Support Leg Hydraulic Cylinder for Truck Crane

The support leg hydraulic cylinder for a truck crane is a critical component designed to provide stability and balance during crane operations. It is a hydraulic actuator that powers the extension and retraction of the support legs, also known as outriggers, which are deployed to stabilize the crane while lifting heavy loads. These cylinders use pressurized hydraulic fluid to generate the force needed to move the legs into position, ensuring the crane remains steady even on uneven terrain.

The support leg hydraulic cylinder for a truck crane is a critical component designed to provide stability and balance during crane operations. It is a hydraulic actuator that powers the extension and retraction of the support legs, also known as outriggers, which are deployed to stabilize the crane while lifting heavy loads. These cylinders use pressurized hydraulic fluid to generate the force needed to move the legs into position, ensuring the crane remains steady even on uneven terrain.

Typically constructed from high-strength materials like steel, these hydraulic support leg cylinders are engineered to handle extreme loads and environmental conditions. They feature precise seals to prevent fluid leakage and maintain consistent performance. The support leg hydraulic cylinder is vital for the safety and efficiency of crane operations, preventing tipping or structural damage during heavy lifting tasks.

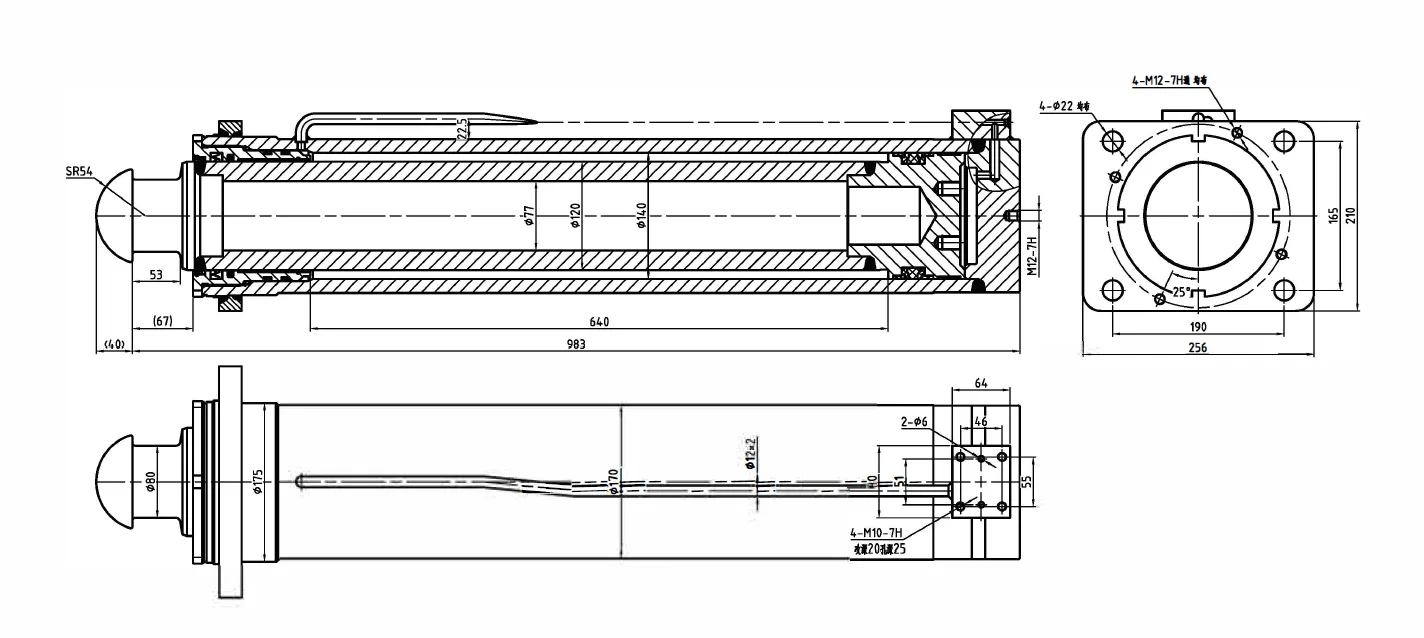

Support Leg Hydraulic Cylinder Dimensions

|

|

|

|

| Hydraulic Support Leg Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMNYY11112025 | Φ80XΦ60X790 | 18MPa | 27MPa | 790 | 1112 | 45kg |

| Product Name: | Support Leg Hydraulic Cylinder |

| Function: | Supporting function. |

| Cylinder diameter: | 63mm-150mm |

| Rod diameter: | 45mm-120mm |

| Travel: | 600mm-200mm |

| Maximum pressure Mpa: | 20MPa |

| Maximum thrust KN: | 353KN |

Truck Crane Hydraulic Cylinder Types

- Hydraulic Luffing Cylinders

Hydraulic luffing cylinders control the vertical movement of a truck crane’s boom, enabling precise angle adjustments for lifting loads. Constructed with high-strength steel, they handle immense pressures, ensuring smooth operation. These cylinders use hydraulic fluid to extend or retract, offering reliable performance under heavy loads, critical for tasks requiring accurate boom positioning. - Hydraulic Horizontal Cylinders

Hydraulic horizontal cylinders manage the lateral or slewing motion of the crane’s boom, facilitating side-to-side movement. Built for durability, they withstand torsional forces and harsh environments. These cylinders ensure precise control, enhancing operational efficiency during load positioning, with robust seals to prevent hydraulic leaks. - Hydraulic Counterweight Cylinders

Hydraulic counterweight cylinders adjust the crane’s counterweight to balance heavy loads, preventing tipping. Made from reinforced materials, they provide controlled extension and retraction, optimizing stability. These cylinders are vital for maintaining equilibrium during lifting, with high-pressure resistance ensuring safety in demanding conditions. - Hydraulic Support Leg Cylinders

Hydraulic support leg cylinders, or outrigger cylinders, extend and retract the crane’s stabilizing legs, creating a wider base for enhanced stability. Constructed with durable steel and reliable seals, they handle high loads, ensuring safe operation by distributing weight and preventing crane tip-overs.

Truck Crane Support Leg Hydraulic Cylinder Components

- Cylinder Barrel

The hydraulic cylinder barrel is a seamless, high-strength steel tube that houses the piston and hydraulic fluid. It endures extreme internal pressures during outrigger extension, maintaining structural integrity. Precision-engineered for durability, it resists corrosion, wear, and deformation in harsh crane operating conditions, ensuring long-term reliability. - Piston

The hydraulic cylinder piston is a vital component sliding within the cylinder barrel, transforming hydraulic pressure into linear force for outrigger movement. Crafted from robust materials, it ensures smooth, precise extension and retraction. Its tight tolerances prevent fluid leaks, enhancing operational reliability and support leg stability. - Piston Rod

The hydraulic cylinder piston rod extends from the piston, transferring force to the outrigger for stabilization. Made from hardened, chrome-plated steel, it resists bending, corrosion, and heavy loads. Its polished surface reduces seal wear, ensuring consistent performance and durability during repeated extension-retraction cycles. - Seals

Hydraulic cylinder seals are critical for preventing hydraulic fluid leaks, maintaining cylinder pressure. Constructed from high-grade rubber or polyurethane, they withstand high pressures, extreme temperatures, and wear. These seals ensure efficient, leak-free operation, extending the support leg cylinder’s lifespan and minimizing maintenance requirements. - End Caps

Hydraulic cylinder end caps seal both ends of the cylinder barrel, guiding the piston rod and containing hydraulic fluid. Made from durable steel, they resist high pressures and external impacts. Precision-machined for a secure fit, they enhance cylinder reliability, safety, and consistent outrigger performance. - Hydraulic Fluid Ports

Hydraulic fluid ports facilitate fluid entry and exit, controlling piston movement for outrigger operation. Strategically placed on the barrel, they ensure efficient, high-pressure fluid flow. Built from corrosion-resistant materials, they maintain structural integrity, supporting reliable and consistent support leg functionality.

Truck Crane Hydraulic Support Leg Cylinder Installation

- Prepare the Installation Area: Begin by parking the truck crane on a flat, stable surface to ensure safety and proper alignment during the installation process. Depressurize the hydraulic system completely to prevent unexpected fluid leaks or movement. Inspect the mounting points thoroughly to ensure they are clean, free of debris, and properly aligned for cylinder attachment. Gather all necessary tools, components, and hardware needed for the installation.

- Position the Hydraulic Cylinder: Carefully lift and position the hydraulic support leg cylinder near its designated mounting brackets. Ensure the cylinder is aligned precisely with the mounting points to avoid misalignment during operation. Confirm that the piston rod is oriented in the correct direction for movement and that the hydraulic ports face the proper direction for hose connections.

- Secure the Cylinder to Mounting Brackets: Attach the support leg hydraulic cylinder securely to the crane's mounting brackets using bolts, pins, or other fasteners provided. Insert the fasteners through the designated holes, ensuring proper alignment to eliminate unnecessary stress on the mounting brackets. Tighten all fasteners to the manual’s recommended torque specifications using calibrated tools.

- Connect Hydraulic Hoses: Attach the hydraulic hoses to the cylinder’s inlet and outlet ports, ensuring precise alignment to avoid cross-threading or damage to the fittings. Use appropriate seals and fittings to prevent fluid leaks during operation, and tighten the connections according to recommended specifications. Route the hoses carefully to avoid sharp bends, kinks, or potential damage from moving parts.

- Test for Proper Functionality: Re-pressurize the hydraulic system and activate the support leg cylinder to test its extension and retraction functions. Observe the cylinder's movement for smoothness and full range of motion. Check for hydraulic fluid leaks around the connections and fittings, as well as any unusual noises during operation.

|

|

Additional information

| Edited by | Yjx |

|---|