Nylon Gear Rack for Sliding Gate

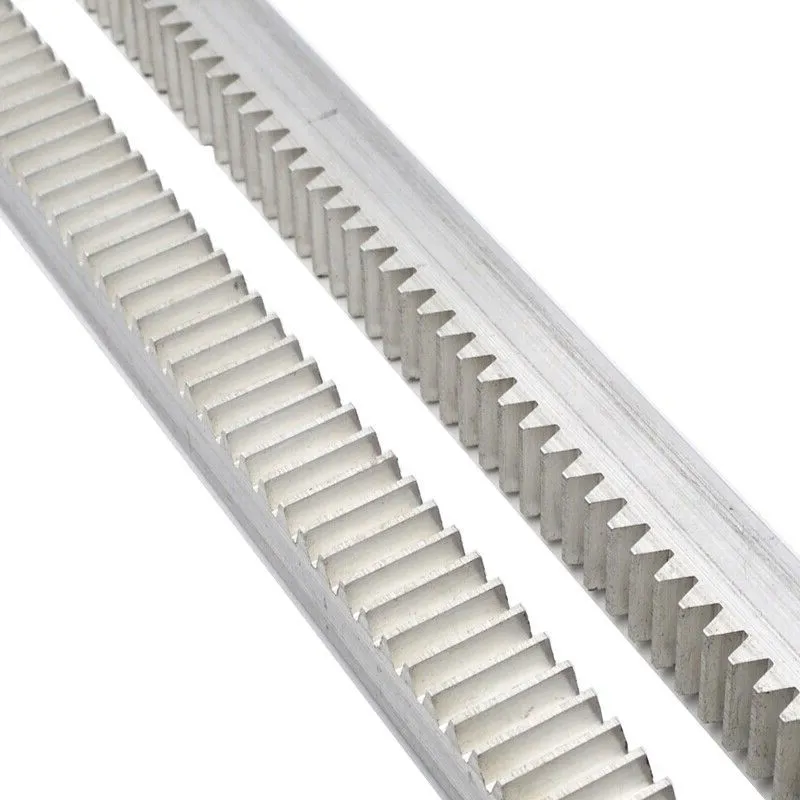

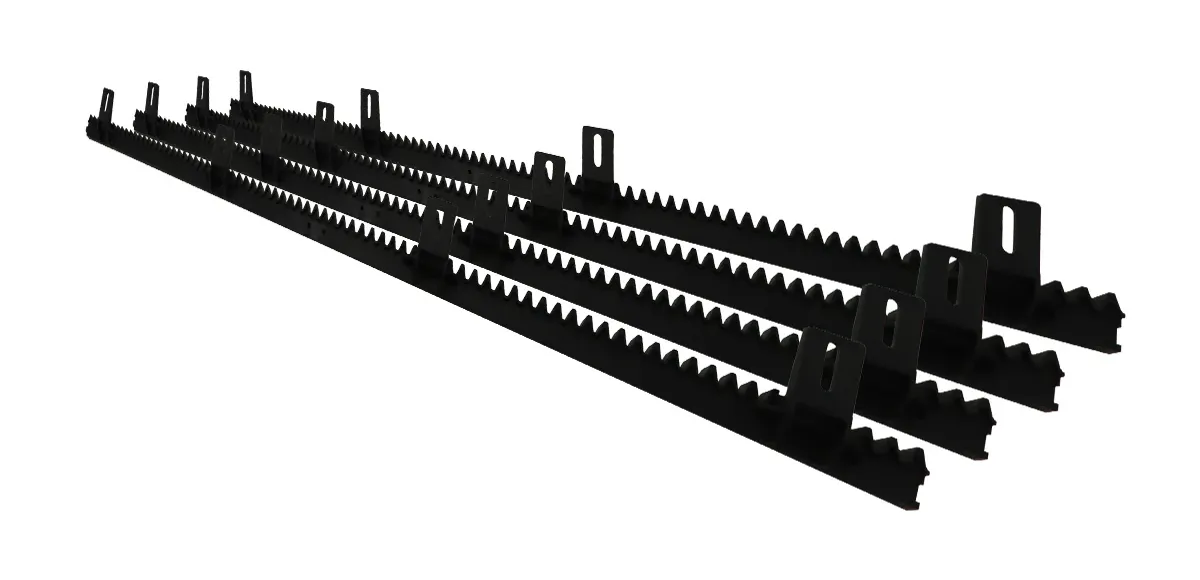

A nylon gear rack for sliding gates is a durable and lightweight mechanical component specifically designed to facilitate the smooth and efficient movement of sliding gates. It consists of a straight, toothed rail made from high-quality nylon material, which is known for its strength, resistance to wear, and corrosion-free properties. The gear rack works in conjunction with a motorized pinion gear connected to the gate’s automation system. As the pinion gear rotates, it engages with the teeth of the nylon rack, propelling the gate open or closed along its track.

A nylon gear rack for sliding gates is a durable and lightweight mechanical component specifically designed to facilitate the smooth and efficient movement of sliding gates. It consists of a straight, toothed rail made from high-quality nylon material, which is known for its strength, resistance to wear, and corrosion-free properties. The gear rack works in conjunction with a motorized pinion gear connected to the gate's automation system. As the pinion gear rotates, it engages with the teeth of the nylon rack, propelling the gate open or closed along its track.

Nylon gear racks are preferred over metal ones in certain applications due to their quieter operation, resistance to rust (especially in outdoor or humid environments), and reduced weight, which makes installation easier. These racks are often used in residential and commercial gates where durability, cost-efficiency, and low maintenance are priorities. Additionally, they can handle moderate loads and are engineered for long-term use, ensuring reliable gate operation.

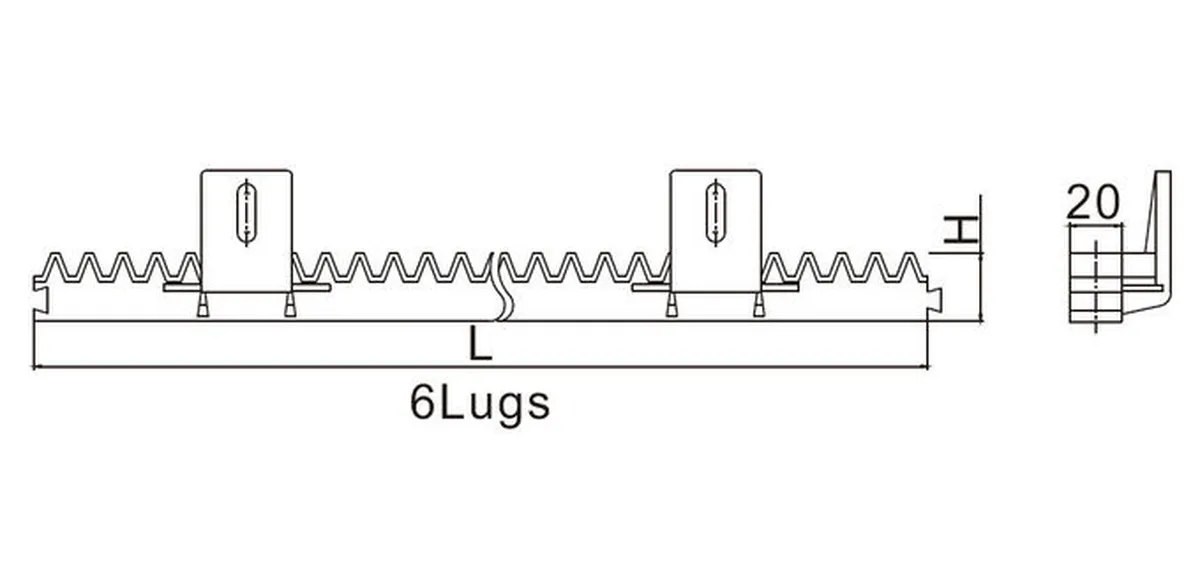

Nylon Sliding Gate Gear Rack Dimensions

|  |

NO. | Module | Lugs | H (mm) | WT(G) |

CT03A(LIGHT) | M4 | 2 lugs | 26 | 299 |

CT03A-Z(HEAVY) | M4 | 2 lugs | 28 | 500 |

CT03B | M4 | 2 lugs | 26 | 856 |

CT03C | M4 | 2 lugs | 27 | 1338 |

Features of Nylon Gear Rack for Sliding Gate

1. Durable Nylon Material Composition

Nylon gear racks are crafted from high-quality nylon, a material renowned for its strength, flexibility, and resistance to wear and tear. This ensures the rack can endure prolonged use in high-friction environments while maintaining its structural integrity over time.

2. Lightweight and Easy to Handle

Compared to metal alternatives, nylon gear rack sliding gate openers are significantly lighter, making transportation, installation, and adjustments more manageable. Their reduced weight does not compromise durability, allowing for ease of use without sacrificing the performance needed for efficient gate operations.

3. Corrosion and Weather Resistance

Nylon is inherently resistant to rust and corrosion, making it ideal for outdoor sliding gates exposed to moisture, humidity, or extreme weather conditions. This resistance ensures the gear rack remains functional and visually intact even after years of exposure.

4. Smooth and Quiet Operation

Nylon gear racks are designed to minimize noise during operation. Unlike metal racks, their smooth surface and flexibility reduce vibrations and friction, enabling a quieter and more seamless movement of the sliding gate along the track.

5. Precision-Machined Gear Teeth

The gear teeth on nylon racks are precisely molded or machined to ensure accurate engagement with the gate’s pinion gear. This precision enhances the overall efficiency and smoothness of the sliding mechanism, reducing wear on both the rack and gear.

6. Versatile and Customizable Design

Nylon gear racks are available in various sizes, lengths, and tooth profiles to suit a wide range of sliding gate systems. They can also be easily cut or adjusted to meet specific installation requirements, providing flexibility for diverse applications.

Nylon Sliding Gate Gear Rack Applications

1. Residential Sliding Gates

Nylon gear racks are widely used in residential sliding gate systems due to their lightweight nature and quiet operation. Homeowners prefer them for their corrosion resistance and low maintenance, ensuring smooth and reliable performance in various weather conditions without frequent repairs.

2. Commercial and Industrial Gates

In commercial and industrial settings, nylon sliding gate gear racks are employed for medium-duty sliding gates. Their durability and ability to handle moderate loads make them suitable for warehouses, factories, and office premises, ensuring efficient access control and secure entry points.

3. Outdoor Gate Systems

Nylon gear racks are ideal for outdoor gates exposed to harsh environmental conditions such as rain, snow, and humidity. Their corrosion-resistant properties prevent rusting or degradation, ensuring long-term performance in gardens, driveways, and perimeter fencing applications.

4. Automatic Sliding Gate Systems

Automatic gate systems often use nylon gear racks because of their compatibility with motorized operations. The precision-molded gear teeth provide smooth engagement with pinion gears, ensuring seamless movement of the gate while minimizing noise and mechanical wear during operation.

5. Gates in Coastal Areas

In coastal regions where salt air and high humidity can quickly corrode metal components, nylon sliding gate gear racks are an excellent choice. Their resistance to saltwater corrosion makes them a reliable and long-lasting solution for gates in marine or beachfront properties.

6. Temporary or Portable Gates

For temporary setups such as event barriers or construction site gates, nylon gear racks are preferred due to their lightweight and easy installation. Their portability and adaptability allow for quick assembly and disassembly while maintaining steady gate operation.

Nylon Gear Racks vs. Steel Gear Racks

Key Differences Between Nylon Gear Racks and Steel Gear Racks

Material Composition and Durability

Nylon gear racks are made from high-quality polymer, offering moderate strength and excellent flexibility. Steel gear racks, on the other hand, are constructed from hardened steel, providing superior strength and durability, making them ideal for heavy-duty applications requiring high load-bearing capacity.

Corrosion Resistance

Nylon gear racks are naturally resistant to moisture, rust, and corrosion, making them well-suited for outdoor environments or humid conditions. Steel gear racks are prone to rust unless treated with protective coatings, which increases maintenance requirements in wet or coastal areas.

Weight and Ease of Installation

Nylon gear racks are lightweight, making them easier to transport, handle, and install compared to steel gear racks. Steel gear racks are significantly heavier, requiring more effort during installation and often demanding additional structural support for proper alignment and operation.

Noise Levels During Operation

Nylon gear racks operate quietly due to their lower friction and flexible material properties, reducing vibrations and noise. Steel gear racks, however, generate more noise during operation, as the rigid metal surfaces create higher friction and vibrations, particularly in motorized systems.

Cost and Affordability

Nylon gear racks are generally more affordable than steel gear racks, making them a cost-effective solution for residential and small-scale applications. Steel gear racks, while more expensive, are a long-term investment for industrial or commercial gates requiring high performance and durability.

Application Suitability

Nylon gear racks are ideal for light to medium-duty gates, such as residential or temporary setups. Steel gear racks, with their higher strength and load capacity, are preferred for industrial, commercial, or large gates that require robust and reliable performance under heavy use.

|  |

| Nylon Gear Racks | Steel Gear Racks |

Additional information

| Edited by | Yjx |

|---|