Pin Shaft Hydraulic Cylinder for Truss Arm Crawler Crane

A pin shaft hydraulic cylinder for a truss arm crawler crane is a specialized hydraulic actuator designed to facilitate precise movement and stability in the crane’s truss arm structure. This hydraulic pin shaft cylinder is integral to controlling the articulation and positioning of the truss arm, a lattice-like boom extension that enhances the crane’s reach and lifting capacity.

A pin shaft hydraulic cylinder for a truss arm crawler crane is a specialized hydraulic actuator designed to facilitate precise movement and stability in the crane’s truss arm structure. This hydraulic pin shaft cylinder is integral to controlling the articulation and positioning of the truss arm, a lattice-like boom extension that enhances the crane’s reach and lifting capacity. Connecting to the crane’s mounting points via pivot pins allows for slight rotational movement to maintain alignment and reduce mechanical stress, making it critical for heavy-duty lifting in construction and industrial applications.

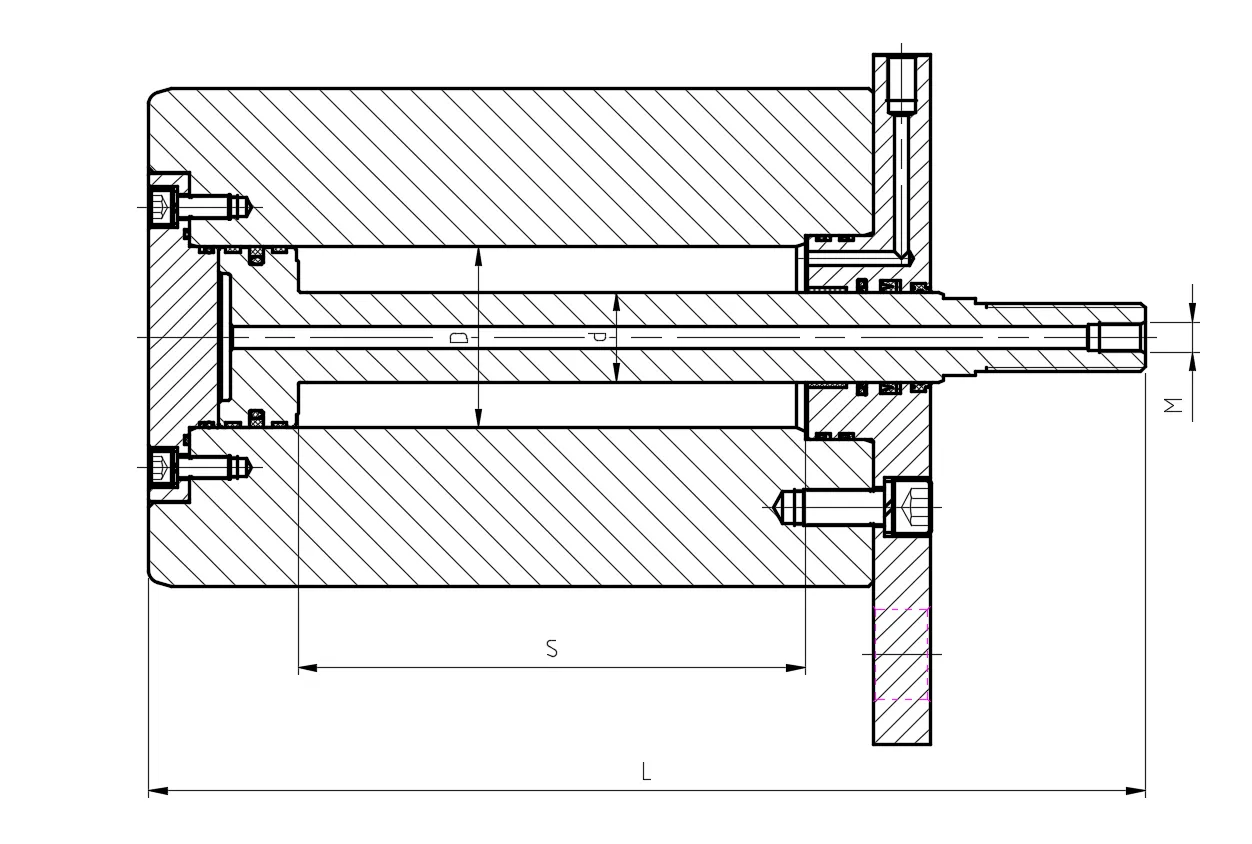

Pin Shaft Hydraulic Cylinder Dimensions

| Hydraulic Pin Shaft Cylinder |

|||||||

| Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| ZXYG14.01-00 | Φ80 | Φ40 | 225 | 440 | 25MPa | G1/4 | 97.8kg |

| Product Name: | Pin Shaft Hydraulic Cylinder |

| Function: | buffering effect |

| Cylinder diameter: | 80mm |

| Rod diameter: | 40mm |

| Travel: | 200mm-530mm |

| Maximum pressure: | 25MPa |

| Maximum thrust: | 125KN |

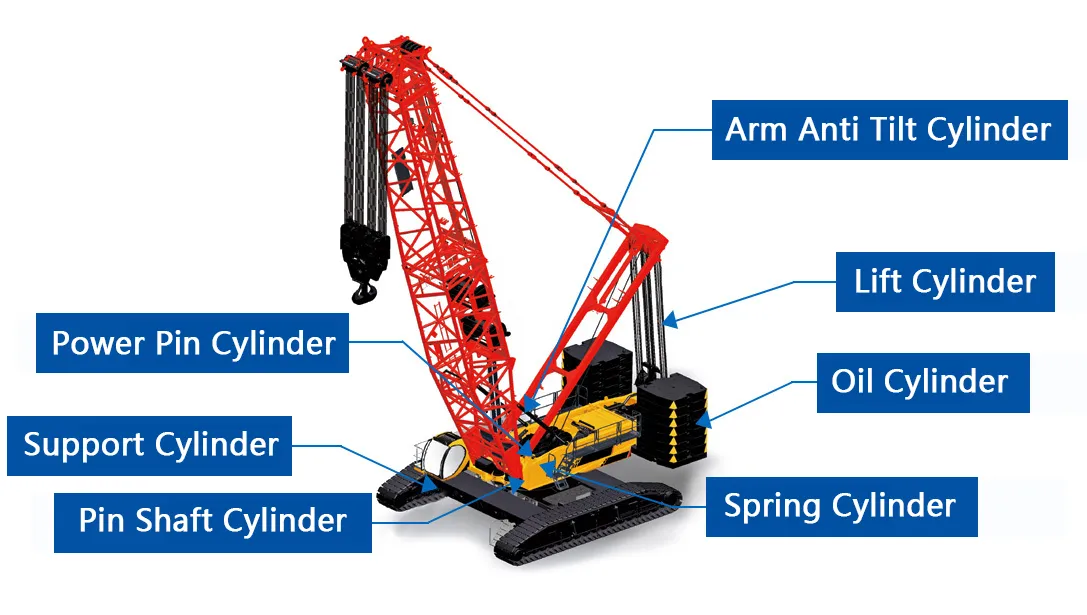

Truss Arm Crawler Crane Hydraulic Cylinder Types

- Support Hydraulic Cylinders

Support hydraulic cylinders are essential components in truss arm crawler cranes, providing stability and balance during operations. They are designed to withstand heavy loads, ensuring the crane remains steady even on uneven terrains. These cylinders facilitate the crane's ability to handle extreme forces by distributing weight evenly across the structure. - Lift Hydraulic Cylinders

Lift hydraulic cylinders are responsible for the vertical movement of the truss arm or boom in a crawler crane. They generate the force needed to lift and manipulate heavy loads with precision. These cylinders operate under high-pressure hydraulic systems, allowing smooth and controlled elevation. - Arm Anti-Tilt Hydraulic Cylinders

Arm anti-tilt hydraulic cylinders are crucial for maintaining the alignment and balance of the truss arm during operation. They prevent unwanted tilting or swaying of the arm, especially when handling asymmetrical loads. These cylinders enhance the crane’s stability and reduce the risk of accidents caused by uneven forces. - Pin Shaft Hydraulic Cylinders

Pin shaft hydraulic cylinders are pivotal in enabling rotational or angular motion of the crane’s truss arm. These cylinders are connected to the arm via a pin shaft, allowing precise control of angular positioning. They are engineered for heavy-duty performance and can handle significant stress during continuous use. - Spring Hydraulic Cylinders

Spring hydraulic cylinders combine hydraulic action with spring mechanisms to provide a dual-action force. They are often used for counterbalancing and returning components to their original positions. These cylinders improve operational efficiency by reducing the hydraulic system’s workload. The spring mechanism adds additional force for smoother operation and is particularly useful in applications where quick resetting or return motion is required. - Power Pin Hydraulic Cylinders

Power pin hydraulic cylinders are specialized for locking and securing components of the truss arm during operation. They provide immense holding force, ensuring that all parts remain securely in place under stress. These cylinders are critical for maintaining the structural integrity of the crane during heavy lifting.

Truss Arm Crawler Crane Hydraulic Pin Shaft Cylinder Benefits

- Enhanced Load-Bearing Capacity

Pin shaft hydraulic cylinders are designed to handle extreme loads, making them ideal for truss arm crawler cranes. Their robust construction ensures they can bear significant weight without deformation, ensuring the crane operates reliably even in heavy-duty applications. This capability enhances productivity and ensures the safety of both the crane and the operators during demanding tasks. - Precision in Movement and Control

These pin shaft cylinders provide precise control over the truss arm's movement, allowing smooth angular or rotational motion. The pin shaft design enables accurate positioning during operations, which is essential for tasks requiring high precision. This level of control reduces operational errors, improves efficiency, and ensures a seamless workflow in challenging environments such as construction or mining. - Durability Under Harsh Conditions

Pin shaft hydraulic cylinders are built from high-strength materials that resist wear and corrosion, making them exceptionally durable in harsh working environments. They can withstand extreme temperatures, heavy vibrations, and exposure to moisture or chemicals. This durability reduces the frequency of replacements or repairs, ensuring long-term reliability and reduced maintenance costs. - Improved Stability and Safety

By providing stable and controlled motion, hydraulic pin shaft cylinders enhance the overall safety of crane operations. They minimize unwanted vibrations or instability, even when lifting asymmetrical loads. This stability reduces the risk of accidents, ensuring a safe working environment for operators and other workers at the site. - Efficient Force Distribution

The pin shaft design ensures that forces are evenly distributed across the truss arm and the hydraulic cylinder. This efficient force management prevents localized stress points, reducing wear on the crane’s structural components. As a result, the crane's lifespan is extended, and performance remains consistent over time. - Versatility in Applications

Pin shaft hydraulic cylinders are versatile and adaptable to various truss arm configurations and movements. Their design allows them to perform multiple functions, including lifting, tilting, and stabilizing. This versatility makes them suitable for a wide range of industries, including construction, heavy equipment manufacturing, and infrastructure development, offering flexibility and value in diverse operational scenarios.

Truss Arm Crawler Crane Pin Shaft Hydraulic Cylinder Troubleshooting

- Hydraulic Fluid Leaks

Leaks around the seals or connections of the pin shaft hydraulic cylinder can indicate damaged seals, loose fittings, or worn-out components. Regularly inspect these areas and replace faulty seals or tighten connections. Monitoring fluid levels and ensuring proper hydraulic pressure can prevent further issues caused by fluid leakage. - Cylinder Rod Sticking or Jerking

If the crane hydraulic cylinder rod exhibits sticking or uneven movement, this could be due to contamination within the hydraulic fluid or internal wear on the cylinder’s components. Clean or replace the fluid and inspect the cylinder for damaged parts. Regular maintenance of the hydraulic system helps avoid debris accumulation and ensures smooth rod operation. - Loss of Pressure or Inefficient Operation

A drop in hydraulic pressure can result from internal leaks, damaged seals, or a malfunctioning pump. Inspect the hydraulic cylinder for crane for internal wear, check all seals, and ensure the hydraulic pump is functioning efficiently. Addressing pressure loss promptly prevents performance degradation and reduces the risk of system failure. - Excessive Noise During Operation

Unusual noises, such as knocking or hissing, may indicate air trapped in the hydraulic system or misalignment of the cylinder. Bleed the system to remove air and realign the hydraulic cylinder crane to restore proper function. Regularly checking for loose components can minimize noise-related issues and prevent damage to the system. - Overheating of Hydraulic Cylinder

Overheating can occur due to continuous heavy operation, insufficient lubrication, or excessive friction caused by misaligned components. Check the hydraulic fluid levels and quality, ensure proper lubrication, and inspect for alignment issues. Installing cooling systems for high-demand operations can further reduce overheating risks. - Structural Damage to Cylinder or Pin Shaft

Cracks, bends, or deformation in the cylinder body or pin shaft can compromise performance and safety. Regularly inspect for visible damage and replace affected components immediately. Avoid overloading the crane, as excessive stress can lead to structural failures. Implementing load monitoring systems can help prevent recurring issues.

Additional information

| Edited by | Yjx |

|---|