Counterweight Hydraulic Cylinder for Truck Crane

A counterweight hydraulic cylinder for a truck crane is a specialized hydraulic component designed to manage the positioning and stabilization of counterweights, which are critical for maintaining the crane’s balance and preventing tipping during lifting operations. These cylinders convert hydraulic pressure into linear force to adjust, extend, or retract counterweights, typically located at the rear of the crane, to offset the load’s weight on the boom or jib.

A counterweight hydraulic cylinder for a truck crane is a specialized hydraulic component designed to manage the positioning and stabilization of counterweights, which are critical for maintaining the crane’s balance and preventing tipping during lifting operations. These cylinders convert hydraulic pressure into linear force to adjust, extend, or retract counterweights, typically located at the rear of the crane, to offset the load’s weight on the boom or jib.

Made of high-strength steel, they withstand intense pressure and heavy loads, ensuring precise control and stability. The hydraulic counterweight cylinder operates within the crane’s hydraulic system, using pressurized fluid to move a piston, which facilitates the counterweight’s movement. Proper maintenance, including regular inspections for leaks or seal damage, is essential to ensure reliable performance and safety during heavy lifting tasks.

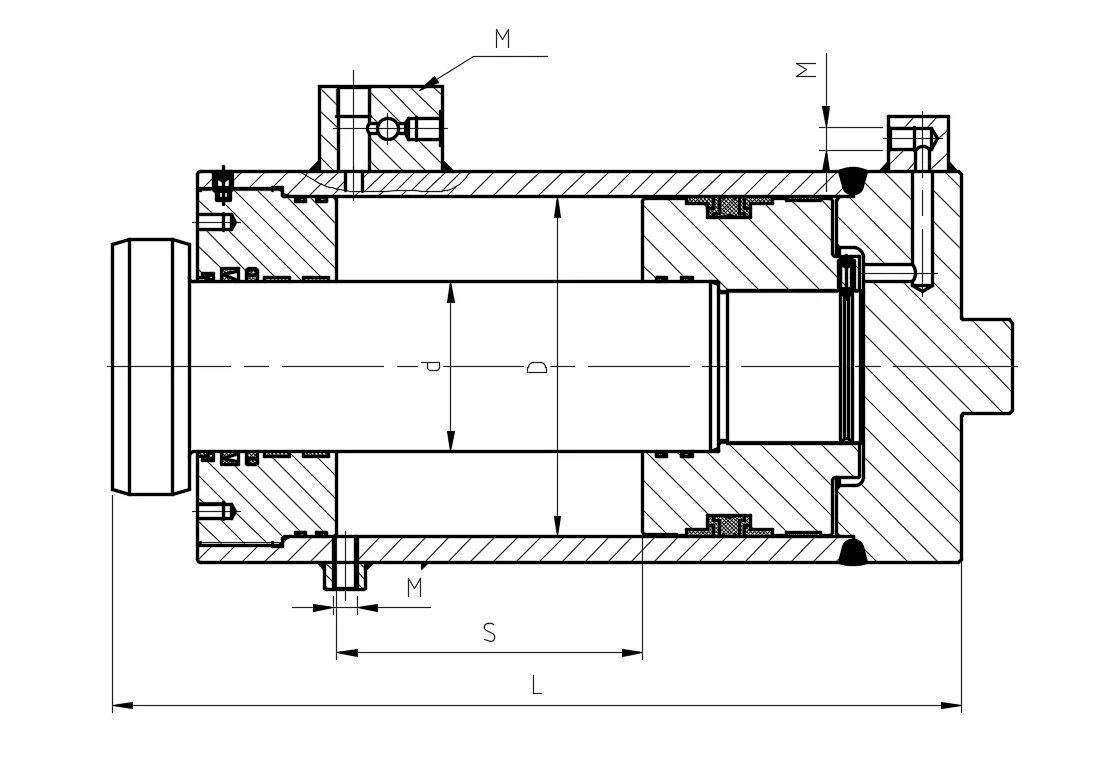

Counterweight Hydraulic Cylinder Dimensions

| Hydraulic Counterweight Cylinder |

|||||||

| Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| QAY220.12/13A-00 | Φ200 | Φ100 | 180 | 530 | 25MPa;40MPa | 3-G1/4;M20*1.5;2-M14*1.5 | 124kg |

| Product Name: | Counterweight Hydraulic Cylinder |

| Function: | Control the action of the counterweight. |

| Cylinder diameter: | 160mm-180mm |

| Rod diameter: | 90mm-150mm |

| Travel: | 180mm-400mm |

| Maximum pressure: | 25MPa |

| Maximum thrust: | 1540KN |

Truck Crane Hydraulic Cylinder Types

- Counterweight Hydraulic Cylinders

Counterweight hydraulic cylinders are designed to adjust and secure the counterweights of truck cranes. These cylinders ensure proper weight distribution, which stabilizes the crane during heavy lifting operations. They are built to handle extreme loads and high hydraulic pressure, ensuring operational safety and balance. Their robust design, combined with corrosion-resistant materials, allows them to perform efficiently in challenging environments. - Luffing Hydraulic Cylinders

Luffing hydraulic cylinders are responsible for adjusting the angle of the crane's boom. By controlling the boom's movement, these cylinders enable precise positioning of the load. They are engineered for smooth and steady performance, ensuring maximum accuracy during operations. Their durability and ability to handle varying loads make them critical components in truck cranes. - Horizontal Hydraulic Cylinders

Horizontal hydraulic cylinders are used to adjust or control the horizontal movement of specific crane components, such as telescoping sections. These cylinders provide power and precision to extend or retract parts of the crane. They ensure smooth linear motion to optimize the crane's reach and adaptability. Their rugged construction ensures stability and long-term performance under demanding conditions. - Support Leg Hydraulic Cylinders

Support leg hydraulic cylinders extend and retract the stabilizing legs of the truck crane. These cylinders provide the crane with a stable base during lifting operations, preventing tipping or instability. They are designed to handle the significant forces exerted by the crane and its load. Their reliability and strength are essential for ensuring safety and balance during operations.

Truck Crane Counterweight Hydraulic Cylinder Design Features

- Robust Construction

Counterweight hydraulic cylinders are built using high-strength materials such as alloy steel to withstand extreme pressures and heavy loads. This ensures long-term durability and reliable performance, even in harsh working environments. - High-Precision Control

These cylinders are designed to provide precise control over counterweight movement, enabling accurate load balancing. This feature is critical for maintaining crane stability and ensuring safe lifting operations in dynamic conditions. - Compact Design

The hydraulic counterweight cylinders are engineered with a compact yet powerful design to fit seamlessly within the crane’s structure. This minimizes space usage while maximizing performance, allowing for efficient operation in constrained setups. - Advanced Sealing Systems

Equipped with high-quality sealing technology, these truck crane counterweight hydraulic cylinders prevent hydraulic fluid leaks and ensure consistent performance. The seals also protect internal components from contamination, extending the cylinder's service life and reliability. - High Load-Bearing Capacity

Counterweight hydraulic cylinders are designed to handle significant loads without deformation or failure. They are tested for extreme pressure conditions, ensuring they can support heavy counterweights effectively during demanding tasks. - Corrosion Resistance

These truck crane hydraulic cylinders often feature surface treatments such as chrome plating to resist corrosion and wear. This ensures reliable operation in outdoor environments where exposure to moisture and harsh elements is common.

Truck Crane Hydraulic Cylinder Application Fields

- Construction and Infrastructure Projects

Truck crane hydraulic cylinders are essential in heavy-duty operations like lifting steel beams, concrete blocks, and other materials during the construction of buildings, bridges, and infrastructure. Their precision ensures safety and efficiency in handling loads. - Oil and Gas Industry

These hydraulic cylinder for cranes are widely used in the oil and gas sector for lifting and positioning equipment such as pipelines and drilling components. Their robust construction allows them to perform reliably in high-pressure and harsh environments. - Ports and Shipping Operations

Hydraulic cylinders are crucial for loading and unloading cargo, containers, and heavy machinery at ports. They enhance the operational efficiency of truck cranes, enabling quick and precise movement in busy shipping environments. - Mining and Quarrying

In mining operations, truck crane hydraulic cylinders are used to lift and position heavy mining equipment, machinery, and extracted materials. Their durability and load-bearing capacity are vital for managing extreme conditions and heavy loads. - Power and Energy Sectors

These hydraulic cylinder cranes assist in the installation and maintenance of power equipment, such as transformers and wind turbine components. Their ability to handle precise, heavy lifting makes them indispensable in renewable and conventional energy projects. - Emergency and Recovery Operations

Hydraulic cylinders are critical in rescue operations and vehicle recovery scenarios, where truck cranes are used to lift and remove debris, fallen structures, or overturned vehicles, ensuring efficiency and safety under critical conditions.

|

|

Additional information

| Edited by | Yjx |

|---|