Steel Straight Bevel Gears Ratio 1.25:1 Straight Tooth System

The steel straight bevel gears ratio 1.25:1 straight tooth system refers to a type of mechanical gear setup where two bevel gears with straight teeth are used to transmit rotational motion and torque between intersecting shafts, typically at a 90-degree angle. The gear ratio of 1.25:1 indicates that for every 1.25 rotations of the driving gear (input), the driven gear (output) completes 1 full rotation. This ratio is often used in applications requiring a slight speed reduction or torque multiplication.

The steel straight bevel gears ratio 1.25:1 straight tooth system refers to a type of mechanical gear setup where two bevel gears with straight teeth are used to transmit rotational motion and torque between intersecting shafts, typically at a 90-degree angle. The gear ratio of 1.25:1 indicates that for every 1.25 rotations of the driving gear (input), the driven gear (output) completes 1 full rotation. This ratio is often used in applications requiring a slight speed reduction or torque multiplication.

The bevel gears are made of steel, providing durability, wear resistance, and the ability to handle high loads. The straight tooth design ensures simplicity and cost-efficiency, as it is easier to manufacture compared to spiral bevel gears. However, straight bevel gears can produce more noise and vibrations due to abrupt tooth engagement. They are commonly used in industrial machinery, automotive systems, and power tools where precise alignment and moderate speeds are critical.

Steel Straight Bevel Gear Ratio 1.25:1

|  |

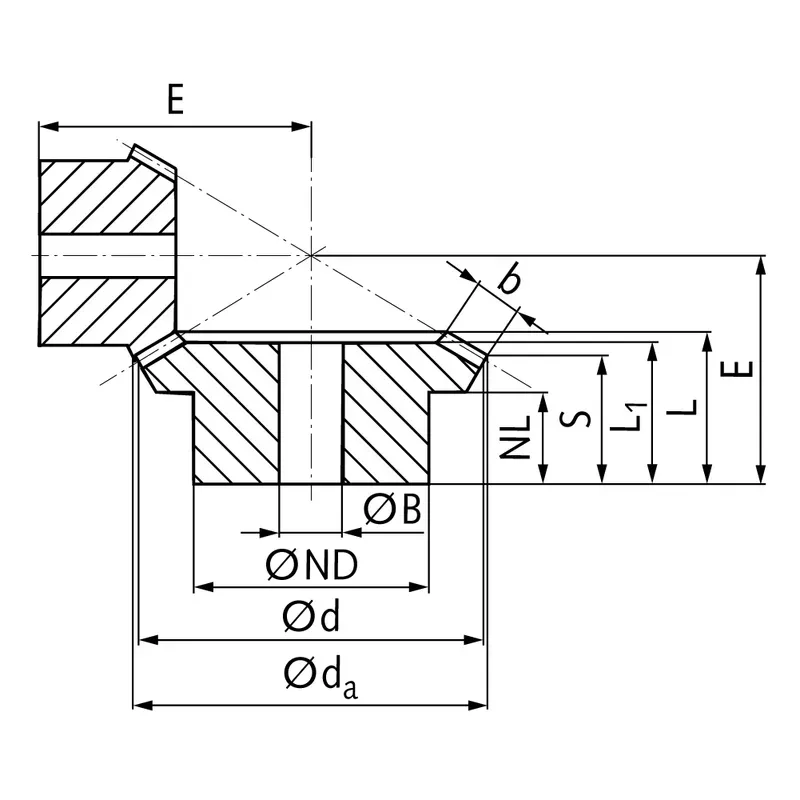

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 3 | 16 | 52,9 | 48 | 40 | 11,7 | 27 | 29,2 | 16,9 | 17 | 15 | 45 | 5,2 | 220 |

| 3 | 20 | 63,9 | 60 | 40 | 10,0 | 25 | 27,8 | 18,4 | 17 | 15 | 40 | 6,5 | 300 |

| 4 | 16 | 70,6 | 64 | 50 | 12,5 | 32 | 36,5 | 20,6 | 22 | 20 | 58 | 12,7 | 470 |

| 4 | 20 | 85,2 | 80 | 50 | 15,0 | 33 | 38,4 | 26,3 | 22 | 20 | 55 | 15,9 | 700 |

| 5 | 16 | 88,2 | 80 | 60 | 12,0 | 40 | 44,2 | 23,3 | 29 | 20 | 70 | 25,4 | 910 |

| 5 | 20 | 106,6 | 100 | 60 | 15,0 | 39 | 45,0 | 29,1 | 29 | 25 | 65 | 31,8 | 1300 |

Steel Straight Bevel Gear Design Features

- Straight Tooth Profile

The gear teeth are straight and cut along a conical surface, allowing for smooth engagement at intersecting shafts. This design is straightforward to manufacture and suitable for applications requiring simplicity, though it may generate higher noise levels during operation. - Material Strength and Durability

Made from high-grade steel, these gears are designed to handle heavy loads and extreme operating conditions. Steel provides excellent resistance to wear, deformation, and fatigue, ensuring reliable performance in demanding industrial and mechanical environments over extended periods. - 90-Degree Shaft Configuration

Straight bevel gears are specifically designed for transmitting power between shafts that intersect at right angles. This configuration is ideal for applications like automotive differentials, machine tools, and other systems requiring efficient torque transfer at angled intersections. - Precise Gear Ratio Control

The design allows for accurate gear ratio configurations, such as 1.25:1 or others, depending on the application. This precision ensures stable motion, reliable torque transfer, and predictable output, making it suitable for high-performance machinery and mechanical systems. - Compact and Lightweight Design

Steel straight bevel gears are typically compact and lightweight relative to their torque-handling capabilities. This design ensures they can fit into tight spaces without compromising performance, making them ideal for machinery where space constraints are a concern. - Cost-Effective Manufacturing

The straight tooth design simplifies the manufacturing process compared to spiral bevel gears. This cost-effective production method makes them an economical choice for various industries while still meeting the necessary performance and durability requirements for many standard applications.

Steel Straight Bevel Gear Applications

- Automotive Industry

Steel straight bevel gears are widely used in automotive systems, particularly in differentials and transmissions. They efficiently transfer torque between shafts at right angles, enabling reliable power delivery to wheels and ensuring smooth vehicle operation under varying load conditions. - Industrial Machinery

These steel bevel gears are integral to heavy-duty machinery such as conveyor systems, presses, and gearboxes. Their ability to handle high loads and transmit power effectively makes them essential for applications requiring durable and precise motion control in harsh industrial environments. - Aerospace Equipment

In aerospace applications, straight bevel gears are used in components like actuators and control systems. Their lightweight yet robust design ensures reliable performance under extreme conditions, such as high altitudes, temperature fluctuations, and intense mechanical stresses. - Power Tools and Equipment

Many power tools, such as drills, grinders, and saws, utilize steel straight bevel gears to transfer power from the motor to the tool head. Their compact design and efficient torque transmission make them ideal for handheld and portable equipment. - Agricultural Machinery

These straight bevel gears are extensively employed in farming equipment like tractors, plows, and harvesters. They facilitate power transmission in various mechanical systems, ensuring efficient operation in rugged conditions where durability and reliability are critical for prolonged use. - Marine and Offshore Applications

Steel bevel gears are commonly found in marine propulsion systems, winches, and cranes. Their corrosion-resistant steel construction and ability to handle heavy loads make them suitable for operating in harsh environments with constant exposure to moisture and salt.

|  |

| Bevel Gear for Automotive Differentials | Bevel Gear for Power Tools |

|  |

| Bevel Gear for Agricultural Machinery | Bevel Gear for Marine Industry |

Straight Bevel Gears vs Spiral Bevel Gears

Straight bevel gears and spiral bevel gears are two types of bevel gears, designed for transmitting power between intersecting shafts, usually at a 90-degree angle. However, they differ significantly in design, performance, and application.

1. Tooth Design and Engagement

Straight bevel gears have straight teeth that are cut along a conical surface. This straightforward design allows for direct and instantaneous tooth engagement. In contrast, spiral bevel gears have curved, oblique teeth that engage gradually, ensuring smoother meshing. This difference makes straight bevel gears noisier and more prone to vibration, while spiral bevel gears operate quieter and with less mechanical stress.

2. Load Capacity and Efficiency

Due to their gradual tooth engagement, spiral bevel gears distribute load more evenly across multiple teeth, allowing them to handle higher torque and loads compared to straight bevel gears. Straight bevel gears tend to concentrate stress on individual teeth during engagement, limiting their load-handling capabilities in high-demand applications.

3. Manufacturing Complexity and Cost

Straight bevel gears are simpler to manufacture because of their straightforward tooth geometry, making them more cost-effective. Spiral bevel gears, on the other hand, require advanced machining processes and greater precision, which increases manufacturing costs.

4. Applications

Straight bevel gears are suitable for low-speed, moderate-load applications where simplicity and cost are priorities, such as hand tools or basic machinery. Spiral bevel gears are preferred in high-speed, high-torque applications, such as automotive differentials, aerospace systems, and heavy industrial machinery, where performance and durability are critical.

|  |

| Straight Bevel Gears | Spiral Bevel Gears |

Additional information

| Edited by | Yjx |

|---|