Helical Gear Racks

A helical gear rack is a mechanical component used in motion control systems to convert rotary motion into linear motion or vice versa. It is essentially a straight bar with helically cut teeth that mesh seamlessly with a helical gear (pinion). Unlike a straight-cut rack, a helical gear rack has teeth cut at an angle to the rack’s axis, forming a helix shape. This angled tooth design allows for smoother and quieter operation, as the engagement between the rack and pinion teeth occurs gradually, reducing vibration and noise.

A helical gear rack is a mechanical component used in motion control systems to convert rotary motion into linear motion or vice versa. It is essentially a straight bar with helically cut teeth that mesh seamlessly with a helical gear (pinion). Unlike a straight-cut rack, a helical gear rack has teeth cut at an angle to the rack's axis, forming a helix shape. This angled tooth design allows for smoother and quieter operation, as the engagement between the rack and pinion teeth occurs gradually, reducing vibration and noise.

Helical gear racks are commonly used in high-speed, high-torque applications, such as in industrial machinery, automation systems, and robotics, where precision and efficiency are critical. Their ability to handle higher loads and provide better alignment makes them superior to straight racks in many scenarios.

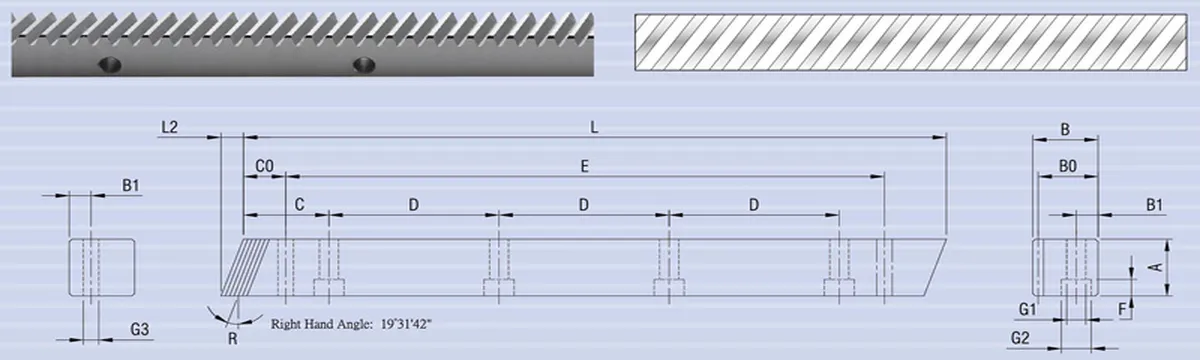

Helical Gear Rack Dimensions

| Module | L | L2 | Tooth No. | A | B | B0 | C | D | Hole No. | B1 | G1 | G2 | F | C0 | E | G3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.5 | 500.00 | 6 | 100 | 17 | 17 | 15.5 | 62.50 | 125 | 4 | 8 | 6 | 9.5 | 7 | 31.7 | 436.6 | 5.7 |

| 1.5 | 1000.00 | 6 | 200 | 17 | 17 | 15.5 | 62.50 | 125 | 8 | 8 | 6 | 9.5 | 7 | 31.7 | 936.6 | 5.7 |

| 2 | 500.00 | 8.5 | 75 | 24 | 24 | 22 | 62.50 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| 2 | 1000.0 | 8.5 | 150 | 24 | 24 | 22 | 62.50 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| 3 | 500.00 | 10.3 | 50 | 29 | 29 | 26 | 62.50 | 125 | 4 | 9 | 10 | 15 | 9 | 35.0 | 430.0 | 7.7 |

| 3 | 1000.0 | 10.3 | 100 | 29 | 29 | 26 | 62.50 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 |

| 4 | 506.67 | 13.8 | 38 | 39 | 39 | 35 | 62.50 | 125 | 4 | 12 | 10 | 15 | 9 | 33.3 | 433.0 | 7.7 |

| 4 | 1000.0 | 13.8 | 75 | 39 | 39 | 35 | 62.50 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 |

| 5 | 500.00 | 17.4 | 30 | 49 | 39 | 34 | 62.50 | 125 | 4 | 12 | 14 | 20 | 13 | 37.5 | 425.0 | 11.7 |

| 5 | 1000.00 | 17.4 | 60 | 49 | 39 | 34 | 62.50 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 |

| 6 | 500.00 | 20.9 | 25 | 59 | 49 | 43 | 62.50 | 125 | 4 | 16 | 18 | 26 | 17 | 37.5 | 425.0 | 15.7 |

| 6 | 1000.0 | 20.9 | 50 | 59 | 49 | 43 | 62.50 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 |

| 8 | 480.00 | 28.0 | 18 | 79 | 79 | 71 | 60.00 | 120 | 4 | 25 | 22 | 33 | 21 | 120.0 | 240.0 | 17.7 |

| 8 | 960.00 | 28.0 | 36 | 79 | 79 | 71 | 60.00 | 120 | 8 | 25 | 22 | 33 | 21 | 120.0 | 720.0 | 17.7 |

Advantages of Helical Gear Rack

- High transmission efficiency

The tooth surface of the helical gear has good contact and has good transmission efficiency. Compared with ordinary spur gear transmission, its transmission efficiency is usually higher. - Smooth operation

Due to the tooth design of the helical gear, the meshing process is smoother, reducing impact and vibration, so it runs relatively smoothly during operation and the noise is relatively small. - Strong load-bearing capacity

The helical gear has a large contact area and can withstand greater loads than the spur gear, making it suitable for working under heavy load conditions. - Self-centering

The helical gear rack has a certain self-centering ability during the meshing process, reducing the rolling defects caused by assembly errors, thereby improving the long-term working stability of the system. - Design flexibility

The combination of helical gear racks can be designed in various forms, which is convenient for realizing motion conversion in different directions and types, and meeting the needs of various applications. - Strong applicability

Because the parameter configuration of the helical gear can be adjusted, it is suitable for use in mechanical equipment with various transmission requirements, such as automation equipment, machine tools, robots, etc.

Helical Gear Rack Applications

- Industrial Automation and Robotics

Helical gear racks are widely used in industrial automation and robotics to achieve precise linear motion. Their smooth and quiet operation enables accurate positioning in robotic arms, pick-and-place machines, and conveyor systems, ensuring efficiency and reliability in automated processes. - CNC Machines and Machining Centers

In CNC machines, helical gear racks facilitate high-precision linear movement of cutting tools and workpieces. Their ability to handle high speeds and loads makes them ideal for maintaining accuracy in repetitive machining tasks, improving productivity and product quality. - Material Handling Equipment

Helical gear racks are essential in material handling systems like forklifts, cranes, and automated storage solutions. They provide the linear motion required for lifting, moving, or aligning loads, ensuring smooth operations even under heavy-duty conditions. - Railway and Transportation Systems

Used in railway track switches and other transportation mechanisms, helical gear racks ensure reliable movement and alignment. Their high torque capacity and durability make them suitable for handling the significant forces involved in transportation applications. - Energy and Power Generation Equipment

Helical gear racks play a role in renewable energy systems, such as solar trackers, allowing solar panels to follow the sun's movement. Their precision and ability to handle dynamic loads enhance energy efficiency and system performance over time. - Heavy Machinery and Construction Equipment

In heavy machinery like excavators, loaders, and cranes, helical gear racks are critical for linear actuation. Their robustness ensures the reliable transmission of force, enabling these machines to perform demanding tasks in construction and other heavy industries.

|  |

| Gear Rack for Automation and Robotics | Gear Rack for CNC Machine Tool |

|  |

| Gear Rack for Material Handling | Gear Rack for Construction Hoist Machinery |

Helical Gear Rack vs. Spur Gear Rack

The helical gear rack and spur gear rack are both mechanical components used to convert rotary motion into linear motion. However, they differ significantly in design, functionality, and applications.

- Tooth Design and Engagement

The primary difference lies in the tooth design. A spur gear rack has straight teeth cut perpendicular to its axis, while a helical gear rack has teeth cut at an angle, forming a helix. The angled teeth of the helical rack ensure that engagement between the rack and the pinion occurs gradually, with multiple teeth in contact at any given time. This results in smoother operation, reduced vibration, and quieter performance, as opposed to the more abrupt engagement of straight teeth in a spur gear rack. - Load Capacity and Efficiency

Helical gear racks can handle higher loads and torque due to their increased tooth contact area. This makes them suitable for demanding applications requiring strength and precision. Spur gear racks, while mechanically simpler and easier to manufacture, are better suited for low-speed, low-load operations where noise and vibration are not critical concerns. - Applications and Use Cases

Helical gear racks are commonly used in high-speed, high-precision systems such as CNC machines, robotics, and material handling equipment. Their ability to operate quietly and efficiently under higher loads makes them ideal for industrial automation. On the other hand, spur gear racks are often preferred in systems where simplicity, cost-effectiveness, and lower performance requirements are priorities, such as small mechanical devices or basic motion control systems.

|  |

| Helical Gear Rack | Spur Gear Rack |

Additional information

| Edited by | Yjx |

|---|