Steel Gear Rack for Sliding Gate

A steel gear rack for sliding gates is a linear gear system designed to facilitate the smooth and efficient movement of sliding gates. It is an essential component in automated or manual gate systems, enabling the conversion of rotary motion from a gear-driven motor into linear motion to open or close the gate. The sliding gate gear rack is typically made of durable steel for strength and resistance to wear, ensuring long-term functionality under various environmental conditions.

A steel gear rack for sliding gates is a linear gear system designed to facilitate the smooth and efficient movement of sliding gates. It is an essential component in automated or manual gate systems, enabling the conversion of rotary motion from a gear-driven motor into linear motion to open or close the gate. The sliding gate gear rack is typically made of durable steel for strength and resistance to wear, ensuring long-term functionality under various environmental conditions.

The gear rack consists of a straight, toothed bar that meshes with a pinion gear attached to the gate's motor. As the pinion rotates, it moves the rack, propelling the gate along its track. Steel gear racks are available in various lengths, widths, and tooth configurations to suit different gate sizes and weights. They are commonly galvanized or treated for corrosion resistance, making them suitable for outdoor use in residential, commercial, or industrial settings.

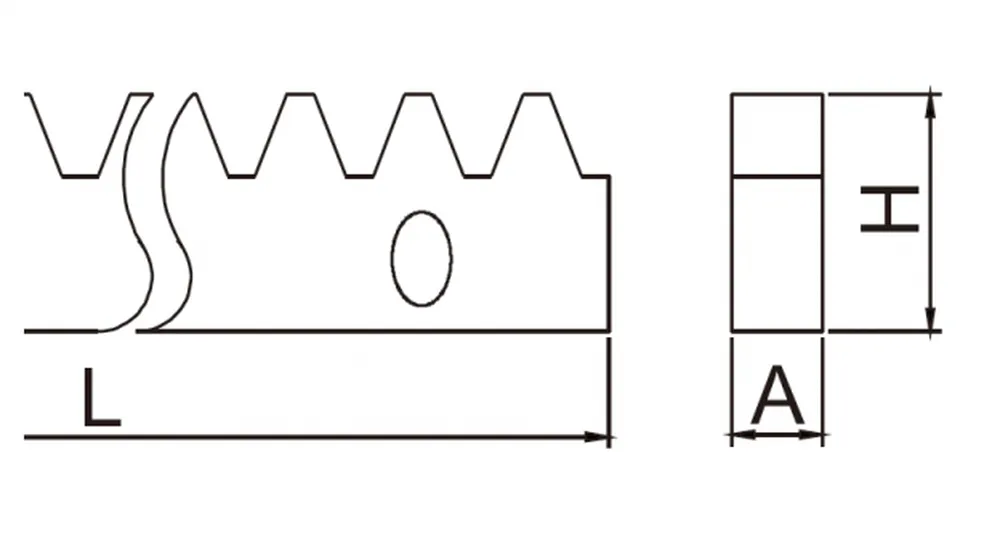

Sliding Gate Gear Rack Dimensions

|  |

| Module | A (mm) | H | L | WT(kg/m) |

| M4 | 8 | 30 | 1m/2m | 1.75 |

| M4 | 9 | 30 | 1m/2m | 1.95 |

| M4 | 10 | 30 | 1m/2m | 2.17 |

| M4 | 11 | 30 | 1m/2m | 2.36 |

| M4 | 12 | 30 | 1m/2m | 2.55 |

| M4 | 22 | 22 | 1m/2m | 3.1 |

| M4 | 30 | 30 | 1m/2m | 5.4 |

Benefits of Steel Gear Rack for Sliding Gate

- Durability and Longevity

Steel gear racks are exceptionally durable due to their robust construction. They can withstand heavy loads and daily use without deformation or damage, even in outdoor environments. Their resistance to wear ensures they remain functional for many years with minimal maintenance. - Smooth and Reliable Operation

The precise design of steel gear racks ensures smooth engagement with the pinion gear. This results in seamless sliding gate movement, avoiding jerks or uneven motion. Their reliability makes them ideal for both residential and industrial applications that require consistent performance. - High Load Capacity

Steel gear racks are capable of handling the weight of large and heavy gates, making them suitable for industrial and commercial settings. Their strength ensures they can support gates made of heavy materials like metal or wood without compromising performance. - Corrosion Resistance

Many steel gear racks are galvanized or treated with anti-corrosion coatings to withstand harsh weather conditions. This makes them suitable for outdoor use, protecting them from rust and deterioration caused by rain, humidity, or extreme temperatures. - Compatibility with Automation Systems

Steel gear racks are designed to integrate seamlessly with automated gate motors. This allows for modern conveniences like remote-controlled or sensor-triggered gate operations, enhancing security and reducing the need for manual labor in operating the gate. - Customizable to Different Needs

Steel gear racks are available in various lengths, widths, and tooth configurations to accommodate gates of different sizes and weights. This flexibility ensures they can be tailored to the specific requirements of any sliding gate system, improving overall efficiency.

Sliding Gate Gear Rack Applications

- Residential Properties

Sliding gate gear racks are widely used in residential properties to enhance security and convenience. They are ideal for automated gates that provide controlled access, ensuring homeowners can open and close gates effortlessly using remote controls or smart systems for added safety. - Commercial Complexes

In commercial settings, gear racks are essential for managing access to parking lots, warehouses, and loading docks. These racks allow for the smooth operation of heavy-duty sliding gates, ensuring efficient access control and protecting valuable assets within commercial premises. - Industrial Facilities

Industrial facilities often use sliding gate gear racks for securing large and heavy-duty gates. These gates are typically required to control the movement of trucks and machinery, and the durable gear racks ensure reliable and consistent operation in rugged environments. - Public Infrastructure

Sliding gate systems with gear racks are commonly employed in public infrastructure projects, such as railway stations and airports. They help manage vehicle and pedestrian access, providing a secure and efficient method of controlling entry in high-traffic areas. - Farms and Agricultural Properties

Sliding gate gear racks are used on farms and agricultural properties to secure entry points to barns, fields, and storage areas. They are particularly useful for handling large gates that must accommodate the movement of tractors and other heavy equipment. - Gated Communities

In gated communities, sliding gate systems with gear racks ensure controlled access for residents and visitors. These systems enhance the community's security while providing a convenient, automated way to manage vehicle and pedestrian entry, contributing to a safer living environment.

How Does the Steel Gear Rack for Sliding Gate Work?

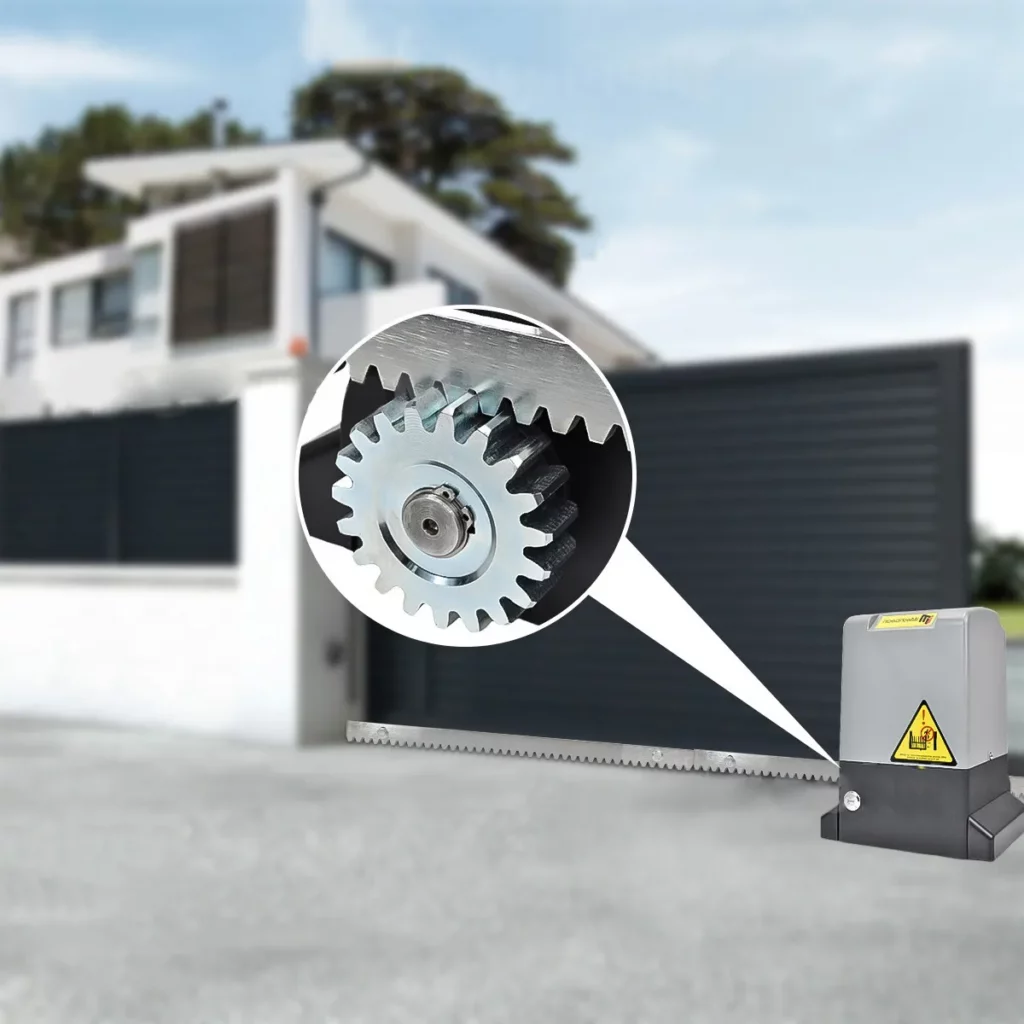

The steel gear rack for sliding gates operates as a critical component in the gate's movement mechanism, enabling the gate to slide smoothly along its track. It works by converting rotary motion from a motor-driven pinion gear into linear motion, which propels the gate open or closed. This process involves precise synchronization between the gear rack and pinion gear to ensure efficient and seamless operation.

The gear rack consists of a straight, toothed steel bar installed along the length of the sliding gate. These teeth are specifically designed to interlock with the teeth of the pinion gear, which is connected to the motor or manual drive mechanism. When the motor is activated, the pinion rotates, engaging with the teeth of the steel rack. This rotational motion translates into linear movement, effectively pushing or pulling the gate along its track.

The material strength of steel ensures the gear rack can handle the weight of heavy gates without bending or wearing out, even under frequent usage. For automated systems, the motor's control unit determines the direction and speed of the gate's movement, ensuring smooth starts and stops. Safety mechanisms, such as sensors, often work alongside the gear rack to detect obstacles and prevent accidents.

Additionally, the gear rack's robust construction and corrosion-resistant treatments make it suitable for outdoor use in various environments, from residential properties to industrial facilities.

Additional information

| Edited by | Yjx |

|---|