Power Pin Hydraulic Cylinder for Truss Arm Crawler Crane

A power pin hydraulic cylinder for a truss arm crawler crane is a specialized hydraulic actuator designed to facilitate the secure connection and precise movement of the crane’s truss arm components. These crane hydraulic cylinders are critical for engaging or disengaging pivot pins that connect sections of the crane’s articulated arm, ensuring structural stability during heavy lifting operations. Typically, they feature robust construction with high-strength steel and advanced sealing systems to withstand dynamic loads and harsh environments.

A power pin hydraulic cylinder for a truss arm crawler crane is a specialized hydraulic actuator designed to facilitate the secure connection and precise movement of the crane’s truss arm components. These crane hydraulic cylinders are critical for engaging or disengaging pivot pins that connect sections of the crane’s articulated arm, ensuring structural stability during heavy lifting operations. Typically, they feature robust construction with high-strength steel and advanced sealing systems to withstand dynamic loads and harsh environments. These hydraulic power pin cylinders enhance operational efficiency and safety in construction, mining, and port applications.

Power Pin Hydraulic Cylinder Dimensions

| Product Name: | Power Pin Hydraulic Cylinder |

| Function: | Control the movement of the arm frame. |

| Cylinder diameter: | 50mm-125mm |

| Rod diameter: | 25mm-75mm |

| Travel: | 160mm-390mm |

| Maximum pressure: | 25MPa |

| Maximum thrust: | 307KN |

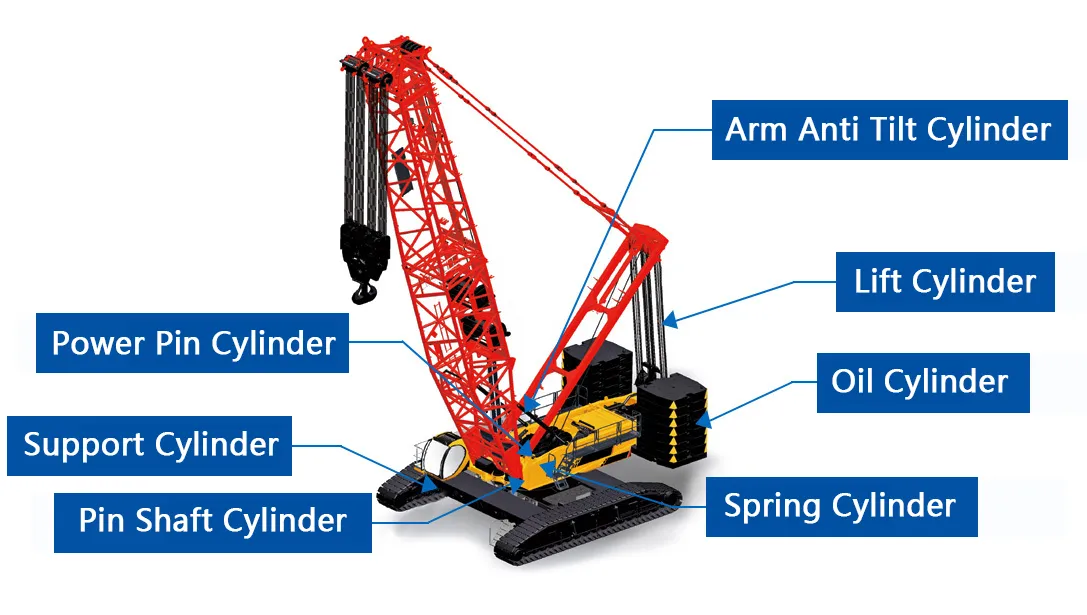

Truss Arm Crawler Crane Hydraulic Cylinder Types

- Hydraulic Lift Cylinders

Hydraulic lift cylinders are designed to provide vertical lifting power for the truss arm of crawler cranes. They enable the crane to raise and lower heavy loads with precision and stability. These cylinders are built with high tensile strength materials to endure immense loads and are equipped with advanced seals to prevent hydraulic fluid leakage during operations, ensuring efficiency and durability. - Hydraulic Support Cylinders

Hydraulic support cylinders are critical for stabilizing the truss arm and the entire crane during operation. These cylinders provide reliable support by maintaining the crane’s balance on uneven terrain. They are engineered to resist lateral forces and ensure that the crane remains steady, even under heavy operational stress, which enhances safety and performance in challenging environments. - Hydraulic Arm Anti-Tilt Cylinders

Hydraulic arm anti-tilt cylinders prevent the truss arm from tilting or misaligning during movement or lifting operations. These cylinders maintain the alignment of the arm, ensuring smooth and controlled operation. Their robust design minimizes the risk of structural failure, making them essential for maintaining the operational integrity and safety of the crane during complex maneuvers. - Hydraulic Pin Shaft Cylinders

Hydraulic pin shaft cylinders are used for locking and unlocking key joints of the truss arm. These cylinders provide precise control over pin adjustments, ensuring secure connections for enhanced operational stability. Their design focuses on durability and ease of maintenance, making them crucial for high-load operations where precise alignment and secure locking mechanisms are essential. - Hydraulic Spring Cylinders

Hydraulic spring cylinders are used to absorb shock and manage dynamic loads during crane operations. These cylinders provide cushioning to reduce stress on the crane’s structure, improving its longevity. They are especially important in applications involving repetitive movements, as they minimize vibrations and prevent excessive wear, ensuring a smoother and safer operation in demanding conditions. - Hydraulic Power Pin Cylinders

Hydraulic power pin cylinders are specialized components that facilitate the movement and locking of the crane’s power pins. These cylinders are vital for the secure positioning of the truss arm during heavy lifting. They are designed to handle extreme pressures and provide precise control, ensuring the crane operates safely and efficiently under varying load conditions. Their robust construction enhances reliability in harsh environments.

Truss Arm Crawler Crane Power Pin Hydraulic Cylinder Parts

- Cylinder Barrel

The hydraulic cylinder barrel is the main body of the hydraulic cylinder, housing the piston and hydraulic fluid. It is constructed from high-strength materials like alloy steel to withstand extreme pressures and external forces. Its interior is precision-machined to reduce friction and ensure smooth piston movement, which enhances the efficiency and durability of the hydraulic system during heavy-duty crane operations. - Piston and Piston Rod

The hydraulic cylinder piston is a crucial internal component that moves within the cylinder barrel, transferring hydraulic pressure into mechanical motion. Attached to the piston is the piston rod, which extends outward to connect with other crane components. The piston and rod are designed for high-performance operation, using wear-resistant materials and advanced coatings to endure constant stress and prevent corrosion over time. - Hydraulic Seals

Hydraulic cylinder seals are essential for preventing fluid leakage and ensuring efficient pressure containment within the cylinder. These include rod seals, piston seals, and wiper seals, all designed to handle high-pressure environments. They also protect the internal components from dirt, debris, and contaminants, which helps maintain the performance and longevity of the hydraulic cylinder in rugged working conditions. - End Caps

The hydraulic cylinder end caps are located at each end of the cylinder barrel, enclosing the hydraulic system and providing structural support. They house ports for hydraulic fluid entry and exit, facilitating pressure modulation for piston movement. End caps are built with precision to securely hold the cylinder’s internal components and withstand the immense forces generated during crane operations. - Hydraulic Ports

Hydraulic cylinder ports are critical for connecting the cylinder to the crane’s hydraulic system. These ports allow the controlled flow of hydraulic fluid into and out of the cylinder, enabling precise movement of the power pin. They are equipped with durable fittings and valves to ensure leak-proof connections and efficient fluid control, even under high-pressure conditions.

Power Pin Hydraulic Cylinder for Truss Arm Crawler Crane

A power pin hydraulic cylinder in a truss arm crawler crane is a specialized component critical for controlling the precise movement and positioning of the crane’s truss arm, which is a lattice-structured boom designed for stability and strength in heavy lifting operations. This type of hydraulic cylinder is typically used to secure and adjust the truss arm’s configuration, ensuring safe and efficient load handling. Here’s a detailed explanation of its function and operation.

The power pin hydraulic cylinder operates within the crane’s hydraulic system, which relies on pressurized hydraulic fluid (usually oil) to transmit power. The cylinder consists of a barrel, a piston connected to a rod, and seals to maintain pressure. It is designed to control the movement of the truss arm’s framework, often by locking or adjusting the position of the arm’s segments or pivot points. In a truss arm crawler crane, the power pin cylinder is often mounted at critical joints or pivot points, allowing the operator to adjust the arm’s angle or lock it for lifting.

When the crane operator activates the hydraulic system via control valves, a hydraulic pump pressurizes the fluid, which flows into the cylinder’s barrel through hoses. This pressure drives the piston, extending or retracting the rod to either engage or disengage the power pin, securing the truss arm’s position or allowing it to pivot. The cylinder’s buffering function minimizes shock during movement, enhancing stability. The system’s seals prevent fluid leaks, ensuring consistent pressure and reliable operation, even in harsh conditions like construction sites with dust or extreme temperatures.

Additional information

| Edited by | Yjx |

|---|