Stainless Steel Bevel Gears Ratio 3:1 Straight-Tooth System

The stainless steel bevel gears ratio 3:1 straight-tooth system is a mechanical gear system designed for transferring motion and power between two shafts positioned at an angle, typically 90 degrees. These gears are made from durable stainless steel, which provides excellent resistance to corrosion, wear, and high temperatures, making them ideal for harsh environments and long-term use. This straight bevel gear system is commonly used in industrial machinery, automotive systems, and robotics, where precision, strength, and durability are crucial.

The stainless steel bevel gears ratio 3:1 straight-tooth system is a mechanical gear system designed for transferring motion and power between two shafts positioned at an angle, typically 90 degrees. These gears are made from durable stainless steel, which provides excellent resistance to corrosion, wear, and high temperatures, making them ideal for harsh environments and long-term use.

The 3:1 gear ratio means that for every three revolutions of the driving gear, the driven gear completes one revolution. This ratio allows for torque multiplication, making it suitable for applications requiring increased torque with reduced output speed. The straight-tooth design refers to the gear teeth being straight and positioned along the gear's face, rather than angled or spiral-shaped. While this design is simpler and easier to manufacture, it can generate more noise and experience higher stress compared to helical gears, especially at higher speeds.

This straight bevel gear system is commonly used in industrial machinery, automotive systems, and robotics, where precision, strength, and durability are crucial. Its stainless steel construction ensures longevity and reliability, even in demanding applications.

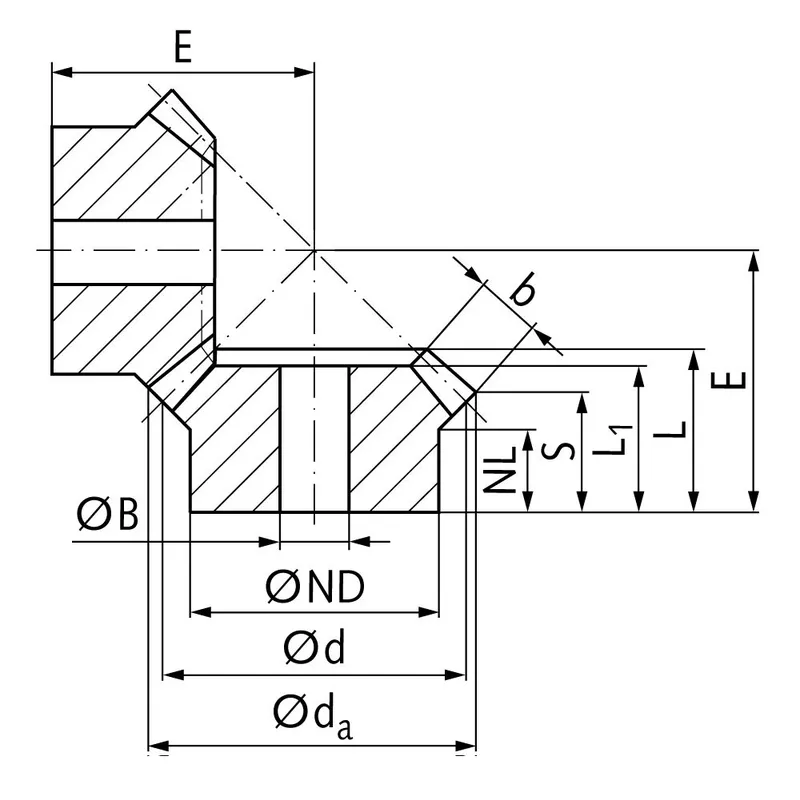

Stainless Steel Bevel Gear Ratio 3:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 15 | 17,7 | 15 | 13 | 9,2 | 16 | 16,5 | 10,0 | 7,1 | 5 | 32 | 0,10 | 14 |

| 1 | 45 | 45,4 | 45 | 25 | 10 | 15 | 17,0 | 15,1 | 7,1 | 8 | 22 | 0,30 | 92 |

| 1,5 | 16 | 28,0 | 24 | 18 | 11 | 22 | 23,2 | 12,7 | 11,4 | 8 | 48 | 0,45 | 42 |

| 1,5 | 48 | 72,6 | 72 | 50 | 12 | 20 | 24,1 | 20,8 | 11,4 | 15 | 32 | 1,35 | 405 |

| 2 | 16 | 35,9 | 32 | 20 | 10 | 25 | 26,6 | 12,6 | 15 | 10 | 60 | 1,21 | 80 |

| 2 | 48 | 97,3 | 96 | 60 | 18 | 30 | 35,0 | 31,0 | 15 | 25 | 45 | 3,63 | 95 |

| 2,5 | 16 | 44,9 | 40 | 30 | 15 | 34 | 36,5 | 17,8 | 20 | 10 | 77 | 2,6 | 200 |

| 2,5 | 48 | 121,6 | 120 | 80 | 15 | 29 | 33,9 | 28,5 | 20 | 25 | 46 | 7,8 | 1600 |

| 3 | 16 | 53,9 | 48 | 40 | 12,5 | 36 | 38,3 | 15,0 | 25 | 15 | 86 | 4,6 | 310 |

| 3 | 48 | 145,9 | 144 | 70 | 18 | 34 | 38,7 | 32,0 | 25 | 30 | 53 | 13,8 | 2300 |

| 4 | 16 | 71,8 | 64 | 50 | 17 | 46 | 48,3 | 20,3 | 30 | 20 | 115 | 9,4 | 680 |

| 4 | 48 | 194,6 | 192 | 90 | 20 | 43 | 50,0 | 41,9 | 30 | 30 | 70 | 28,2 | 5700 |

Benefits of Stainless Steel Straight Bevel Gears

- Corrosion Resistance

Stainless steel straight bevel gears, typically made from grades like AISI 303 or 316, resist rust and chemical degradation. This makes them ideal for harsh environments such as marine, food processing, or chemical industries, ensuring long-term reliability and minimal maintenance. - Durability and Strength

These stainless steel bevel gears offer high tensile strength and wear resistance due to stainless steel’s robust properties. They withstand heavy loads and prolonged use, making them suitable for demanding applications like industrial machinery, ensuring consistent performance without frequent replacements. - Precision in Motion Transfer

Straight-tooth bevel gears provide accurate transmission of rotational motion between intersecting shafts, often at 90 degrees. Their tooth geometry, modeled on standards like DIN 3967, ensures smooth engagement, reducing backlash and maintaining efficiency in precision-driven systems. - Hygienic Properties

Stainless steel’s non-porous surface resists bacterial growth, making these gears suitable for food, beverage, and pharmaceutical industries. They can endure frequent cleaning with harsh chemicals, maintaining compliance with strict hygiene standards while ensuring operational integrity. - Versatility in Applications

These bevel gears support 3:1 or other ratios, enabling speed reduction and torque increase. Used in conveyor systems, pumps, or automation equipment, their adaptability across industries stems from stainless steel’s ability to handle diverse environmental conditions effectively. - Low Maintenance Costs

Due to their corrosion resistance and durability, stainless steel bevel gears require minimal upkeep. This reduces downtime and replacement costs in applications like packaging or marine systems, offering cost-effective operation over extended periods with consistent performance.

Uses of Stainless Steel Bevel Gears

- Industrial Machinery and Equipment

Stainless steel bevel gears are widely used in industrial machinery for transmitting power between shafts at an angle. They are integral to manufacturing equipment, conveyor systems, and material-handling machines where durability, precision, and resistance to wear are essential. - Automotive and Transportation Systems

Bevel gears are critical in automotive applications, such as in differential systems, where they transfer torque between the drive shaft and the wheels. Their stainless steel construction ensures long-lasting performance, even under high torque and varying environmental conditions. - Marine and Offshore Applications

Due to their corrosion resistance, straight bevel gears are ideal for marine environments. They are used in ship steering systems, winches, and propulsion mechanisms, where exposure to saltwater and harsh weather demands high durability and reliable power transmission. - Aerospace and Aviation Components

Bevel gears play a crucial role in aerospace systems, including landing gear mechanisms, flight control systems, and engine components. Stainless steel gears are preferred for their ability to withstand extreme temperatures, high loads, and the demanding conditions of aviation environments. - Robotics and Automation Systems

In robotics, stainless steel bevel gears are used to achieve precise motion and angular power transmission in robotic arms, joints, and automated machinery. Their strength, precision, and corrosion resistance ensure consistent performance in high-precision, repetitive operations. - Food Processing and Medical Equipment

Stainless steel bevel gears are essential in food processing and medical equipment due to their non-corrosive and hygienic properties. They are used in mixers, conveyors, and sterilization systems, ensuring safe operation in environments where cleanliness and sanitation are critical.

|  |

| Bevel Gear for Automotive Industry | Bevel Gear for Marine Industry |

|  |

| Bevel Gear for Aerospace Industry | Bevel Gear for Food Industry |

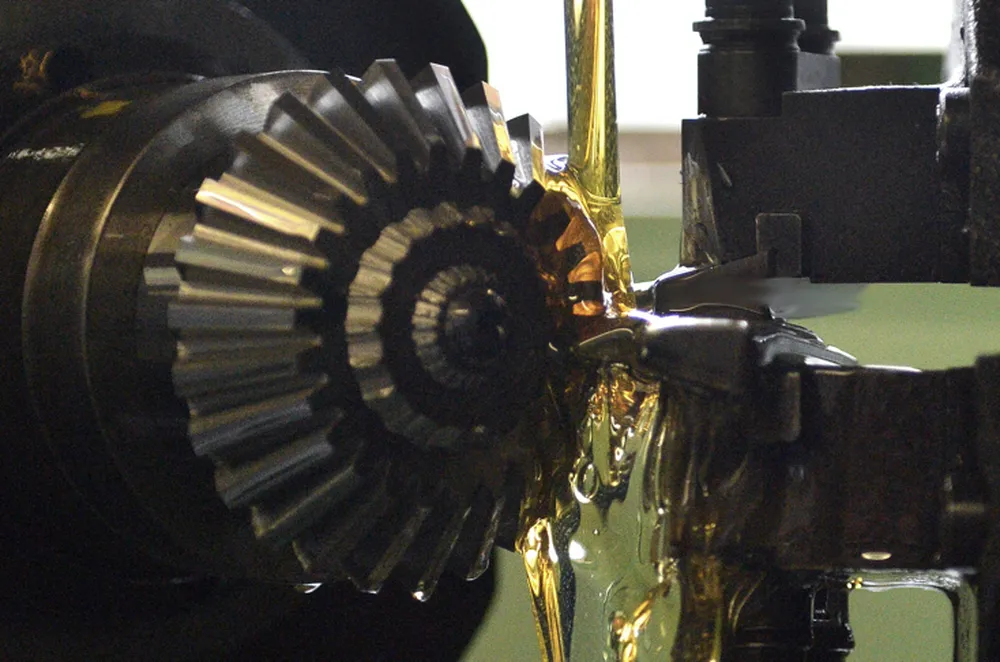

Straight Bevel Gear Maintenance and Lubrication

1. Select the Right Lubricant

Choose a high-quality lubricant specifically designed for straight bevel gears. Consider factors such as operating conditions, load, temperature, and speed when selecting the lubricant. Always follow the manufacturer’s recommendations for lubricant type and viscosity.

2. Regular Lubrication Schedule

Establish a regular lubrication schedule based on the gearbox’s operating conditions and the manufacturer’s recommendations. Regular lubrication helps reduce friction, wear, and heat generation, thereby improving gear efficiency and extending their service life.

3. Monitor Oil Quality

Regularly monitor the quality of the lubricating oil, including its cleanliness and viscosity. Contaminated or degraded oil can cause premature wear and damage to gears. Replace the oil if it becomes contaminated or loses its proper viscosity.

4. Lubricate at Operating Temperature

Ideally, lubricate the gears when they are at their operating temperature. This ensures that the lubricant reaches all critical areas and provides optimal lubrication during actual working conditions.

5. Maintain Proper Oil Levels

Ensure that the gearbox has the correct oil level to provide adequate lubrication to all gears. Too much or too little oil can lead to inefficient lubrication and potential gear damage.

6. Check Gear Alignment

Regularly inspect and maintain proper gear alignment to prevent uneven loading and excessive wear on the gear teeth. Misalignment can lead to increased friction and decreased gear performance.

7. Monitor Gear Wear

Periodically inspect the gear teeth for signs of wear, such as pitting, scoring, or chipping. If any damage is detected, address the issue promptly to avoid further deterioration and potential gearbox failure.

8. Avoid Overloading

Ensure that the gearbox is not subjected to excessive loads beyond its designed capacity. Overloading can lead to accelerated gear wear and premature failure.

9. Implement Vibration Analysis

Use vibration analysis techniques to monitor the gearbox for potential issues. Abnormal vibration patterns can indicate misalignment or gear damage, allowing for early detection and preventive measures.

10. Regular Maintenance and Inspection

Perform regular maintenance and inspection of the gearbox and straight bevel gears. Address any issues promptly and conduct repairs or replacements as needed.

Additional information

| Edited by | Yjx |

|---|