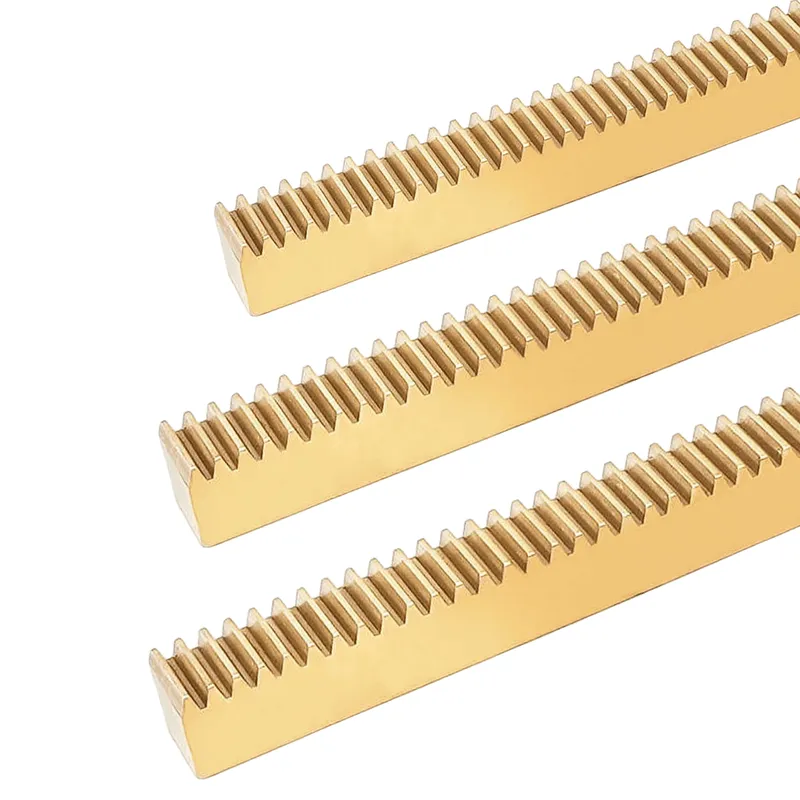

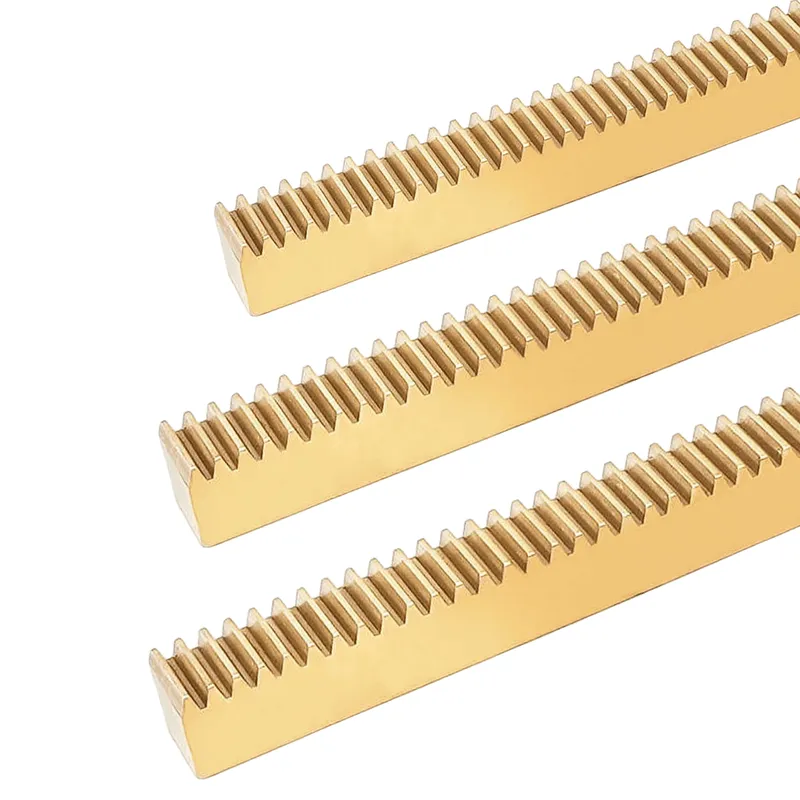

Brass Gear Racks

Brass material gear racks provide a long-lasting working life in corrosive and abrasive environments while also having the ability to be easily machined due to the softness of the material. More specifically, our brass gearing (racks and gears) is made from high-quality Ms58 (2.0401) brass and is manufactured using an overhead milling cutter. The teeth are made to a 20° pressure angle and are available in module 0.3 – 1 pitch options. However, we also supply brass gear racks in other pitches or pressure angles upon request.

Brass material gear racks provide a long-lasting working life in corrosive and abrasive environments while also having the ability to be easily machined due to the softness of the material. More specifically, our brass gearing (racks and gears) is made from high-quality Ms58 (2.0401) brass and is manufactured using an overhead milling cutter. The teeth are made to a 20° pressure angle and are available in module 0.3 - 1 pitch options. However, we also supply brass gear racks in other pitches or pressure angles upon request.

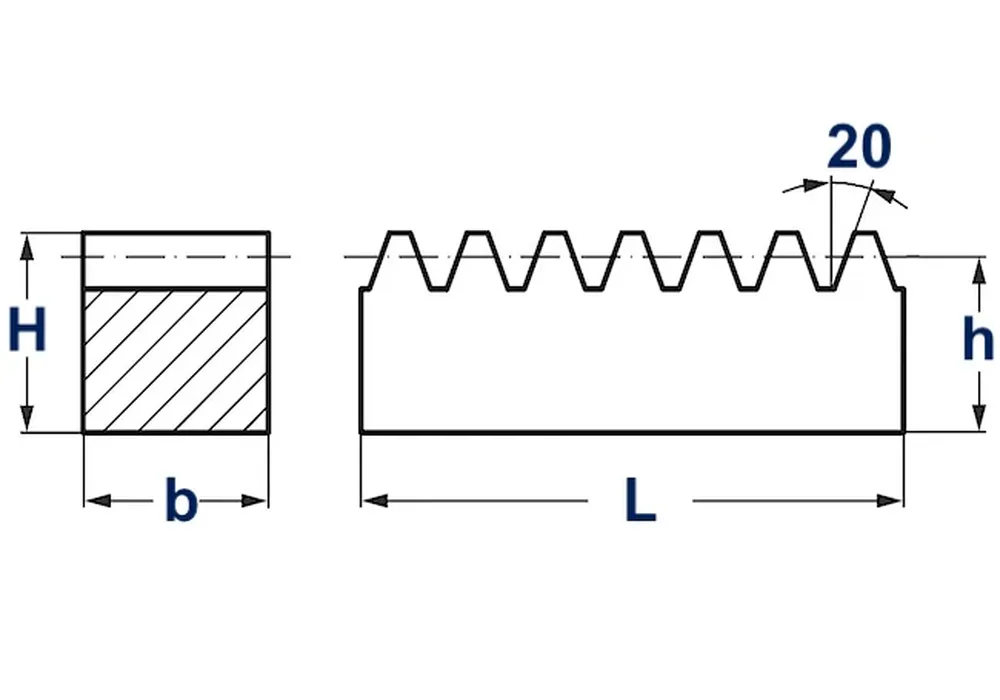

Brass Gear Rack Dimensions

|  |

| Part # | Module | Dimension (b) | Dimension (H) | Dimension (h) | Length (L) | Weight |

|---|---|---|---|---|---|---|

| 26060100 | 0.3 | 2mm | 4mm | 3.7mm | 250mm | 14 Grams |

| 26160100 | 0.5 | 2mm | 4mm | 3.5mm | 250mm | 14 Grams |

| 26260100 | 0.7 | 4mm | 6mm | 5.3mm | 250mm | 42 Grams |

| 26360000 | 1 | 7mm | 5mm | 4mm | 250mm | 56 Grams |

| 26360100 | 1 | 10mm | 8mm | 7.0mm | 230mm | 131 Grams |

| 26360300 | 1 | 10mm | 10mm | 9.0mm | 250mm | 184 Grams |

| 26360500 | 1 | 10mm | 10mm | 9.0mm | 500mm | 371 Grams |

Note: Due to the manufacturing method, Dimensions H and h are -0.2mm in tolerance.

Brass Gear Rack Design Features

Brass Gear Rack Applications

- Precision Machinery and Equipment

Brass gear racks are widely used in precision machinery where smooth and accurate motion is essential. Their high machinability and precise tooth design make them ideal for applications such as CNC machines, robotics, and automated systems requiring seamless linear motion control. - Aerospace and Marine Industries

In aerospace and marine environments, brass gear racks are favored for their excellent resistance to corrosion and wear. These properties allow them to perform reliably in harsh conditions involving exposure to saltwater, humidity, and temperature variations, ensuring long-term durability. - Medical and Laboratory Equipment

Medical and laboratory equipment, such as imaging devices and diagnostic machines, often incorporate brass gear racks due to their smooth operation and precision. The non-magnetic and corrosion-resistant nature of brass makes it suitable for sensitive and sterile environments where reliability is critical. - Food Processing and Packaging Systems

In the food processing industry, brass gear racks are utilized for their resistance to contamination and corrosion. They are commonly found in conveyor systems, packaging machines, and other automated equipment where hygiene, durability, and smooth operation are essential for efficiency. - Industrial Automation and Robotics

Brass gear racks play a crucial role in industrial automation and robotics systems, providing reliable linear motion for pick-and-place robots, automated assembly lines, and material handling systems. Their durability and precision enhance the performance and longevity of these advanced technologies. - Architectural and Decorative Applications

Brass gear racks are sometimes used in architectural systems, such as adjustable window mechanisms or decorative moving displays, due to their aesthetic appeal and functionality. The natural golden hue of brass, combined with its corrosion resistance, ensures both beauty and practicality in such applications.

|  |

| Gear Rack for Marine Systems | Gear Rack for Aerospace Systems |

|  |

| Gear Rack for Automotive Systems | Gear Rack for Automation and Robotics |

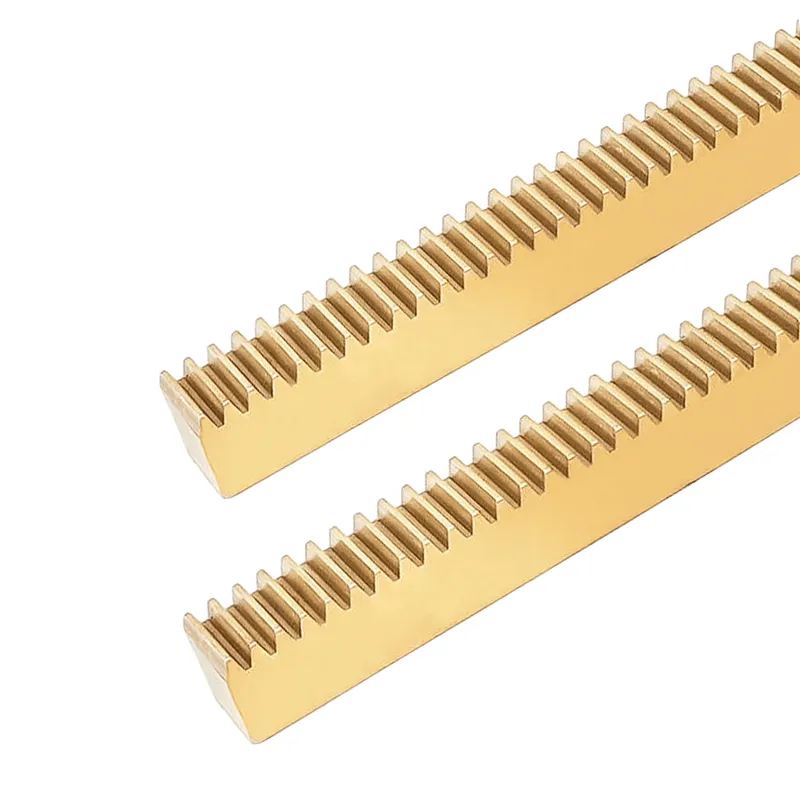

Brass Gear Rack vs. Stainless Steel Gear Rack

Brass gear racks and stainless steel gear racks differ significantly in material properties, performance characteristics, and applications. These differences make each type of gear rack suitable for specific operational environments and mechanical requirements.

Material Properties

Brass gear racks are made from an alloy of copper and zinc, such as Ms58 (2.0401), which is known for its excellent machinability, corrosion resistance, and aesthetic appeal. Brass is softer and less dense than stainless steel, making it easier to machine and more suitable for applications where precision and customizability are paramount. In contrast, stainless steel gear racks are made from a steel alloy containing chromium, which provides superior strength, wear resistance, and durability. Stainless steel is harder and more robust, making it ideal for high-load or high-stress applications.

Corrosion Resistance

Both materials have good corrosion resistance, but they are suited to different environments. Brass resists tarnishing and is excellent in mildly corrosive environments, such as those involving water or humidity. Stainless steel, particularly grades like 304 or 316, offers superior corrosion resistance in more aggressive environments, including exposure to saltwater, chemicals, and extreme temperatures.

Applications

Brass gear racks are commonly used in precision machinery, medical devices, and decorative systems due to their smooth operation, machinability, and aesthetic value. Stainless steel gear racks, on the other hand, are used in heavy-duty applications such as industrial equipment, marine environments, and food processing systems where high strength and hygiene standards are required.

|  |

| Brass Gear Rack | Stainless Steel Gear Rack |

Additional information

| Edited by | Yjx |

|---|