Spring Hydraulic Cylinder for Truss Arm Crawler Crane

A spring hydraulic cylinder for a truss arm crawler crane is a specialized hydraulic component designed to provide buffering and controlled movement in the crane’s operations. It integrates a spring mechanism with hydraulic fluid dynamics to absorb shocks, reduce vibrations, and ensure smooth articulation of the crane’s truss arm, a lattice-structured boom used for heavy lifting.

A spring hydraulic cylinder for a truss arm crawler crane is a specialized hydraulic component designed to provide buffering and controlled movement in the crane’s operations. It integrates a spring mechanism with hydraulic fluid dynamics to absorb shocks, reduce vibrations, and ensure smooth articulation of the crane’s truss arm—a lattice-structured boom used for heavy lifting. They are crucial for stabilizing the arm during load handling, preventing abrupt movements, and enhancing safety on rugged terrains. This design ensures durability and precise control in demanding construction or industrial environments.

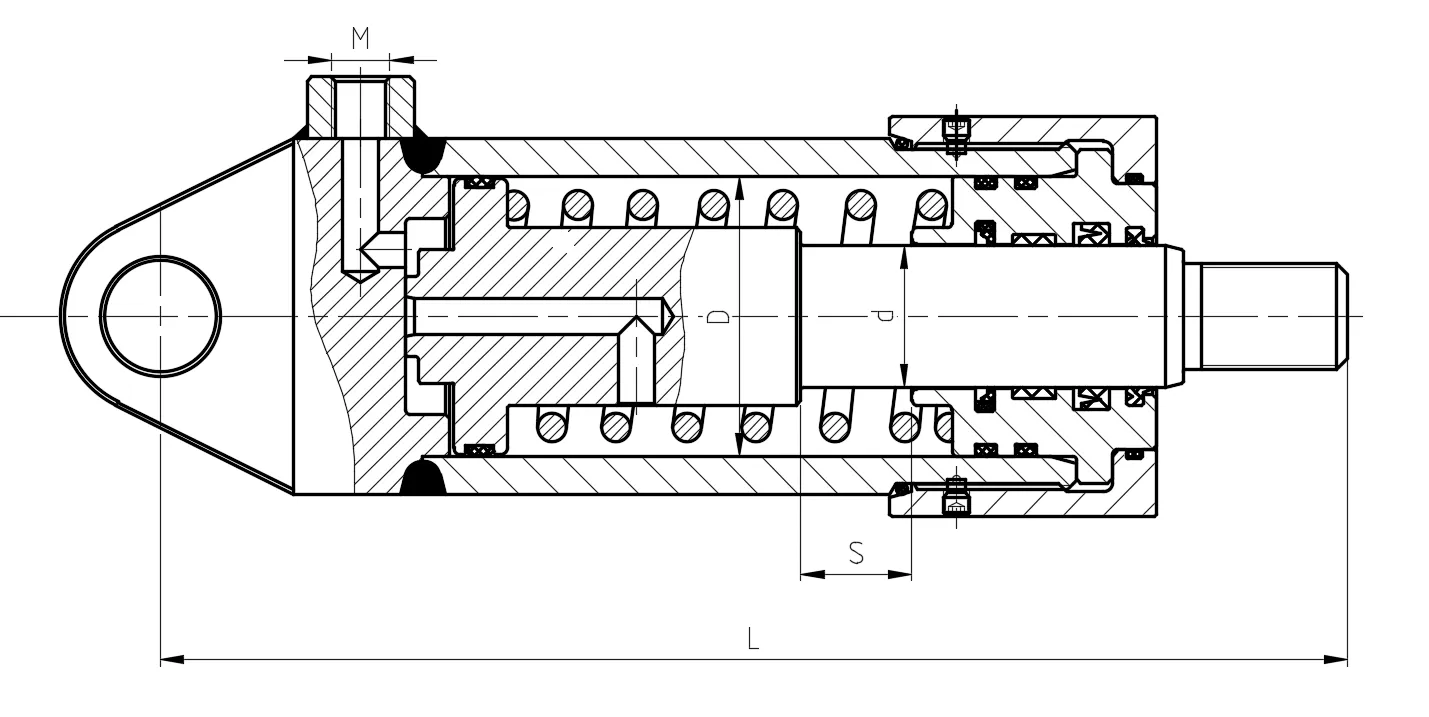

Spring Hydraulic Cylinder Dimensions

| Hydraulic Spring Cylinder |

|||||||

| Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| ZXYG24.01-00 | Φ63 | Φ32 | 25 | 267 | 4MPa | G1/4 | 6.5kg |

| Product Name: | Spring Hydraulic Cylinder |

| Function: | buffering effect |

| Cylinder diameter: | 50mm-63mm |

| Rod diameter: | 32mm |

| Travel: | 25mm-60mm |

| Maximum pressure: | 6MPa |

| Maximum thrust: | 19KN |

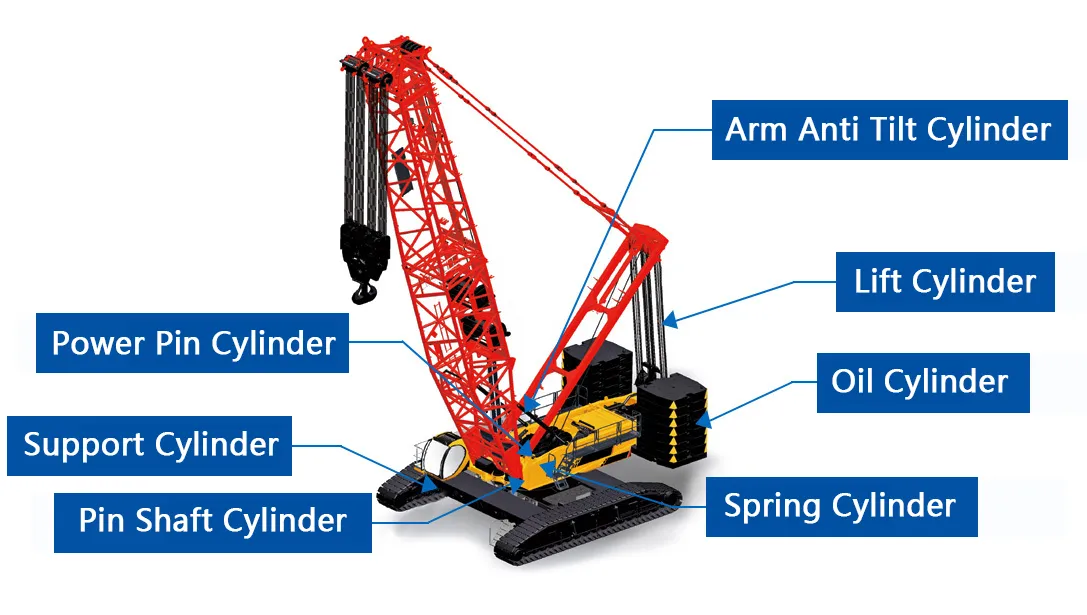

Truss Arm Crawler Crane Hydraulic Cylinder Types

- Hydraulic Support Cylinders

Hydraulic support cylinders provide essential stability to truss arm crawler cranes during operations. They are designed to bear heavy loads, ensuring the crane maintains balance and structural integrity on uneven or challenging terrains. - Hydraulic Lift Cylinders

Hydraulic lift cylinders are responsible for raising and lowering the truss arm of the crane. They offer precise control and powerful lifting capacity, enabling the safe and efficient handling of heavy materials or equipment. - Hydraulic Pin Shaft Cylinders

Hydraulic pin shaft cylinders serve as pivotal components for connecting and rotating parts of the crane. They ensure smooth articulation between the crane’s moving sections, allowing flexibility and accuracy during complex operations. - Hydraulic Spring Cylinders

Hydraulic spring cylinders combine hydraulic pressure with spring mechanisms to absorb shocks and vibrations. This reduces wear and tear on the crane’s structural components, improving operational safety and extending the equipment's service life. - Hydraulic Power Pin Cylinders

Hydraulic power pin cylinders are used for locking and securing different sections of the truss arm during operation. They provide the necessary strength and reliability to prevent unintended movements, enhancing operational precision and safety. - Hydraulic Arm Anti-Tilt Cylinders

Hydraulic arm anti-tilt cylinders are designed to prevent the crane’s arm from tilting or misaligning under heavy loads. They maintain proper alignment, ensuring the crane operates efficiently and safely in demanding conditions.

Truss Arm Crawler Crane Spring Hydraulic Cylinder Design Features

- Shock Absorption Capability

The spring hydraulic cylinder is designed with an integrated spring mechanism that efficiently absorbs shocks and vibrations. This feature reduces stress on the crane’s structure, enhancing stability and extending the lifespan of the equipment. - High-Pressure Performance

These cylinders are built to handle high hydraulic pressures, ensuring reliable performance even under heavy loads. Their robust construction allows them to operate efficiently in demanding environments without compromising safety or functionality. - Corrosion-Resistant Materials

Manufactured using high-grade, corrosion-resistant materials, the hydraulic spring cylinder is suitable for harsh outdoor conditions. This design feature ensures durability and prevents damage due to weather exposure or corrosive elements. - Precision-Controlled Movement

The design incorporates precision-engineered components for accurate control of the truss arm's movement. This allows operators to perform delicate lifting and positioning tasks with high accuracy, improving operational efficiency and safety. - Compact and Space-Efficient Design

The spring hydraulic cylinder is engineered to fit compactly within the crane’s truss arm structure. Its space-efficient design ensures it does not interfere with other components while maintaining full functionality. - Enhanced Energy Efficiency

The spring cylinder’s design optimizes energy usage by combining hydraulic pressure with spring-assisted force. This minimizes the crane’s overall power consumption while maintaining high performance during heavy-duty operations.

Truss Arm Crawler Crane Hydraulic Cylinder Applications

- Construction and Infrastructure Projects

Hydraulic cylinders are essential in truss arm crawler cranes used for heavy lifting in construction projects. They handle tasks such as lifting steel beams, concrete materials, and equipment, ensuring smooth and precise operations in demanding environments. - Mining and Quarrying Operations

In mining and quarrying, truss arm crawler cranes equipped with hydraulic cylinders assist in moving large rocks, minerals, and heavy machines. Their ability to handle extreme loads makes them crucial for material extraction and site preparation. - Oil and Gas Exploration

Crane hydraulic cylinders play a vital role in cranes used for offshore and onshore oil and gas operations. They support the lifting and positioning of drilling equipment, pipelines, and other heavy components in challenging and hazardous conditions. - Shipbuilding and Marine Applications

Truss arm crawler cranes with hydraulic spring cylinders are widely used in shipyards for assembling ship components. They lift and position heavy sections like hulls and engines, ensuring precise alignment in the construction or repair of vessels. - Renewable Energy Projects

In renewable energy fields, spring hydraulic cylinders in cranes are used to install wind turbines and solar panels. Their ability to handle heavy loads with precision is essential for assembling tall structures and sensitive equipment. - Industrial Manufacturing and Warehousing

Hydraulic cylinders in truss arm crawler cranes assist in material handling within manufacturing plants and warehouses. They enable the efficient movement of machinery, raw materials, and finished products, improving productivity and operational efficiency in industrial settings.

Additional information

| Edited by | Yjx |

|---|