Curved Gear Racks

Curved gear rack is a rack with an arc profile, and its teeth are distributed on a section of an arc. It can be regarded as a linear rack bent into an arc around a center of a circle. Unlike the conversion of linear motion and rotational motion in ordinary rack transmission, Curved gear racks are usually used to achieve motion transmission or specific mechanical actions related to arc trajectories, and are often used in some mechanical devices that require special motion methods, such as arc conveying mechanisms of some automated production lines, specific indexing devices, etc.

Curved gear rack is a rack with an arc profile, and its teeth are distributed on a section of an arc. It can be regarded as a linear rack bent into an arc around a center of a circle. Unlike the conversion of linear motion and rotational motion in ordinary rack transmission, Curved gear racks are usually used to achieve motion transmission or specific mechanical actions related to arc trajectories, and are often used in some mechanical devices that require special motion methods, such as arc conveying mechanisms of some automated production lines, specific indexing devices, etc.

Curved Gear Rack Specifications

| Model Number | M1,M1.5,M2,M2.5,M3,M4,M5,M8,M12 and etc. |

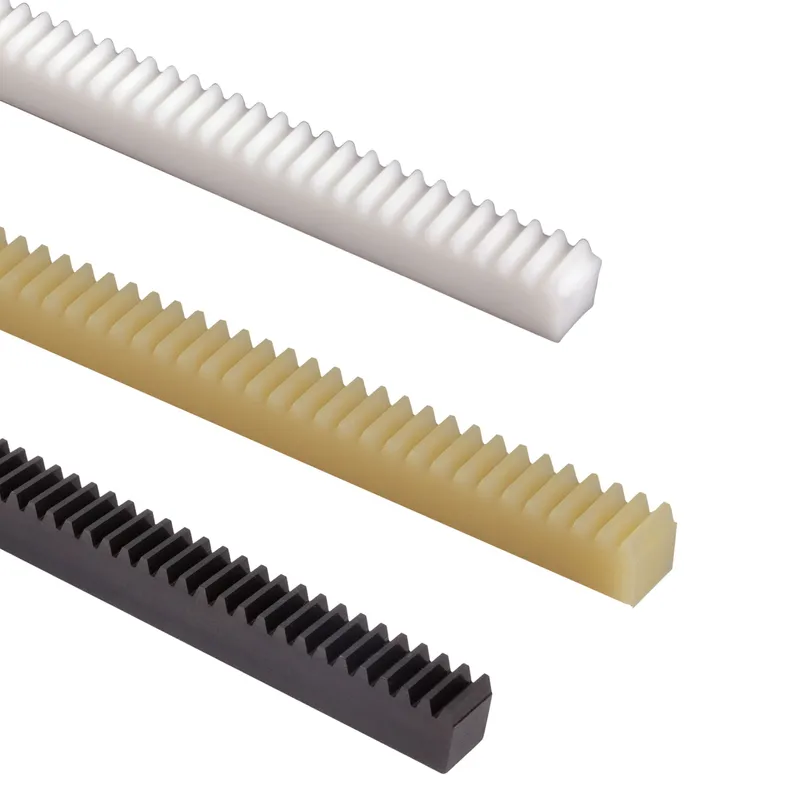

| Material | Brass, C45 steel, Stainless steel, Copper, POM, Aluminum, Alloy, and so on |

| Surface treatment | Zinc plated, Nickel plated, Passivation, Oxidation, Anodization, Geomet, Dacromet, Black Oxide, Phosphatizing, Powder Coating, and Electrophoresis |

| Standard | ISO, DIN, ANSI, JIS, BS and Non-standard. |

| Precision | DIN6,DIN7,DIN8,DIN9. |

| Teeth treatment | Hardened, Milled, or Ground |

| Tolerance | 0.001mm-0.01mm-0.1mm |

| Finish | shot/sand blast, heat treatment, annealing, tempering, polishing, anodizing, zinc-plated |

| Items packing | Plastic Cartons or Wooden Packaging |

| Payment terms | T/T, L/C |

| Production lead time | 20 business days for the sample,25 days for the bulk |

| Samples | Sample price range from $2 to $100. sample express request pay by clients |

| Applications | 1. Automatic controlling machine 2. Semiconductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

Advantages of Curved Gear Racks

- Facilitates Motion in Non-Linear Paths

Curved gear racks are specifically designed to enable movement along curved or circular trajectories, which straight racks cannot achieve. This makes them highly suitable for applications like sliding doors, robotic arms, and conveyor systems that require non-linear motion. - Compact Design for Space Efficiency

Curved gear racks allow for compact system designs by eliminating the need for additional components to guide curved motion. This efficient use of space is crucial for industries such as automotive, robotics, and aerospace, where minimizing size and weight is essential. - Precise and Smooth Motion Control

The teeth of curved gear racks are carefully designed to ensure smooth engagement with the pinion gear. This results in precise motion without jerking or slippage, which is critical for applications requiring high accuracy, such as CNC machines or surgical robots. - Enhanced Versatility for Complex Applications

Curved gear racks can be customized to fit a wide range of curvature profiles, making them versatile for use in complex systems. Whether the motion path requires an arc, full circle, or a specific radius, these racks provide tailored solutions for various industries. - Durable and Reliable in High-Stress Environments

Manufactured from robust materials like hardened steel or alloy, curved gear racks withstand heavy loads and continuous operation. Their durability makes them reliable for demanding environments, including industrial machinery, where consistent performance under stress is critical. - Reduces the Need for Additional Components

By directly creating curved motion paths, curved gear racks eliminate the need for auxiliary mechanisms like guide rails or curved tracks. This not only simplifies the overall design but also reduces maintenance and operational costs over time.

Curved Gear Rack Application Fields

- Automotive Steering Systems

Curved gear racks are integral to modern steering mechanisms, particularly in rack-and-pinion systems. They enable smooth and precise control of vehicles by converting the rotational motion of the steering wheel into the curved linear movement needed to turn the wheels effectively. - Robotics and Automation

In robotics, curved gear racks allow robots to perform complex tasks requiring motion along non-linear paths, such as welding, assembling, or painting. Their ability to facilitate precise and repeatable curved movements is essential for enhancing automation efficiency in industrial settings. - Sliding or Rotational Doors

Curved gear racks are commonly used in automatic sliding or rotational door systems. These racks enable controlled, smooth motion along an arc, making them ideal for revolving doors in commercial buildings, airports, and high-traffic public spaces. - Aerospace and Defense

In aerospace and defense applications, curved gear racks are used in systems like turret controls, radar positioning, and aircraft mechanisms. Their ability to handle high loads while maintaining precise curved motion is critical for the performance and reliability of these advanced systems. - Machinery and Equipment Positioning Systems

Curved gear racks are employed in heavy machinery for applications like positioning curved arms or adjusting components along an arc. They are vital in industries such as construction, mining, and manufacturing, where accurate and controlled movement is essential for productivity.

- heavy industries.

|  |

| Gear Rack for Automation and Robotics | Gear Rack for CNC Machine Tool |

|  |

| Gear Rack for Sliding Gate Openers | Gear Rack for Automotive Systems |

Curved Gear Rack Vs. Helical Gear Rack

Both curved gear racks and helical gear racks are essential in mechanical systems, but they are designed for distinct applications and offer unique advantages based on their geometry and functionality.

A curved gear rack is characterized by its non-linear, arc-like shape, making it ideal for applications requiring curved motion paths. These racks are utilized in systems where movement must follow a specific circular or radial trajectory. Commonly used in robotics, automotive steering systems, or sliding door mechanisms, curved gear racks are designed to provide precise motion along curved paths. Their ability to conform to non-linear geometries enables compact system designs, reducing the need for additional guiding mechanisms like tracks or rails. They typically handle applications requiring motion control along arcs or complete circles, making them a specialized choice for radial motion systems.

In contrast, a helical gear rack features teeth cut at an angle (helix) to the rack's axis, which allows for smoother and quieter operation compared to straight racks. Helical gear racks are straight in geometry and are commonly used in linear motion systems where high efficiency and low noise are critical. These racks excel in applications requiring high-speed linear motion or heavy load-carrying capabilities, such as conveyor systems, machine tools, and industrial robotics. The angled teeth of helical racks ensure better meshing with the pinion gear, reducing vibration and improving overall performance.

While curved gear racks are specialized for non-linear motion, helical gear racks are better suited for linear applications with a focus on smoothness, efficiency, and durability. Choosing between the two depends on the specific motion path (curved or straight) and the performance requirements of the application.

|  |

| Curved Gear Rack | Helical Gear Rack |

Additional information

| Edited by | Yjx |

|---|