Steel Spiral Bevel Gears Ratio 4:1 Spiral Tooth System

The steel spiral bevel gears ratio 4:1 spiral tooth system is a mechanical gear arrangement designed to transfer torque and rotational motion between shafts that are typically set at a 90-degree angle. The spiral tooth system refers to the curved, helical design of the gear teeth, which enhances contact between the gears, providing smooth and quiet operation with reduced vibration. This design is ideal for high-speed and high-load applications such as automotive differentials, industrial machinery, and aerospace systems, where precision, durability, and efficiency are critical.

The steel spiral bevel gears ratio 4:1 spiral tooth system is a mechanical gear arrangement designed to transfer torque and rotational motion between shafts that are typically set at a 90-degree angle. These gears are made of durable steel and are precision-engineered to ensure high performance in demanding applications. The 4:1 gear ratio means that the driving gear (pinion) completes four revolutions for every one revolution of the driven gear, effectively reducing speed while increasing torque.

The spiral tooth system refers to the curved, helical design of the gear teeth, which enhances contact between the gears, providing smooth and quiet operation with reduced vibration. This design is ideal for high-speed and high-load applications such as automotive differentials, industrial machinery, and aerospace systems, where precision, durability, and efficiency are critical.

Steel Spiral Bevel Gear Ratio 4:1

|  |

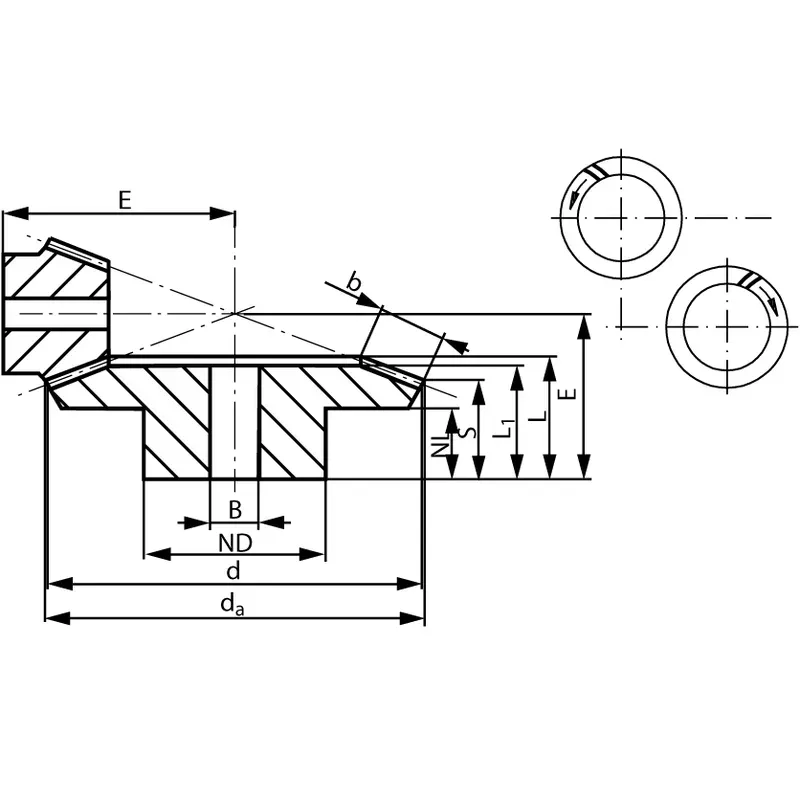

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 16 | 25,9 | 24 | 20 | 7,3 | 21 | 21,8 | 8,2 | 14 | 8 | 56 | 7,8 | 842 |

| 1 | 64 | 96,5 | 96 | 70 | 8 | 19 | 22,4 | 19 | 14 | 20 | 30 | 31,2 | 842 |

| 1,5 | 11 | 27,8 | 24,2 | 20 | 8 | 19 | 20,7 | 9 | 12 | 8 | 57 | 11,3 | 775 |

| 1,5 | 44 | 97,3 | 96,8 | 70 | 8 | 17 | 21,9 | 19 | 12 | 20 | 30 | 45,2 | 775 |

Steel Spiral Bevel Gear Design Benefits

- Enhanced Load Capacity

Steel spiral bevel gears feature curved teeth that distribute contact over a larger area compared to straight bevel gears. This design reduces stress concentration, allowing the gears to handle higher loads and torque, making them ideal for heavy-duty applications like industrial machinery and automotive systems. - Smoother and Quieter Operation

The spiral tooth design ensures gradual tooth engagement, minimizing impact and vibration during operation. This results in quieter performance, which is critical in applications such as precision machinery or vehicle differentials, where noise reduction improves user experience and system longevity. - Improved Efficiency in Power Transmission

The curved teeth of spiral bevel gears provide a rolling contact that enhances meshing efficiency. This reduces energy loss and heat generation, enabling efficient power transfer between intersecting shafts, particularly in high-speed applications like aerospace or manufacturing equipment. - Durability Through Material Strength

Constructed from high-strength carbon or alloy steels and often heat-treated, these gears resist wear and fatigue under demanding conditions. Their robust construction ensures a long service life, making them suitable for continuous operation in harsh industrial environments. - Versatility in High-Torque Applications

The 4:1 gear ratio and spiral design allow these steel bevel gears to effectively manage high torque at reduced speeds. This makes them versatile for applications like heavy machinery, where precise control and substantial power transmission are required. - Better Misalignment Tolerance

Spiral bevel gears can accommodate slight shaft misalignments due to their curved tooth geometry. This flexibility reduces the risk of premature wear or failure, enhancing reliability in systems where perfect alignment is challenging, such as complex drivetrains.

Spiral Bevel Gears vs. Straight Bevel Gears

|  |

| Spiral Bevel Gears | Straight Bevel Gears |

Steel Bevel Gear Examples and Applications

- Automotive Industry

Steel spiral bevel gears are widely used in automotive differentials to transfer power from the drive shaft to the wheels. Their ability to handle high torque and provide smooth, quiet operation makes them essential for improving vehicle performance, efficiency, and durability. - Aerospace Industry

In aerospace applications, steel spiral bevel gears are utilized in helicopter transmissions, jet engines, and flight control systems. Their compact design, high strength, and precision ensure reliable power transmission under extreme conditions, including high-speed operations and significant temperature variations. - Industrial Machinery

Industrial machines such as conveyors, mixers, and compressors rely on spiral bevel gears for torque transmission in heavy-duty settings. Their ability to handle high loads with minimal vibration makes them ideal for ensuring the longevity and efficiency of critical equipment in manufacturing plants. - Power Generation

Spiral bevel gears are integral to power generation equipment, including wind turbines and hydroelectric generators. Their efficiency in transmitting power at high speeds and their durability under heavy loads make them indispensable for energy production systems that demand long-term reliability. - Mining and Construction Equipment

Large-scale mining and construction machinery, such as excavators and crushers, employ steel spiral bevel gears to manage rugged operations. Their robust construction and ability to distribute load evenly allow them to withstand the intense stress and demanding conditions of these industries. - Marine Industry

In marine applications, spiral bevel gears are used in ship propulsion systems and offshore equipment. Their corrosion-resistant steel construction and ability to handle high torque ensure efficient and reliable operation, even in harsh marine environments with exposure to saltwater and high humidity.

|  |

| Bevel Gear for Robotics | Bevel Gear for Marine Industry |

|  |

| Bevel Gear for Automotive Industry | Bevel Gear for Agricultural Machinery |

Additional information

| Edited by | Yjx |

|---|