Gear Rack for Construction Hoist

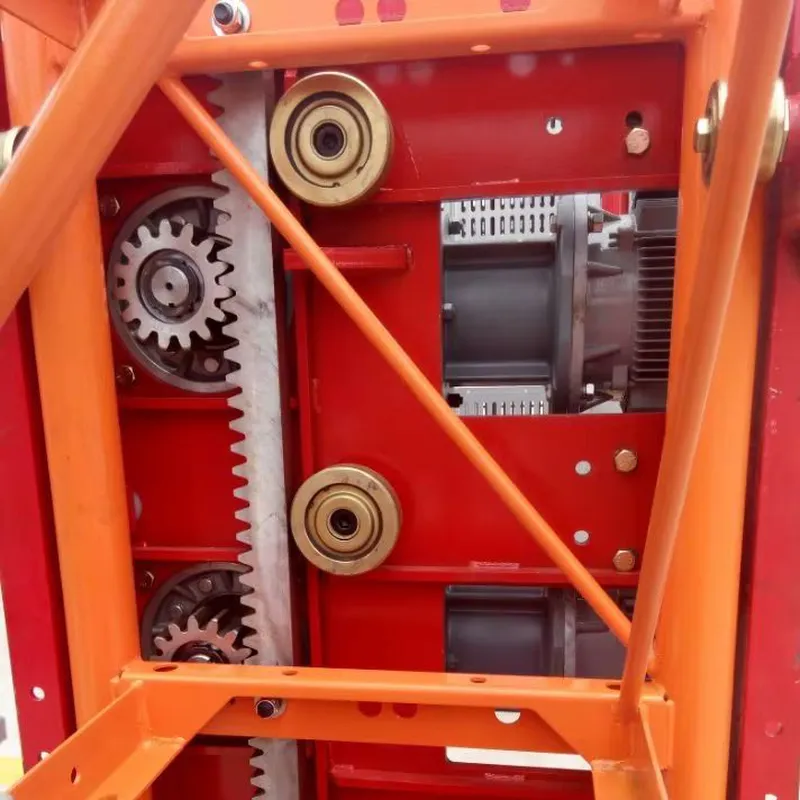

A gear rack for a construction hoist is a critical component in the vertical transportation system used on construction sites to lift materials and personnel to different levels of a building under construction. It is a linear, toothed bar that works in conjunction with a motorized pinion gear, forming a rack-and-pinion mechanism. The construction hoist gear rack is typically mounted along the mast or tower structure of the hoist.

A gear rack for a construction hoist is a critical component in the vertical transportation system used on construction sites to lift materials and personnel to different levels of a building under construction. It is a linear, toothed bar that works in conjunction with a motorized pinion gear, forming a rack-and-pinion mechanism. The construction hoist gear rack is typically mounted along the mast or tower structure of the hoist.

When the pinion gear, powered by an electric motor, rotates, its teeth engage with the gear rack's teeth, converting rotational motion into linear motion. This allows the hoist car to ascend or descend smoothly along the mast. Made of high-strength steel, the gear rack is designed to withstand heavy loads and harsh environmental conditions.

These construction hoist gear racks are essential for ensuring precise, stable, and safe movement of the hoist car, making them indispensable in high-rise construction. Their design also facilitates modular installation and easy maintenance, ensuring continuous operation in demanding construction environments.

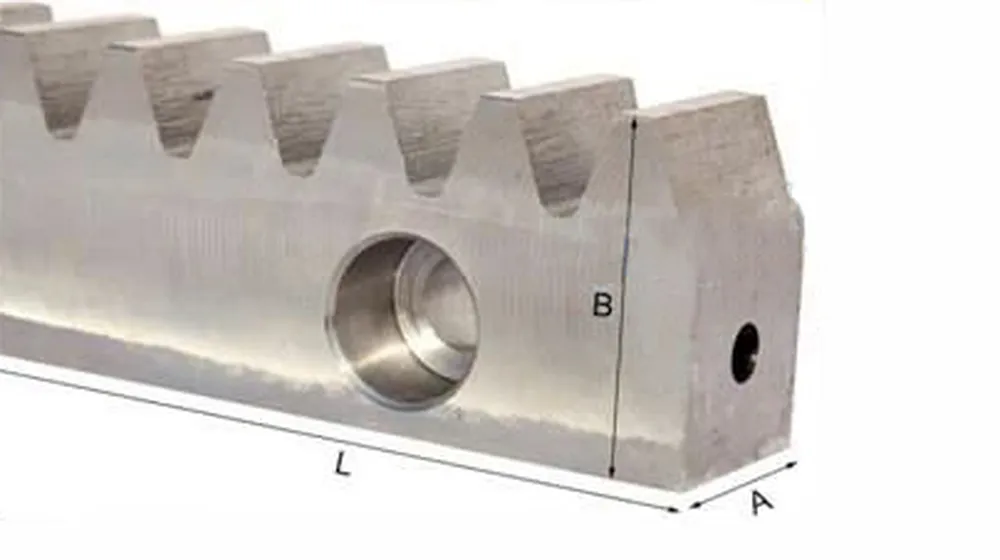

Construction Hoist Gear Rack Dimensions

| Name | Art No. | Description | A (mm) | B | L | Weight (kg) |

| Construction Hoist Gear Rack | HR-40x40x1508 | C60 steel Module M5 | 40 | 40 | 1508 | 16.8 |

| HR-40x50x1508 | C60 steel Module M8 | 40 | 50 | 1508 | 20 | |

| HR-40x60x1508 | 40 | 60 | 1508 | 23.8 | ||

| HR-50x50x1508 | 50 | 50 | 1508 | 24.9 | ||

| HR-40x60x1483 | 40 | 60 | 1483 | 23.4 |

Features of Construction Hoist Gear Racks

- High precision

Due to the unidirectional motion of the rack, the friction loss is small, and the position control precision is high. The gear teeth on the rack can mesh with the gears in the mechanical device to achieve precise positioning and control. - Large transmission power

The rack can withstand movement with a certain impact load, cooperate with the gear, and transmit power through the gear drive. At the same time, it can also realize movement through its own movement. - Smooth movement

The meshing method of the gear rack makes it run smoothly, and the phenomenon of jumping is rarely caused. The change in speed will not affect its performance. - Low noise

The surface finish is high, which can effectively reduce noise and ensure quiet operation, which can meet the low noise requirements of machine operation. - High reliability

The rack is reliable in operation and has a long service life. It does not require regular maintenance and replacement. It also has good sealing performance, which can prevent dust, water vapor, and other foreign objects from entering, thereby prolonging its service life. - Simple structure

The structure of the rack is relatively simple, the process is easy to grasp, and the manufacturing cost is relatively low. At the same time, the shape and size of the rack are relatively stable, which makes it easy for batch production and processing.

|  |

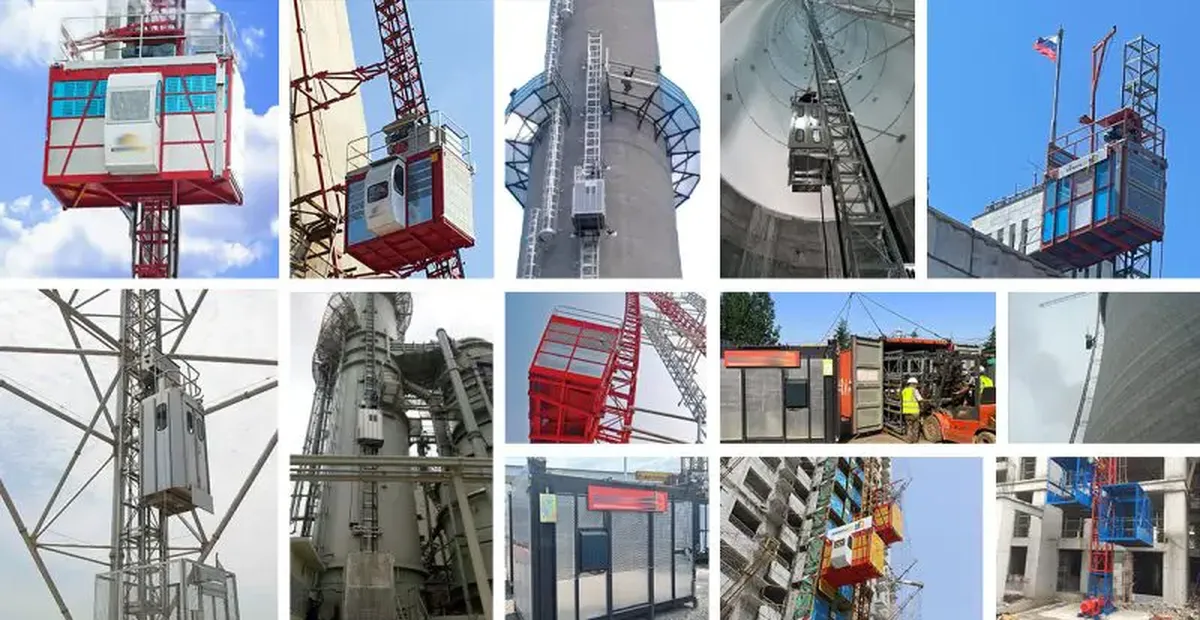

Construction Hoist Gear Rack and Pinion Applications

- High-Rise Building Construction

Gear rack and pinion systems are widely used in construction hoists for high-rise building projects to transport workers, tools, and materials efficiently. Their ability to provide smooth vertical movement ensures safe and reliable operations at extreme heights during construction work. - Bridge and Tower Maintenance

These systems are essential for accessing elevated sections of bridges and towers for maintenance, inspections, and repairs. Their precise motion mechanism allows workers to safely reach specific areas, even in challenging environments, ensuring the stability and longevity of such structures. - Industrial Plant Construction

In industrial facilities like power plants or refineries, construction hoist gear rack and pinion hoists are used to lift heavy machinery and construction materials to different levels. Their high load-bearing capacity ensures efficient handling of oversized equipment in critical and time-sensitive projects. - Offshore and Marine Applications

Gear racks and pinions are utilized in offshore platforms and shipbuilding to lift materials and personnel. Their robust design ensures reliable performance in harsh marine environments where high humidity, salt exposure, and heavy loads are common challenges. - Facade and Cladding Installation

During the installation of building facades and cladding systems, these hoists provide precise movement along the exterior walls. This enables workers to transport materials and position themselves accurately at the required height for safe and efficient installation work. - Demolition Projects

In controlled demolition projects, construction hoist gear rack and pinion help transport heavy debris and dismantled materials from upper floors to the ground. Their ability to handle heavy loads and operate safely in unstable conditions makes them ideal for such applications.

Common Troubleshooting of Gear Rack for Construction Hoist

- Excessive Noise During Operation

If the gear rack produces unusual noise, it may indicate misalignment between the rack and pinion or insufficient lubrication. Inspect the alignment carefully and apply quality lubricants to reduce friction. Regular maintenance can prevent noise caused by wear and tear. - Uneven or Jerky Movement

Jerky or uneven hoist movement can result from damaged teeth on the gear rack or pinion. Thoroughly inspect both components for wear, cracks, or missing teeth. Replace any damaged parts promptly to restore smooth and safe operation of the hoist. - Corrosion or Rust Formation

Exposure to harsh weather conditions can lead to rust or corrosion on the gear rack. Regular cleaning and applying anti-corrosion coatings can prevent this issue. If corrosion persists, replace the affected sections to avoid further damage and ensure safe operation. - Insufficient Load Capacity

If the hoist struggles to lift its rated load, check for worn or damaged gear teeth that may be limiting performance. Inspect the motor and pinion gear as well. Replacing faulty parts is essential to restore proper load-handling capacity. - Gear Rack Misalignment

Misalignment between the gear rack and pinion causes operational inefficiency and accelerates component wear. Regularly check alignment and ensure proper installation. Use alignment tools and adjust mounting bolts to achieve precise positioning of the rack and pinion system. - Excessive Wear on Gear Teeth

Rapid wear of gear teeth is often caused by overloading, poor lubrication, or improper material quality. Ensure the hoist is not exceeding its load capacity, use high-quality lubricants, and replace the gear rack with a more durable material if necessary.

Additional information

| Edited by | Yjx |

|---|