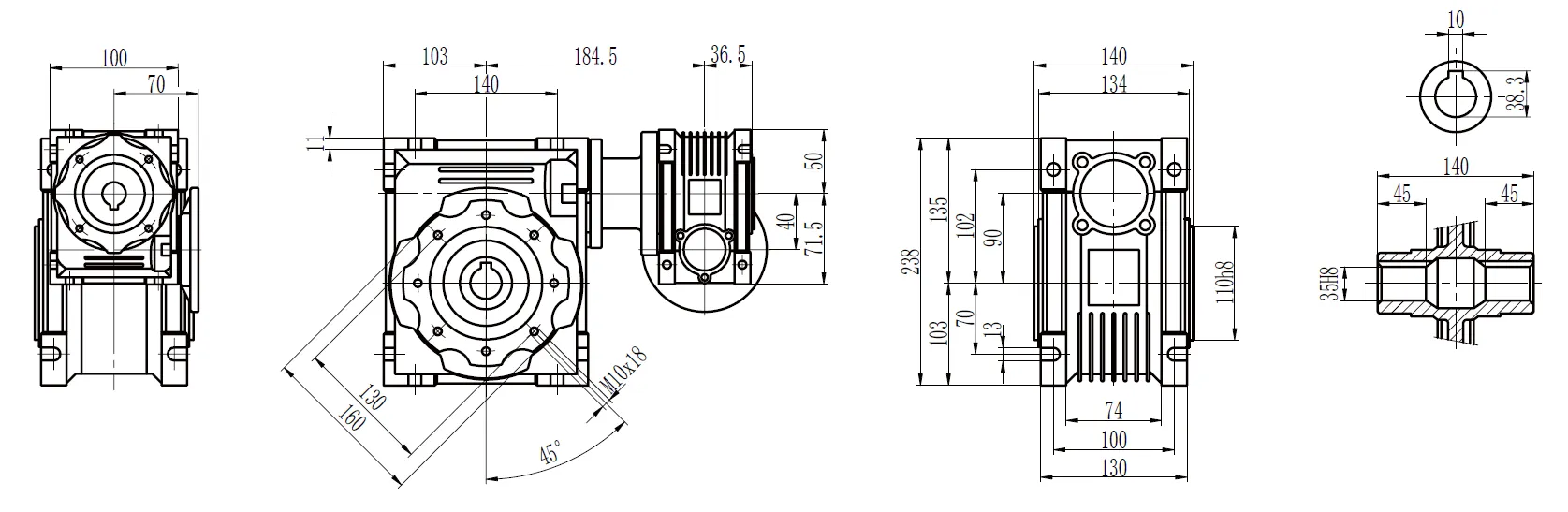

CMN-NMRV 040 - CMN-NMRV 090

CMN-NMRV 050 - CMN-NMRV 110

CMN-NMRV 063 - CMN-NMRV 130

CMN-NMRV-NMRV Double Worm Gearbox Features

CMN-NMRV-NMRV Double Worm Gear Reducer Uses

- Conveyor Systems in Manufacturing

The CMN-NMRV-NMRV double worm gear reducer is widely used in conveyor systems due to its ability to provide precise speed control and high torque output. It ensures smooth operation for transporting heavy materials across production lines in factories and warehouses. - Packaging Machinery

This worm gear speed reducer is ideal for packaging equipment where accurate motion control is essential. Its compact design, quiet operation, and ability to handle varying loads make it suitable for machines that require consistent and reliable performance in high-speed packaging processes. - Robotics and Automation Systems

In robotics and automated systems, the double worm gearbox ensures precise positioning and smooth movement. Its high torque and reduction capabilities enable robots to perform complex tasks with accuracy, even in compact spaces and under heavy load conditions. - Cranes and Hoisting Equipment

The worm drive gearbox is commonly used in cranes and hoisting systems to achieve controlled lifting and lowering of heavy objects. Its robust design and torque amplification ensure safe and efficient handling of loads in construction, logistics, and industrial applications. - Agricultural Machinery

The CMN-NMRV-NMRV double reduction worm gear reducer plays a crucial role in agricultural equipment like harvesters and irrigation systems. Its ability to handle varying speeds and high torque requirements ensures efficient operation, even in challenging environments such as farms and outdoor fields. - Textile and Printing Machines

In textile manufacturing and printing processes, these worm drive reduction gearboxes ensure precise motion control for rollers and other moving parts. Its smooth and low-noise operation helps maintain high-quality output while accommodating the demanding requirements of continuous production cycles.

|  |

|  |

CMN-NMRV-NMRV Double Worm Drive Gearbox with Motor

The CMN-NMRV-NMRV Double Worm Drive Gearbox with Motor is a highly efficient and compact mechanical system designed to meet the demands of precision torque transmission and speed reduction in industrial applications. This setup combines a double-stage NMRV worm gearbox with an integrated motor, creating a seamless solution for driving machinery requiring precise control and high performance. The combination of the gearbox and motor ensures smooth, quiet, and reliable operation, making it a preferred choice for industries such as manufacturing, automation, robotics, and material handling.

The double worm drive configuration allows for exceptionally high reduction ratios, making it highly effective in applications requiring significant speed reduction and torque amplification. The gearboxes are typically manufactured from durable aluminum alloy or cast iron, ensuring lightweight construction with excellent resistance to wear, corrosion, and harsh environmental conditions. This durability ensures a long service life, even in demanding operational settings.

The motor integration enhances the system’s efficiency, as it eliminates the need for additional coupling mechanisms. The motor can be customized to meet specific power and voltage requirements, ensuring compatibility with diverse applications. Furthermore, the modular design of the gearbox allows for versatile mounting options, enabling installation in horizontal, vertical, or inclined positions to suit the machinery's layout.

The CMN-NMRV-NMRV gearbox with motor is also designed for low maintenance, reducing operational downtime and costs. Its quiet operation and high torque transmission capabilities make it ideal for applications such as automation systems, conveyor belts, hoisting mechanisms, and packaging machinery, where precision and reliability are critical.

Additional information

| Edited by | Yjx |

|---|